- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA500-3H Wheel Loader Operation and Maintenance Manual VEAM500101

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: VEAM500101

- Format: PDF

- Size: 8.2MB

- Number of Pages: 290

-

Model List:

- WA500-3H Wheel Loader

- 1. Introduction

- 1.1. Foreword

- 1.1.1. EU Directives

- 1.2. Safety information

- 1.3. Introduction

- 1.3.1. Intended use

- 1.3.2. Features

- 1.3.3. Breakingin the machine

- 1.4. Location of plates, table to enter serial no. and distributor

- 1.4.1. Machine identification plate

- 1.4.2. Engine identification plate

- 1.5. Table of contents

- 1.6. Dimensions, weights and operating data

- 1.6.1. WA5003H Dimensions, weights and operating data

- 1.7. CEconforming equipment

- 1.7.1. CEconforming equipment part 1

- 1.7.2. Manufacturersupplied CEconforming equipment, according to document 41993H1160

- 1.8. Loading and securing

- 2. Safety

- 2.1. General safety measures

- 2.1.1. Safety instructions

- 2.1.2. Safety devices

- 2.1.3. Emergency exit

- 2.1.4. Clothing and personal protection

- 2.1.5. Machine modifications

- 2.1.6. Before you leave the drivers seat

- 2.1.7. Mounting and dismounting

- 2.1.8. Fire prevention and fire fighting

- 2.1.9. Protection against asbestos dust

- 2.1.10. Protection against injuries

- 2.1.11. Working at high temperatures

- 2.1.12. Rollover protection system (ROPS)

- 2.1.13. Attachment for protection against falling objects (FOPS)

- 2.1.14. Attachments

- 2.1.15. Battery

- 2.2. Safety precautions during operation

- 2.2.1. Before you start the engine

- 2.2.2. Machine operation

- 2.2.3. Transport

- 2.3. Precautions for maintenance

- 2.3.1. Personnel

- 2.3.2. Before carrying out maintenance

- 2.3.3. During maintenance

- 2.3.4. Tyres

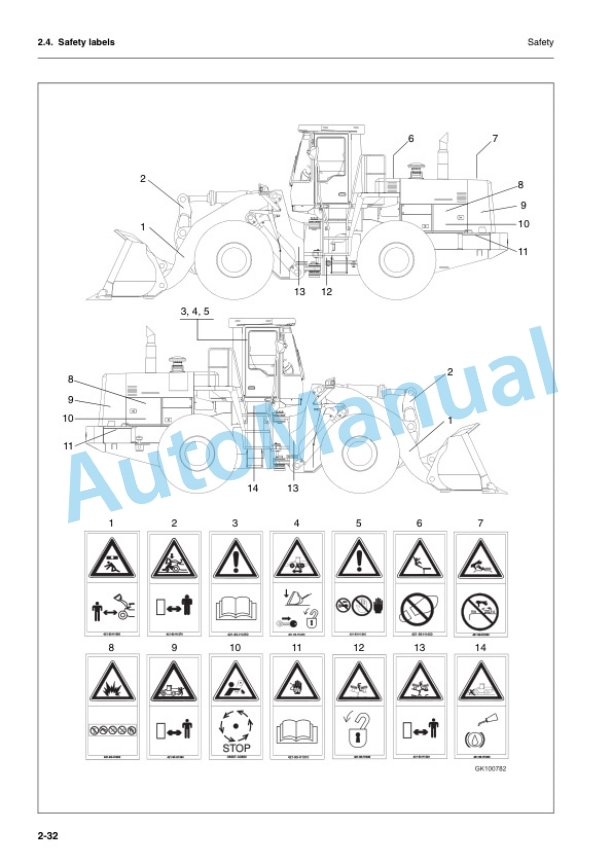

- 2.4. Safety labels

- 2.4.1. Position of safety labels

- 3. Operation

- 3.1. General view

- 3.1.1. General view of the machine

- 3.1.2. Control elements and measuring instruments

- 3.2. Description of the individual elements

- 3.2.1. Control monitor

- 3.2.2. Switches

- 3.2.3. Control levers and pedals

- 3.2.4. Steering column tilt lever

- 3.2.5. Cap with lock

- 3.2.6. Safety bar

- 3.2.7. Towing pin

- 3.2.8. Backup alarm

- 3.2.9. Fuses

- 3.2.10. Slowblow fuses

- 3.2.11. Air conditioning

- 3.3. Operation

- 3.3.1. Prestart checks

- 3.3.2. Starting the engine

- 3.3.3. Operation and checks after starting the engine

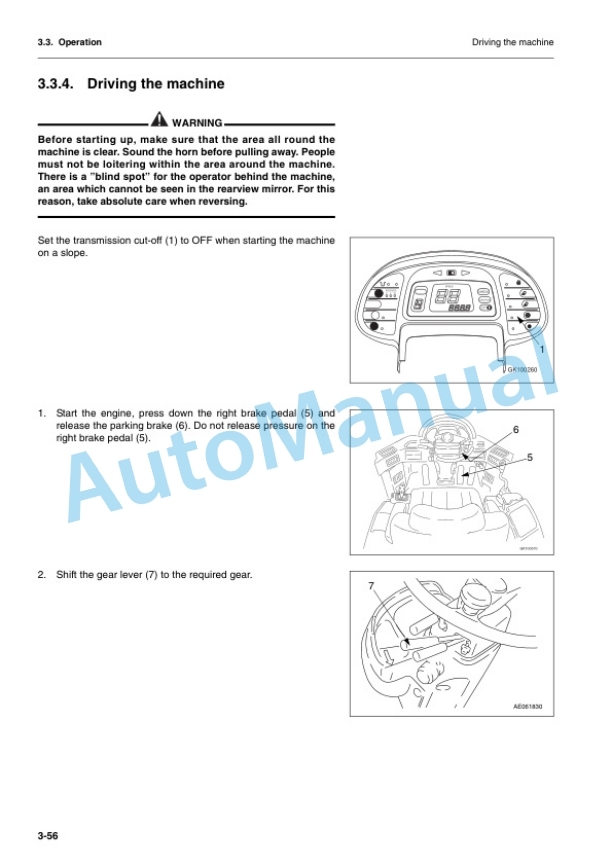

- 3.3.4. Driving the machine

- 3.3.5. Gear change

- 3.3.6. Changing direction

- 3.3.7. Turning and steering

- 3.3.8. Stopping the machine

- 3.3.9. Operating the work equipment

- 3.3.10. Wheel loader operations

- 3.3.11. Precautionary measures during operation

- 3.3.12. Adjusting the position of the work equipment

- 3.3.13. Parking the machine

- 3.3.14. Stopping the engine

- 3.3.15. Check after stopping the engine

- 3.3.16. Locking

- 3.3.17. Tyre handling

- 3.4. Transport

- 3.4.1. Loading, unloading

- 3.4.2. Precautions for loading

- 3.4.3. Precautions during transport

- 3.4.4. Removing / Fitting attachment

- 3.5. Cold weather operation

- 3.5.1. Precautions for low temperatures

- 3.5.2. Precautions after completion of work

- 3.5.3. After the cold weather period

- 3.6. Longterm storage

- 3.6.1. Before storage

- 3.6.2. During storage

- 3.6.3. After storage

- 4. Troubleshooting

- 4.1. When the machine runs out of fuel

- 4.2. Central lubrication system

- 4.2.1. No grease emerging at the lubrication points

- 4.2.2. The pump does not switch on

- 4.3. Towing the machine

- 4.3.1. Engine can still be used

- 4.3.2. Engine cannot be used

- 4.3.3. Releasing the parking brake (Engine not running)

- 4.3.4. Emergency travel operation

- 4.4. If battery is discharged

- 4.4.1. Precautions for charging the battery

- 4.4.2. Starting the engine with a booster cable

- 4.5. For insufficient braking effect

- 4.5.1. Checking the brake function

- 4.5.2. Checking the parking brake function

- 4.6. Other troubles

- 4.6.1. Electrical system

- 4.6.2. Chassis

- 4.6.3. Engine

- 5. Maintenance

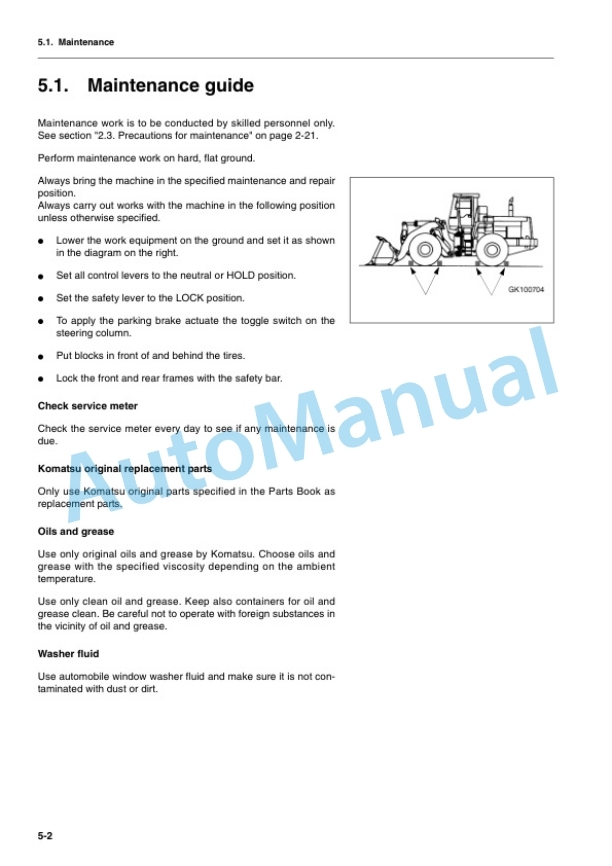

- 5.1. Maintenance guide

- 5.2. Maintenance basics

- 5.2.1. Oil, fuel and coolant specifications

- 5.2.2. Specifications of the electrical system

- 5.3. Wearing parts list

- 5.3.1. Wearing parts

- 5.4. Lubricants and operating means

- 5.4.1. Lubrication chart

- 5.4.2. Lubricants, fuels and filling capacities

- 5.5. Tools and standard tightening torques (bolts, nuts)

- 5.5.1. Introduction of recommended tools

- 5.5.2. Torque list

- 5.6. Periodical replacement of safetycritical parts

- 5.6.1. Critical parts

- 5.7. Maintenance schedule chart

- 5.7.1. Maintenance rate

- 5.8. Service procedure

- 5.8.1. Initial 50 hours service

- 5.8.2. Initial 250 hours service

- 5.8.3. Maintenance upon demand

- 5.8.4. Checks before starting

- 5.8.5. Every 50 hours service

- 5.8.6. Every 100 hours service

- 5.8.7. Every 250 service hours

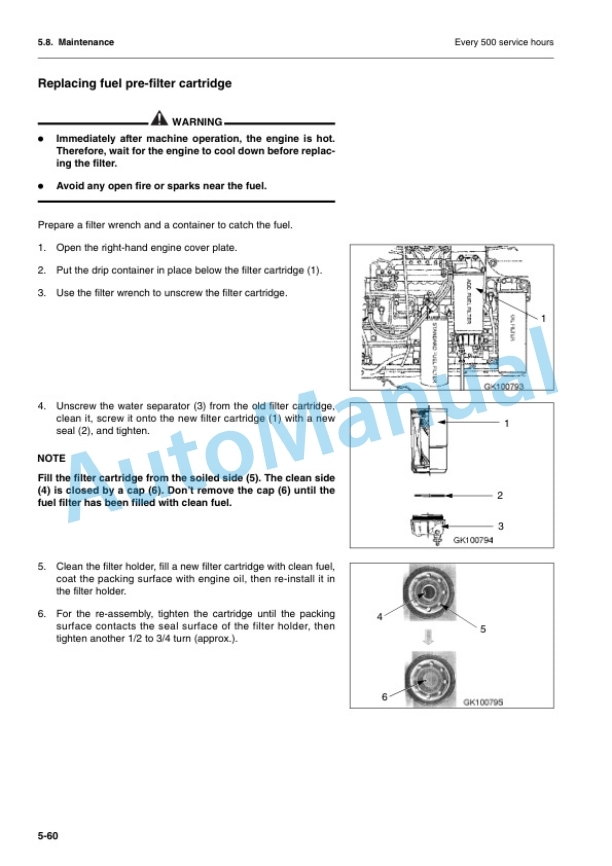

- 5.8.8. Every 500 service hours

- 5.8.9. Every 1000 service hours

- 5.8.10. Every 2000 service hours

- 5.8.11. Every 4000 service hours

- 5.8.12. Every 8000 service hours

- 6. Technical data

- 6.1. Technical data

- 6.2. Noise emission levels

- 6.3. Vibration levels

- 6.3.1. Operating condition

- 6.3.2. Guide to Reduce Vibration Levels on Machine

- 6.4. Limit values for slopes

- 7. Special equipment and attachments

- 7.1. ECSSelectronics

- 7.1.1. Structure and functioning principle of the ECSSelectronics

- 7.1.2. Precautionary measures for switching on the ECSSelectronics

- 7.1.3. Operating the ECSSelectronics

- 7.1.4. Precautions when handling the accumulator

- 7.2. Auto positioning

- 7.2.1. Auto positioning control

- 7.2.2. Setting hold points of auto positioning

- 7.2.3. Auto positioning calibration

- 7.3. Joystick steering system

- 7.3.1. Structure and function of joystick steering

- 7.3.2. Operation method of joystick steering system

- 7.3.3. Precautions for steering with joystick

- 7.3.4. Adjustment of joystick console

- 7.3.5. Adjustment operators seat

- 8. Index

- 9. Notes

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF