- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu XT430-2, XT430L-2, XT450L-2 Crawler Feller Buncher Operation and Maintenance Manual CEAM029102

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM029102

- Format: PDF

- Size: 20.2MB

- Number of Pages: 242

-

Model List:

- XT430-2 Crawler Feller Buncher

- XT430L-2 Crawler Feller Buncher

- XT450L-2 Crawler Feller Buncher

- 1. CEAM029102 OPERATION AND MAINTENANCE MANUAL

- 1.1. INTRODUCTION

- 1.1.1. FOREWORD

- 1.1.2. SAFETY INFORMATION

- 1.1.3. INTRODUCTION

- 1.1.3.1. Machine Orientation

- 1.1.3.2. Protective Structure

- 1.1.3.3. Breakingin The New Machine

- 1.1.3.4. Product Information

- 1.1.3.5. Your Machine Serial Numbers And Distributor

- 1.1.4. Table of contents

- 1.2. SAFETY

- 1.2.1. SAFETY AND WARNING DECALS

- 1.2.1.1. Location of the Safety Decals

- 1.2.2. OPERATIONAL SAFETY

- 1.2.2.1. Unauthorized Modifications

- 1.2.2.2. Before Starting the Engine

- 1.2.2.3. Observe General Safety Rules

- 1.2.2.4. Engine Ventilation

- 1.2.2.5. Fuel, Oil And Hydraulic Fluid Fire Hazards

- 1.2.2.6. Jump Starting or Charging Batteries

- 1.2.2.7. Travel Controls May Produce Reversed Operations

- 1.2.2.8. Travel Precautions

- 1.2.2.9. Operate Carefully on Snow and Ice and in Very Cold Temperatures

- 1.2.2.10. Parking the Machine

- 1.2.2.11. Do Not Disassemble Recoil Springs

- 1.2.2.12. Accumulator

- 1.2.2.13. Handling Gas Spring

- 1.2.2.14. Shut Down Control Functions

- 1.2.2.15. Emergency Stop Function

- 1.2.3. ADDITIONAL SAFETY EQUIPMENT

- 1.2.3.1. Do Not Alter or Modify the ROPS, FOPS, OPS

- 1.2.3.2. Seat Belt Must Be Used at All Times

- 1.2.3.3. Maintain Standard Safety Equipment in Good Condition

- 1.2.4. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 1.2.4.1. General Operator Precautions

- 1.2.4.2. Mounting and Dismounting Precautions

- 1.2.4.3. Handrails and Steps

- 1.2.4.4. No Jumping On or Off Machine

- 1.2.5. FIRE PREVENTION

- 1.2.5.1. Fire Caused by Accumulation of Flammable Material

- 1.2.5.2. Fire Caused by Fuel, Oil or Grease

- 1.2.5.3. Fire Coming from Electrical Wiring

- 1.2.5.4. Fire Coming from Hydraulic Line

- 1.2.5.5. Best Practices

- 1.2.5.6. Action if Smoke or Fire Occurs

- 1.2.5.7. What to Do After Fire

- 1.2.5.8. Fire Extinguisher and First Aid Kit

- 1.2.5.9. Action After Fire Suppression Activation

- 1.2.5.10. Ansul Fire Suppression System (Optional)

- 1.2.5.11. Action After Fire Suppression Activation

- 1.2.5.12. Fire Suppression System Owners Manual

- 1.3. OPERATION

- 1.3.1. General Orientation

- 1.3.1.1. Operation precautions

- 1.3.1.2. General

- 1.3.1.3. Before Starting the Engine

- 1.3.1.4. Before Beginning To Work

- 1.3.1.5. Attachment Safety

- 1.3.1.6. During Machine Operation

- 1.3.1.7. Parking the Machine

- 1.3.2. SERVICE AND MAINTENANCE PRECAUTIONS

- 1.3.2.1. General

- 1.3.2.2. Towing the Machine

- 1.3.2.3. Cooling and Hydraulic Systems

- 1.3.2.4. Track Tension Adjustments Require Caution

- 1.3.2.5. Diesel Fuel

- 1.3.2.6. Batteries

- 1.3.3. FIRE PREVENTION IN THE FIELD

- 1.3.3.1. Fire Prevention Tips in the Field

- 1.3.3.2. Fire Prevention in the Shop

- 1.3.4. SHIPPING AND TRANSPORTATION

- 1.3.4.1. Obey State and Local OvertheRoad Regulations

- 1.3.5. OPERATING CONTROLS

- 1.3.5.1. Operators Cab

- 1.3.5.2. Ansul Fire Suppression System (Optional)

- 1.3.6. IQAN CONTROL SYSTEM

- 1.3.6.1. Main Screen Display

- 1.3.6.2. Main Menu Screen Selector

- 1.3.6.3. Info Menu

- 1.3.6.4. Measure Menu

- 1.3.6.5. Adjust Menu

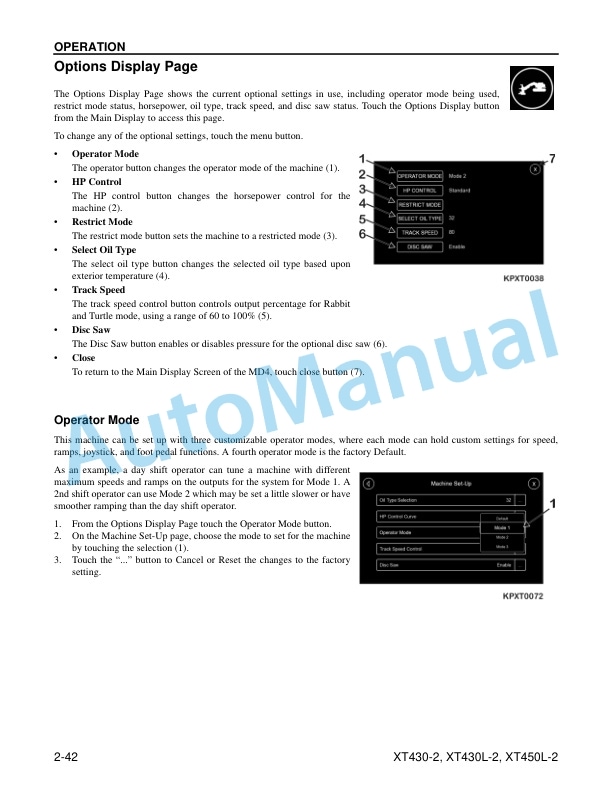

- 1.3.6.6. Options Display Page

- 1.3.6.7. Information Display Page

- 1.3.6.8. Engine Display Page

- 1.3.6.9. Faults Display Page

- 1.3.6.10. Operating the IQAN MDM Monitor

- 1.3.7. before starting machine

- 1.3.7.1. Truck Drivers Starting, Driving and Boom Operation Instructions

- 1.3.7.2. Tracked Feller Buncher / Harvester Daily Inspection

- 1.3.7.3. General PreStart Machine Inspection

- 1.3.7.4. New Machine Breakin Procedures

- 1.3.8. Starting the Machine

- 1.3.8.1. Cold Weather Starting

- 1.3.8.2. Jump Starting the Engine

- 1.3.8.3. Engine and Hydraulic Warming Procedures

- 1.3.8.4. Travel Controls

- 1.3.8.5. Travel Speed

- 1.3.8.6. Track/Parking Brakes

- 1.3.8.7. Preventing Repetitive Strain Injuries

- 1.3.8.8. Controlling the Front End Implements

- 1.3.8.9. Control Pattern Diagrams

- 1.3.8.10. Front End Attachment Movements

- 1.3.8.11. General Machine Operating Instructions

- 1.3.8.12. Changing Direction Forward and Reverse

- 1.3.8.13. Frozen Ground Conditions

- 1.3.8.14. Parking the Machine

- 1.3.8.15. Cleaning the Tracks

- 1.3.8.16. Stopping the Engine

- 1.3.8.17. Lowering Work Equipment Without Engine Power

- 1.4. MAINTENANCE

- 1.4.1. MAINTENANCE INFORMATION

- 1.4.1.1. Service Meter Reading

- 1.4.1.2. Komatsu Genuine Replacement Parts

- 1.4.1.3. Komatsu Genuine Lubricants

- 1.4.1.4. Fresh and Clean Lubricants

- 1.4.1.5. Check Drained Oil and Used Filter

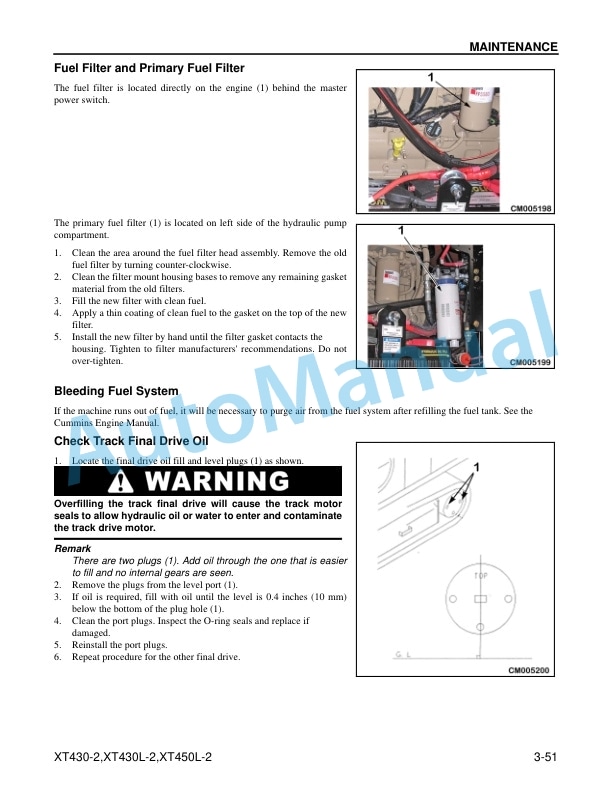

- 1.4.1.6. Fuel Strainer

- 1.4.1.7. Welding Instructions

- 1.4.1.8. Do Not Drop Things Inside Machine

- 1.4.1.9. Selecting Fuel and Lubricants to Match Ambient Temperature

- 1.4.1.10. Dusty Jobsite

- 1.4.1.11. Avoid Mixing Lubricants

- 1.4.1.12. Locking the Inspection Covers

- 1.4.1.13. Hydraulic System Air Bleeding

- 1.4.1.14. Hydraulic Hose Installation

- 1.4.1.15. Checks after Inspection and Maintenance Works

- 1.4.2. LUBRICANTS, COOLANT AND FILTERS

- 1.4.2.1. Outline of Service

- 1.4.2.2. Handling Oil, Fuel, Coolant, and Performing Oil Clinic

- 1.4.2.3. Electric System Maintenance

- 1.4.2.4. Handling Hydraulic System

- 1.4.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 1.4.4. LUBRICANT AND FILL CAPACITIES

- 1.4.4.1. XT4302, XT430L2

- 1.4.4.2. XT450L2

- 1.4.4.3. Fuel Quality Requirements

- 1.4.4.4. Engine Oil Performance Information

- 1.4.4.5. Hydraulic and Engine Oil Selection, Lubricating Oils and Grease

- 1.4.4.6. New Engine BreakIn Oils

- 1.4.4.7. Hydraulic Oil Information

- 1.4.4.8. General Hydraulic Oil Specification

- 1.4.5. GENERAL INSTRUCTIONS

- 1.4.5.1. Introduction

- 1.4.5.2. Cleaning

- 1.4.5.3. Replacement

- 1.4.5.4. Hoses and Tubes

- 1.4.5.5. Hydraulic Pumps

- 1.4.6. SERVICE AND MAINTENANCE

- 1.4.6.1. Care and Servicing

- 1.4.6.2. Maintenance Safety

- 1.4.6.3. General

- 1.4.6.4. Daily or 10 Hour Interval Maintenance Procedures

- 1.4.6.5. Hour Interval Maintenance Procedures

- 1.4.6.6. Hour Interval Maintenance Procedures

- 1.4.6.7. Hour Interval Maintenance Procedures

- 1.4.6.8. Hour Interval Maintenance Procedures

- 1.4.6.9. ,000 Hour Interval Maintenance Procedures

- 1.4.6.10. ,000 Hour Interval Maintenance Procedures

- 1.4.6.11. Transporting the Machine

- 1.5. SPECIFICATIONS

- 1.5.1. XT4302, XT430L2 Undercarriage

- 1.5.2. XT450L2 Undercarriage

- 1.5.3. Upper Structure

- 1.5.4. Cylinders

- 1.5.5. ELECTRICAL CENTER

- 1.5.6. XT4302 AND XT430L2 SPECIFICATION

- 1.5.7. XT450L2 SPECIFICATIONS

- 1.5.8. BOOM SWEEP DIAGRAMS

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF