- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA250-3MC Wheel Loader Operation and Maintenance Manual CEAM005802

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM005802

- Format: PDF

- Size: 2.4MB

- Number of Pages: 238

-

Model List:

- WA250-3MC Wheel Loader

- 1. INTRODUCTION

- 1.1. FORWARD

- 1.2. SAFETY INFORMATION

- 1.3. INTRODUCTION

- 1.3.1. INTENDED USE

- 1.3.2. FEATURES

- 1.3.3. BREAKING IN A NEW MACHINE

- 1.4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.4.1. MACHINE SERIAL NO. PLATE POSITION

- 1.4.2. ENGINE SERIAL NO. PLATE POSITION

- 1.4.3. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.5. CONTENTS

- 2. SAFETY

- 2.1. GENERAL PRECAUTIONS

- 2.1.1. SAFETY RULES

- 2.1.2. SAFETY FEATURES

- 2.1.3. UNAUTHORIZED MODIFICATION

- 2.1.4. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 2.1.5. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 2.1.6. MOUNTING AND DISMOUNTING

- 2.1.7. FIRE PREVENTION FOR FUEL AND OIL

- 2.1.8. PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURES

- 2.1.9. ASBESTOS DUST HAZARD PREVENTION

- 2.1.10. CRUSHING OR CUTTING PREVENTION

- 2.1.11. FIRE EXTINGUISHER AND FIRST AID KIT

- 2.1.12. PRECAUTIONS WHEN USING ROPS

- 2.1.13. PRECAUTIONS FOR ATTACHMENTS

- 2.1.14. PRECAUTION WHEN HANDLING ACCUMULATOR

- 2.2. PRECAUTIONS DURING OPERATION

- 2.2.1. BEFORE STARTING ENGINE

- 2.2.2. AFTER STARTING ENGINE

- 2.2.3. TRANSPORTATION

- 2.2.4. BATTERY

- 2.2.5. TOWING

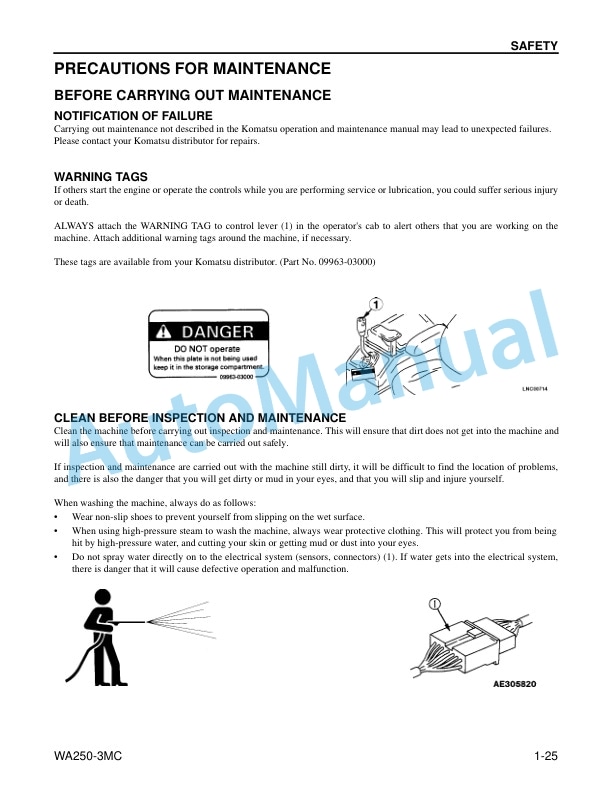

- 2.3. PRECAUTIONS FOR MAINTENANCE

- 2.3.1. BEFORE CARRYING OUT MAINTENANCE

- 2.3.2. DURING MAINTENANCE

- 2.3.3. TIRES

- 2.4. POSITION FOR ATTACHING SAFETY LABELS

- 2.4.1. POSITION FOR ATTACHING SAFETY LABELS

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. GENERAL VIEW OF MACHINE

- 3.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. METER, LAMPS

- 3.2.2. METER DISPLAY PORTION

- 3.2.3. SWITCHES

- 3.2.4. CONTROL LEVERS, PEDAL

- 3.2.5. STEERING COLUMN TILT LEVER

- 3.2.6. CAP WITH LOCK

- 3.2.7. SAFETY BAR

- 3.2.8. TOWING PIN

- 3.2.9. GREASE PUMP CLAMP AND RUBBER RING

- 3.2.10. BACKUP ALARM

- 3.2.11. FUSE

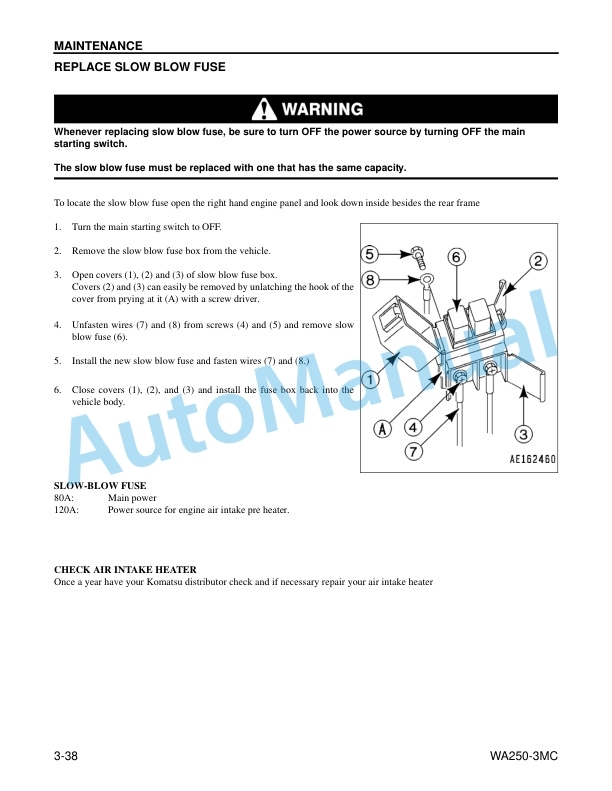

- 3.2.12. SLOW BLOW FUSE

- 3.2.13. STORAGE FOR THIS MANUAL

- 3.2.14. AUXILIARY POWER SOURCE

- 3.3. CHECK BEFORE STARTING ENGINE

- 3.3.1. WALK AROUND CHECK

- 3.3.2. CHECK BEFORE STARTING

- 3.3.3. BEFORE STARTING ENGINE OPERATIONS AND CHECKS

- 3.3.4. STARTING ENGINE

- 3.3.5. AFTER STARTING ENGINE OPERATIONS AND CHECKS

- 3.3.6. MOVING MACHINE

- 3.3.7. CHANGING GEAR SPEED

- 3.3.8. CHANGING DIRECTION

- 3.3.9. TURNING

- 3.3.10. STOPPING MACHINE

- 3.3.11. OPERATION OF WORK EQUIPMENT

- 3.3.12. WORK POSSIBLE USING WHEEL LOADER

- 3.3.13. PRECAUTIONS FOR OPERATION

- 3.3.14. ADJUSTING WORK EQUIPMENT POSTURE

- 3.3.15. PARKING MACHINE

- 3.3.16. CHECKS AFTER COMPLETION OF OPERATION

- 3.3.17. STOPPING ENGINE

- 3.3.18. CHECKS AFTER STOPPING ENGINE

- 3.3.19. LOCKING

- 3.4. TRANSPORTATION

- 3.4.1. LOADING, UNLOADING WORK

- 3.4.2. PRECAUTION FOR LOADING

- 3.4.3. PRECAUTION FOR LIFTING UP THE VEHICLE

- 3.5. COLD WEATHER OPERATIONS

- 3.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 3.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 3.5.3. AFTER COLD WEATHER

- 3.6. LONG TERM STORAGE

- 3.6.1. BEFORE STORAGE

- 3.6.2. DURING STORAGE

- 3.6.3. AFTER STORAGE

- 3.7. TROUBLESHOOTING

- 3.7.1. WHEN MACHINE RUNS OUT OF FUEL

- 3.7.2. TOWING THE MACHINE

- 3.7.3. IF BATTERY IS DISCHARGED

- 3.7.4. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. GUIDES TO MAINTENANCE

- 4.2. OUTLINES OF SERVICE

- 4.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 4.2.2. FUEL INJECTION PUMP

- 4.2.3. OUTLINE OF ELECTRIC SYSTEM

- 4.3. WEAR PARTS LIST

- 4.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 4.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 4.4.2. ENGINE OIL SPECIFICATIONS

- 4.4.3. DIESEL FUEL SPECIFICATIONS

- 4.4.4. COOLANT SPECIFICATIONS

- 4.5. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 4.5.1. INTRODUCTION OF NECESSARY TOOLS

- 4.5.2. TORQUE LIST

- 4.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 4.6.1. SAFETY CRITICAL PARTS

- 4.7. MAINTENANCE SCHEDULE CHART

- 4.7.1. MAINTENANCE SCHEDULE CHART

- 4.8. SERVICE PROCEDURES

- 4.8.1. INITIAL 250 HOURS SERVICE

- 4.8.2. WHEN REQUIRED

- 4.8.3. CHECK BEFORE STARTING

- 4.8.4. EVERY 50 HOURS SERVICE

- 4.8.5. EVERY 100 HOURS SERVICE

- 4.8.6. EVERY 250 HOURS SERVICE

- 4.8.7. EVERY 500 HOURS SERVICE

- 4.8.8. EVERY 1000 HOURS SERVICE

- 4.8.9. EVERY 2000 HOURS SERVICE

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 5.1.1. WA2503MC

- 6. OPTIONS, ATTACHMENTS

- 6.1. AVAILABLE ATTACHMENTS

- 6.2. BUCKETS AND TIRES SELECTION

- 6.3. AIR CONDITIONING

- 6.3.1. GENERAL LOCATIONS AND FUNCTION OF CONTROL PANEL

- 6.3.2. METHOD OF OPERATION

- 6.3.3. COOL BOX

- 6.4. HANDLING ECSS (Electronic Controlled Suspension System)

- 6.4.1. STRUCTURE AND FUNCTION OF ECSS

- 6.4.2. METHOD OF OPERATING ECSS

- 6.4.3. PRECAUTIONS WHEN OPERATING ECSS SWITCH

- 6.4.4. ACCUMULATOR PRECAUTIONS

- 6.4.5. RADIO

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF