- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WD900-3 Wheel Dozer Operation and Maintenance Manual SEAMW00203

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAMW00203

- Format: PDF

- Size: 15.7MB

- Number of Pages: 261

-

Model List:

- WD900-3 Wheel Dozer

- 1. MAIN MENU

- 2. COVER

- 3. FOREWORD

- 4. SAFETY INFORMATION

- 5. INTRODUCTION

- 6. LOCATION OF PLATES, TABLES TO ENTER SERIAL NO. AND DISTRIBUTOR

- 7. CONTENTS

- 8. SAFETY

- 8.1. GENERAL PRECAUTIONS

- 8.2. PRECAUTIONS DURING OPERATION

- 8.2.1. BEFORE STARTING ENGINE

- 8.2.2. AFTER STARTING ENGINE

- 8.2.3. TRASPORTATION

- 8.2.4. BATTERY

- 8.2.5. TOWING

- 8.3. PRECAUTIONS FOR MAINTENANCE

- 8.3.1. BEFORE CARRYING OUT MAINTENANCE

- 8.3.2. DURING MAINTENANCE

- 8.3.3. TIRES

- 8.4. POSITION FOR ATTACHING SAFETY LABELS

- 9. OPERATION

- 9.1. GENERAL VIEW

- 9.1.1. GENERAL VIEW OF MACHINE

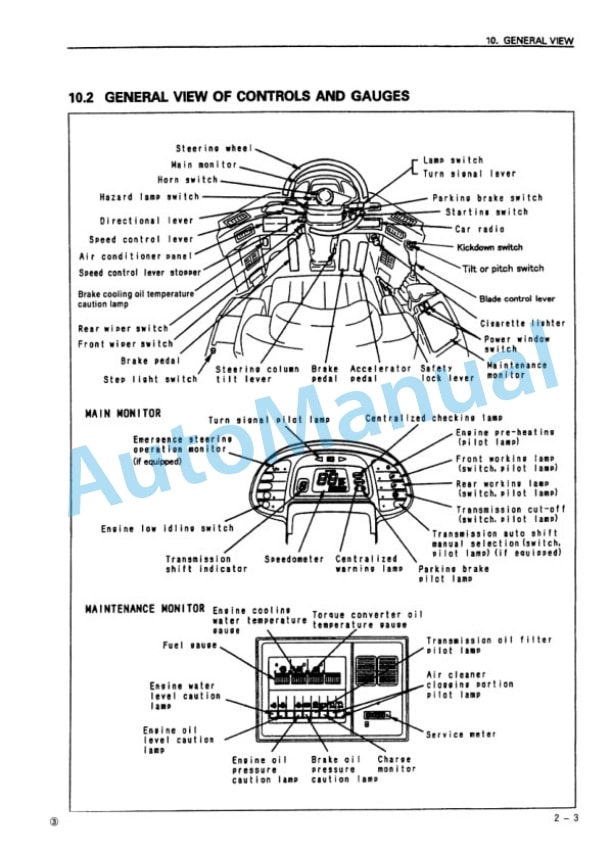

- 9.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 9.2. EXPLANATION OF COMPONENTS

- 9.2.1. MACHINE MONITOR

- 9.2.2. SWITCHES

- 9.2.3. CONTROL LEVERS, PEDALS

- 9.2.4. STEERING COLUMN TILT LEVER

- 9.2.5. CAP WITH LOCK

- 9.2.6. SAFETY BAR

- 9.2.7. GREASE PUMP

- 9.2.8. BACKUP ALARM

- 9.2.9. DOOROPEN LOCK

- 9.2.10. TOOL BOX

- 9.2.11. FUEL STOP LEVER

- 9.2.12. FUSE

- 9.2.13. SLOWBLOW FUSE

- 9.2.14. LUNCH BOX TRAY

- 9.2.15. STORAGING PLACE OF THIS MANUAL

- 9.2.16. TAKING OFF POWER

- 9.2.17. PRECAUTIONS WHEN HANDLING ACCUMULATOR

- 9.3. OPERATION

- 9.3.1. CHECK BEFORE STARTING ENGINE

- 9.3.2. STARTING ENGINE

- 9.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 9.3.4. MOVING MACHINE OFF

- 9.3.5. CHANGING GEAR SPEED

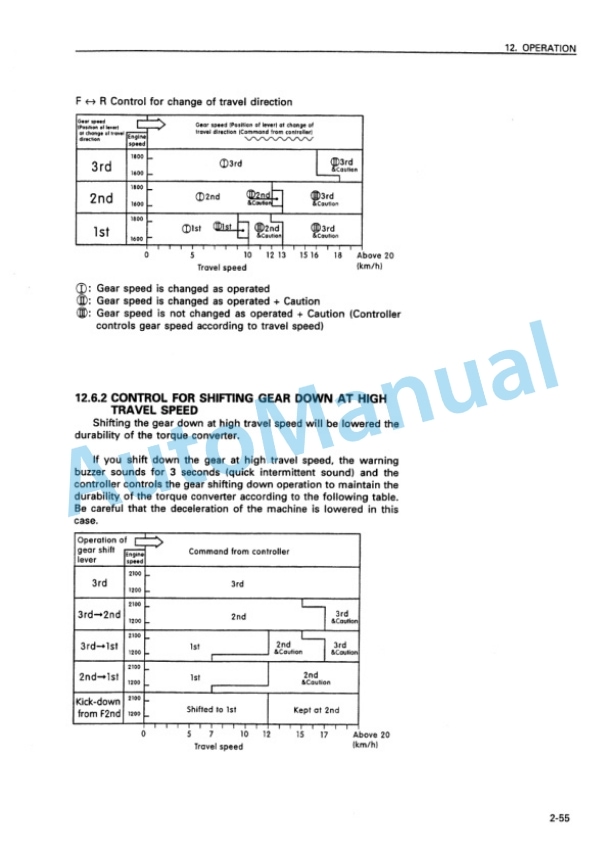

- 9.3.6. CHANGING DIRECTION

- 9.3.7. TURNING

- 9.3.8. STOPPING MACHINE

- 9.3.9. OPERATION OF WORK EQUIPMENT

- 9.3.10. WORK POSSIBLE USING WHEEL DOZER

- 9.3.11. PRECAUTIONS FOR OPERATION

- 9.3.12. PARKING MACHINE

- 9.3.13. CHECK AFTER COMPLETION OF OPERATION

- 9.3.14. STOPPING ENGINE

- 9.3.15. CHECK AFTER STOPPING ENGINE

- 9.3.16. LOCKING

- 9.3.17. HANDLING THE TIRES

- 9.4. TRANSPORTATION

- 9.4.1. LIFTING MACHINE

- 9.5. COLD WEATHER OPERATION

- 9.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 9.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 9.5.3. AFTER COLD WEATHER

- 9.5.4. WARMINGUP OPERATION FOR STEERING HYDRAULIC CIRCUIT IN COLD WEATHER

- 9.6. LONGTERM STORAGE

- 9.6.1. BEFORE STORAGE

- 9.6.2. DURING STORAGE

- 9.6.3. AFTER STORAGE

- 9.7. TROUBLESHOOTING

- 9.7.1. WHEN MACHINE RUNS OUT OF FUEL

- 9.7.2. TOWING THE MACHINE

- 9.7.3. IF BATTERY IS DISCHARGED

- 9.7.4. OTHER TROUBLE

- 10. MAINTENANCE

- 10.1. GUIDES TO MAINTENANCE

- 10.2. OUTLINES OF SERVICE

- 10.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMANCE OIL CLINIC

- 10.2.2. OUTLINE OF ELECTRIC SYSTEM

- 10.3. WEAR PARTS LIST

- 10.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 10.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 10.5.1. INTRODUCTION OF NECESSARY TOOLS

- 10.5.2. TORQUE LIST

- 10.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

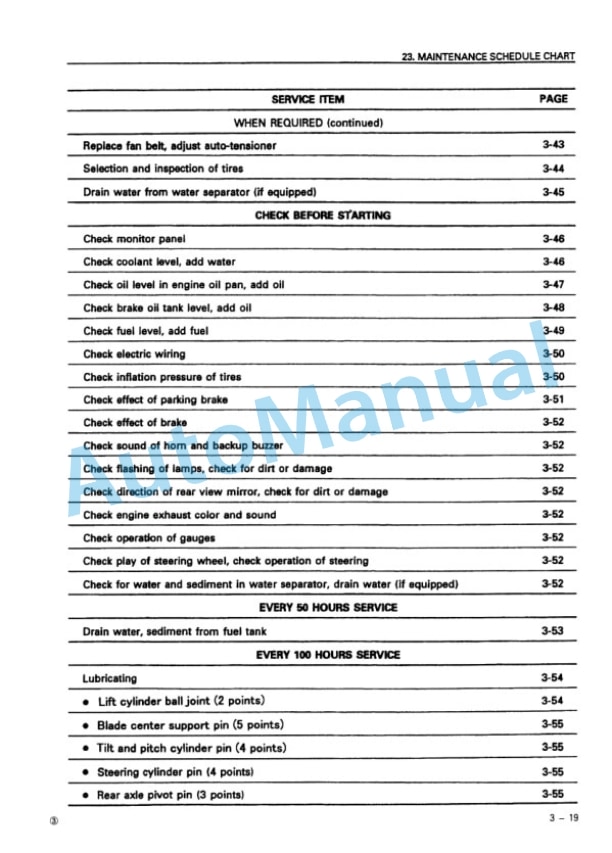

- 10.7. MAINTENANCE SCHEDULE CHART

- 10.7.1. MAINTENANCE SCHEDULE CHART

- 10.8. SERVICE PROCEDURE

- 10.8.1. INITIAL 250 HOURS SERVICE

- 10.8.1.1. REPLACE FUEL FILTER CARTRIDGE

- 10.8.1.2. REPLACE TRANSMISSION OIL FILTER ELEMENT

- 10.8.1.3. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 10.8.2. WHEN REQUIRED

- 10.8.2.1. CHECK, CLEAN, OR REPLACE AIR CLEANER ELEMENT

- 10.8.2.2. CLEAN INSIDE OF COOLING SYSTEM

- 10.8.2.3. CHECK TRANSMISSION OIL LEVEL, ADD OIL

- 10.8.2.4. CHECK AXLE OIL LEVEL, ADD OIL

- 10.8.2.5. CHECK AXLE CASE BREATHER

- 10.8.2.6. CHECK WINDOW WASHING FLUID LEVEL, ADD FLUID

- 10.8.2.7. CLEAN CONDENSER OF AIR CONDITIONER (IF EQUIPPED)

- 10.8.2.8. CLEAN RADIATOR FINS

- 10.8.2.9. CLEAN OIL COOLER FINS (BRAKE COOLING OIL COOLER AND TORQUE CONVERTER OIL COOLER (IF EQUIPPED))

- 10.8.2.10. CHECK ELETRICAL INTAKE AIR HEATER

- 10.8.2.11. REPLACING END BIT AND CUTTING EDGE

- 10.8.2.12. LUBRICATING

- 10.8.2.13. CHECK AIR CONDITIONER (IF EQUIPPED)

- 10.8.2.14. ADJUST PARKING BRAKE

- 10.8.2.15. BLEEDING AIR FROM BRAKE HYDRAULIC CIRCUIT

- 10.8.2.16. BLEEDING AIR FROM PPC CIRCUIT

- 10.8.2.17. REPLACE SLOW BLOW FUSE

- 10.8.2.18. BLEEDING AIR FROM HYDRAULIC TANK

- 10.8.2.19. REPLACE FAN BELT, ADJUST AUTOTENSIONER

- 10.8.2.20. SELECTION AND INSPECTION OF TIRES

- 10.8.2.21. DRAIN WATER FROM WATER SEPARATOR (IF EQUIPPED)

- 10.8.3. CHECK BEFORE STARTING

- 10.8.3.1. CHECK MONITOR PANEL

- 10.8.3.2. CHECK COOLANT LEVEL, ADD WATER

- 10.8.3.3. CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL

- 10.8.3.4. CHECK BRAKE OIL TANK LEVEL, ADD OIL

- 10.8.3.5. CHECK FUEL LEVEL, ADD FUEL

- 10.8.3.6. CHECK ELECTRIC WIRING

- 10.8.3.7. CHECK INFLATION PRESSURE OF TIRES

- 10.8.3.8. CHECK EFFECT OF PARKING BRAKE

- 10.8.3.9. CHECK EFFECT OF BRAKE

- 10.8.3.10. CHECK SOUND OF HORN AND BACKUP BUZZER

- 10.8.3.11. CHECK FLASHING OF LAMPS, CHECK FOR DIRT OR DAMAGE

- 10.8.3.12. CHECK DIRECTION OF REAR VIEW MIRROR, CHECK FOR DIRT OR DAVAGE

- 10.8.3.13. CHECK ENGINE EXHAUST COLOR AND SOUND

- 10.8.3.14. CHECK OPERATION OF GAUGES

- 10.8.3.15. CHECK PLAY OF STEERING WHEEL, CHECK OPERATION OF STEERING

- 10.8.3.16. CHECK FOR WATER AND SEDIMENT IN WATER SEPARATOR, DRAIN WATER (IF EQUIPPED)

- 10.8.4. EVERY 50 HOURS SERVICE

- 10.8.4.1. DRAIN WATER, SEDIMENT FROM FUEL TANK

- 10.8.5. EVERY 100 HOURS SERVICE

- 10.8.5.1. LUBRICATING

- 10.8.5.2. CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

- 10.8.5.3. CLEAN ELEMENT IN AIR CONDITIONER FRESH AIR FILTER (IF EQUIPPED)

- 10.8.6. EVERY 250 HOURS SERVICE

- 10.8.6.1. CHECK BATTERY ELECTROLYTE LEVEL

- 10.8.6.2. CHECK ALTERNATOR BELT TENSION, ADJUST

- 10.8.6.3. CHECK FOR LOOSE WHEEL HUB NUTS, TIGHTEN

- 10.8.6.4. CLEAN ELEMENT IN AIR CONDITIONER RECIRCULATION FILTER (IF EQUIPPED)

- 10.8.6.5. LUBRICATE OIL COOLER FAN BEARING (1 POINT)

- 10.8.6.6. CHECK, AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST (IF EQUIPPED)

- 10.8.6.7. CHECK FRAME

- 10.8.7. EVERY 500 HOURS SERVICE

- 10.8.7.1. CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE

- 10.8.7.2. REPLACE FUEL FILTER CARTRIDGE

- 10.8.7.3. REPLACE TRANSMISSION OIL FILTER ELEMENT

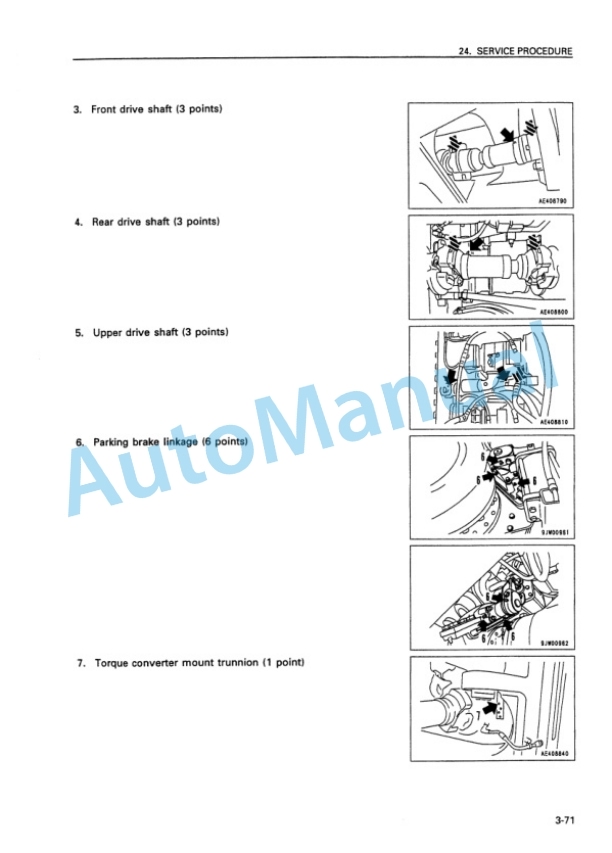

- 10.8.7.4. LUBRICATE CENTER DRIVE SHAFT (3 POINTS)

- 10.8.7.5. CHECK FAN BELT FOR WEAR

- 10.8.8. EVERY 1000 HOURS SERVICE

- 10.8.8.1. CHANGE OIL IN TRANSMISSION CASE, CLEAN STRAINER

- 10.8.8.2. CLEAN TRANSMISSION CASE BREATHER

- 10.8.8.3. LUBRICATING

- 10.8.8.4. CHECK TIGHTENING PART OF TURBOCHARGER

- 10.8.8.5. CLEAN FUEL STRAINER

- 10.8.8.6. TIGHTEN ROPS CANOPY (IF EQUIPPED)

- 10.8.8.7. REPLACE CORROSION RESISTOR CARTRIDGE

- 10.8.9. EVERY 2000 HOURS SERVICE

- 10.8.9.1. CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC FILTER ELEMENT

- 10.8.9.2. CLEAN HYDRAULIC TANK STRAINER

- 10.8.9.3. REPLACE HYDRAULIC TANK BREATHER ELEMENT

- 10.8.9.4. CHANGE AXLE OIL, REPLACE BRAKE COOLING OIL FILTER CARTRIDGE

- 10.8.9.5. REPLACE AIR CONDITIONER FILTER (IF EQUIPPED)

- 10.8.9.6. CLEAN PPC CIRCUIT STRAINER

- 10.8.9.7. CHECK WEAR OF BRAKE DISCS

- 10.8.9.8. CHECK ALTERNATOR, STARTING MOTOR

- 10.8.9.9. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 10.8.9.10. CLEAN AND CHECK TURBOCHARGER ROTOR

- 10.8.9.11. CHECK ACCUMULATOR

- 10.8.10. EVERY 4000 HOURS SERVICE

- 10.8.10.1. CHECK WATER PUMP

- 10.8.10.2. CHECK ENGINE VIBRATION DAMPER

- 10.8.10.3. CHECK FAN PULLEY AND TENSION PULLEY

- 10.8.10.4. CHECK AIR COMPRESSOR, ADJUST

- 10.8.10.5. CHECK INJECTION PUMP RACK RUBBER BOOT , REPLACE

- 11. SPECIFICATIONS

- 11.1. SPECIFICATION

- 12. OPTIONS, ATTACHMENTS

- 12.1. OPTIONAL PARTS AND ATTACHMENTS

- 12.2. HANDLING AUTO SHIFT SYSTEM

- 12.2.1. AUTOMATIC SHIFT SYSTEM

- 12.2.2. PRECAUTIONS WHEN CHANGING DIRECTION

- 12.3. HANDLING JOYSTICK STEERING SYSTEM

- 12.3.1. EXPLANATION OF COMPONENTS

- 12.3.2. STRUCTURE AND FUNCTION OF JOYSTICK STEERING

- 12.3.3. OPERATION METHOD OF JOYSTICK STEERING SYSTEM

- 12.3.4. PRECAUTIONS FOR STEERING WITH JOYSTICK

- 12.3.5. ADJUSTMENT OF JOYSTICK CONSOLE

- 12.3.6. ADJUSTMENT OPERATORS SEAT

- 12.4. MAIN MONITOR FAILURE DISPLAY

- 12.4.1. MAIN MONITOR FAILURE DISPLAY

- 12.4.2. ERROR CODES LIST INDICATED ON MAIN MONITOR

- 12.5. AIR CONDITIONER

- 12.5.1. GENERAL LOCATIONS AND FUNCTION OF CONTROL PANEL

- 12.5.2. METHOD OF OPERATION

- 12.6. AM/FM CAR RADIO

- 12.6.1. EXPLANATION OF COMPONENTS

- 12.6.2. METHOD OF USE

- 12.6.3. PRECAUTIONS WHEN USING

- 12.7. AM/FM RADIOCASSETTE STEREO

- 12.7.1. EXPLANATION OF COMPONENTS

- 12.7.2. OPERATION METHOD

- 12.7.3. PRECAUTIONS WHEN USING

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF