Komatsu PC1800-6 Hydraulic Excavator Operation and Maintenance Manual SEAM022902

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM022902

- Format: PDF

- Size: 13.6MB

- Number of Pages: 248

-

Model List:

- PC1800-6 Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER PAGE

- 3. FOREWORD

- 4. SAFETY INFORMATION

- 5. INTRODUCTION

- 6. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 7. CONTENTS

- 8. SAFETY

- 8.1. GENERAL PRECAUTIONS

- 8.2. PRECAUTIONS DURING OPERATION

- 8.2.1. BEFORE STARTING ENGINE

- 8.2.2. AFTER STARTING ENGINE

- 8.2.3. TRANSPORTATION

- 8.2.4. BATTERY

- 8.2.5. TOWING

- 8.2.6. LIFTING OPERATIONS

- 8.3. PRECAUTIONS FOR MAINTENANCE

- 8.3.1. BEFORE CARRYING OUT MAINTENANCE

- 8.3.2. DURING MAINTENANCE

- 8.4. POSITION FOR ATTACHING SAFETY LABELS

- 9. OPERATION

- 9.1. GENERAL VIEW

- 9.1.1. GENERAL VIEW OF MACHINE

- 9.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 9.2. EXPLANATION OF COMPONENTS

- 9.2.1. MACHINE MONITOR

- 9.2.2. SWITCHES

- 9.2.3. LAMP

- 9.2.4. CONTROL LEVERS, PEDALS

- 9.2.5. DOOR LOCK

- 9.2.6. POCKET

- 9.2.7. HANDLING AIR CONDITIONER

- 9.2.8. EMERGENCY ESCAPE HAMMER

- 9.2.9. EMERGENCY ESCAPE LADDER

- 9.2.10. CAP, COVER WITH LOCK

- 9.2.11. ASHTRAY

- 9.2.12. CAR RADIO

- 9.2.13. FUSE

- 9.2.14. CIRCUITBREAKER

- 9.2.15. CONTROLLERS

- 9.2.16. TOOL BOX

- 9.2.17. GREASE PUMP

- 9.2.18. HANDLING GREASE PUMP

- 9.2.19. HANDLING ACCUMULATOR

- 9.2.20. HEALTH MONITOR

- 9.3. OPERATION

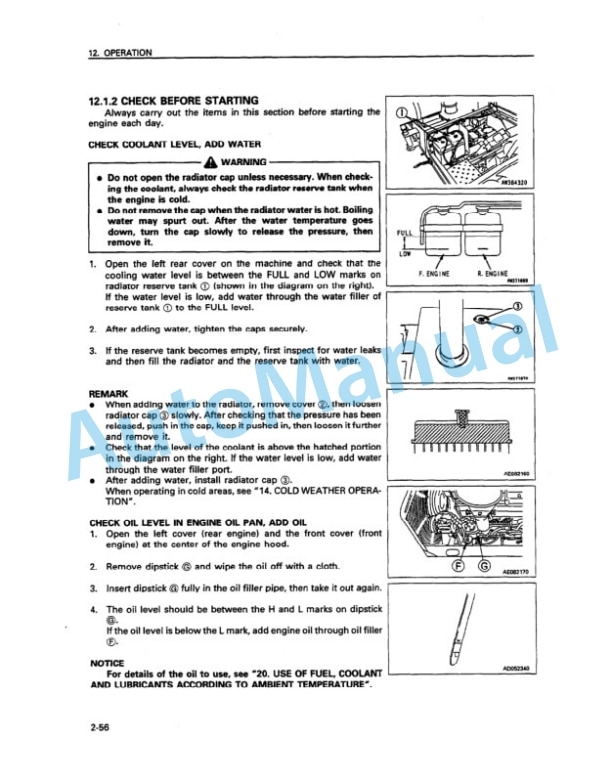

- 9.3.1. CHECK BEFORE STARTING ENGINE

- 9.3.2. STARTING ENGINE

- 9.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 9.3.4. MOVING MACHINE OFF

- 9.3.5. STEERING MACHINE

- 9.3.6. STOPPING MACHINE

- 9.3.7. SWINGING

- 9.3.8. OPERATION OF WORK EQUIPMENT

- 9.3.9. HANDLING WORKING MODE

- 9.3.10. PROHIBITIONS FOR OPERATION

- 9.3.11. PRECAUTIONS FOR OPERATION

- 9.3.12. PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS

- 9.3.13. HOW TO ESCAPE FROM MUD

- 9.3.14. WORK POSSIBLE USING HYDRAULIC EXCAVATOR

- 9.3.15. PHENOMENA THAT ARE NOT FAILURES

- 9.3.16. PARKING MACHINE

- 9.3.17. CHECK AFTER FINISHING WORK

- 9.3.18. STOPPING ENGINE

- 9.3.19. CHECK AFTER STOPPING ENGINE

- 9.3.20. LOCKING

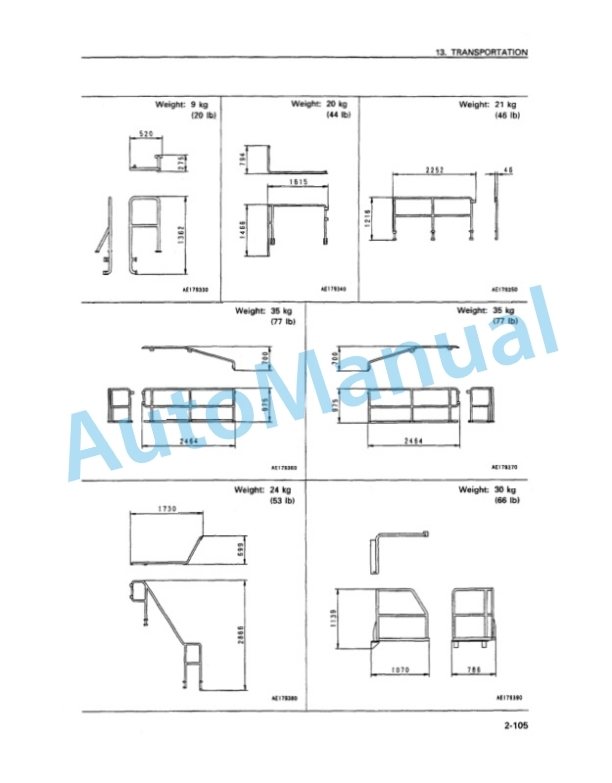

- 9.4. TRANSPORTATION

- 9.4.1. PRECAUTIONS FOR TRANSPORTATION

- 9.4.2. PARTS FOR TRANSPORT

- 9.5. COLD WEATHER OPERATION

- 9.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 9.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 9.5.3. AFTER COLD WEATHER

- 9.6. LONGTERM STORAGE

- 9.6.1. BEFORE STORAGE

- 9.6.2. DURING STORAGE

- 9.6.3. AFTER STORAGE

- 9.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 9.7. TROUBLESHOOTING

- 9.7.1. WHEN FUEL RUNS OUT

- 9.7.2. PHENOMENA THAT ARE NOT FAILURES

- 9.7.3. METHOD OF TOWING MACHINE

- 9.7.4. PRECAUTIONS ON PARTICULAR JOBSITES

- 9.7.5. IF BATTERY IS DISCHARGED

- 9.7.6. OTHER TROUBLE

- 10. MAINTENANCE

- 10.1. GUIDES TO MAINTENANCE

- 10.2. OUTLINES OF SERVICE

- 10.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 10.2.2. OUTLINE OF ELECTRICAL SYSTEM

- 10.2.3. OUTLINE OF HYDRAULIC SYSTEM

- 10.2.4. RELEASING PRESSURE

- 10.2.5. BLEEDING AIR FROM CIRCUIT

- 10.3. CONSUMABLE PARTS LIST

- 10.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 10.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 10.5.1. INTRODUCTION OF NECESSARY TOOLS

- 10.5.2. TORQUE LIST

- 10.6. PERIODIC REPLACEMENT OF CRITICAL SAFETY PARTS

- 10.7. MAINTENANCE SHEDULE CHART

- 10.7.1. MAINTENANCE SCHEDULE CHART

- 10.8. SERVICE PROCEDURE

- 10.8.1. INITIAL 100 HOURS SERVICE (ONLY AFTER THE FIRST 100 HOURS)

- 10.8.1.1. CLEAN STRAINER OF PTO LUBRICATING OIL FILTER

- 10.8.2. INITIAL 250 HOURS SERVICE

- 10.8.2.1. REPLACE FUEL FILTER CARTRIDGE

- 10.8.2.2. CHANGE OIL IN SWING MACHINERY CASE

- 10.8.2.3. CHANGE OIL IN PTO CASE

- 10.8.2.4. CHANGE OIL IN FINAL DRIVE CASE

- 10.8.2.5. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 10.8.3. WHEN REQUIRED

- 10.8.3.1. CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT

- 10.8.3.2. CLEAN INSIDE OF COOLING SYSTEM

- 10.8.3.3. CHECK AND TIGHTEN TRACK SHOE BOLTS

- 10.8.3.4. CHECK AND ADJUST TRACK TENSION

- 10.8.3.5. CHECK ELECTRICAL INTAKE AIR HEATER

- 10.8.3.6. REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE) (KOMATSU TOOTH)

- 10.8.3.7. ADJUST BUCKET CLEARANCE

- 10.8.3.8. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 10.8.3.9. CHECK AND ADJUST AIR CONDITIONER

- 10.8.3.10. CLEANING, REMOVING DIRT FROM LINE FILTER

- 10.8.3.11. REPLACEMENT OF FAN BELT AND ADJUSTMENT OF AUTO TENSIONER

- 10.8.4. CHECK BEFORE STARTING

- 10.8.4.1. CHECK COOLANT LEVEL, ADD WATER

- 10.8.4.2. CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL

- 10.8.4.3. CHECK FUEL LEVEL

- 10.8.4.4. CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

- 10.8.4.5. CHECK FOR CLOGGING OF AIR CLEANER

- 10.8.4.6. CHECK ELECTRICAL WIRING

- 10.8.4.7. CHECK FUNCTION OF HORN

- 10.8.4.8. CHECK OIL LEVEL IN PTO CASE, ADD OIL

- 10.8.4.9. DRAIN WATER, SEDIMENT FROM FUEL TANK

- 10.8.4.10. CHECK CENTRAL MONITOR

- 10.8.5. EVERY 10 HOURS SERVICE

- 10.8.5.1. LUBRICATING

- 10.8.5.2. ARMBUCKET COUPLING PIN (2 POINTS)

- 10.8.5.3. ARMLINK COUPLING PIN (2 POINTS)

- 10.8.5.4. BUCKET CYLINDER ROD END PIN (2 POINTS)

- 10.8.5.5. LINK COUPLING PIN (4 POINTS)

- 10.8.5.6. BUCKETLINK COUPLING PIN (2 POINTS)

- 10.8.5.7. BOOM CYLINDER FOOT PIN

- 10.8.5.8. BOOM FOOT PIN

- 10.8.5.9. BOOM CYLINDER ROD END PIN

- 10.8.5.10. ARM CYLINDER FOOT PIN

- 10.8.5.11. BUCKET CYLINDER FOOT PIN

- 10.8.5.12. BOOMARM COUPLING PIN

- 10.8.5.13. ARMLINK COUPLING PIN

- 10.8.5.14. SWING CIRCLE

- 10.8.6. EVERY 100 HOURS SERVICE

- 10.8.6.1. CHECK OIL LEVEL IN SWING MACHINERY CASE

- 10.8.7. EVERY 250 HOURS SERVICE

- 10.8.7.1. LUBRICATING

- 10.8.7.1.1. FAN PULLEY ASSEMBLY (2 POINTS)

- 10.8.7.1.2. TENSION AND PULLEY ASSEMBLY (2 POINTS)

- 10.8.7.2. CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL

- 10.8.7.3. CHANGE DRAIN FILTER CARTRIDGE

- 10.8.7.4. CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE AND BYPASS FILTER CARTRIDGE (FRONT AND REAR ENGINE)

- 10.8.7.5. CHECK ALTERNATOR DRIVE BELT TENSION ADJUST

- 10.8.7.6. CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST (ONLY FOR MACHINES EQUIPPED WITH AIR CONDITONER)

- 10.8.7.7. CHECK LEVEL OF BATTERY ELECTROLYTE

- 10.8.7.8. CHECK, CLEAN FUEL STRAINER

- 10.8.7.9. CHECK AND TIGHTEN TRACK SHOE BOLTS

- 10.8.7.10. CHECK AND TIGHTEN TRACK FRAME AND AXLE CONNECTING BOLTS

- 10.8.7.11. REPLACE FILTER ELEMENT OF HYDRAULIC TANK BREATHER

- 10.8.8. EVERY 500 HOURS SERVICE

- 10.8.8.1. CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS, AFTER COOLER FINS, CONDENSER FINS (ONLY FOR MACHINES EQUIPPED WITH AIR COND

- 10.8.8.2. CLEAN PILOT FILTER STRAINER

- 10.8.8.3. CLEAN STRAINER OF PTO LUBRICATING OIL FILTER

- 10.8.8.4. REPLACE FUEL FILTER CARTRIDGE

- 10.8.8.5. CLEAN FRESH/RECIRC AIR FILTERS OF AIR CONDITIONER (ONLY FOR MACHINES EQUIPPED WITH AIR CONDITIONER)

- 10.8.8.6. CHECK FAN BELT

- 10.8.8.7. CHANGE HYDRAULIC FILTER ELEMENT

- 10.8.9. EVERY 1000 HOURS SERVICE

- 10.8.9.1. CHANGE OIL IN SWING MACHINERY CASE

- 10.8.9.2. CHECK TURBOCHARGER CLAMPING JOINT

- 10.8.9.3. CHANGE OIL IN PTO CASE

- 10.8.9.4. REPLACE CORROSION RESISTOR CARTRIDGE

- 10.8.9.5. CHECK INSPECTION OF WELDING STRUCTURE (COLOR CHECK)

- 10.8.10. EVERY 2000 HOURS SERVICE

- 10.8.10.1. CHANGE OIL IN FINAL DRIVE CASE

- 10.8.10.2. CLEAN, CHECK TURBOCHARGER

- 10.8.10.3. CHECK TURBOCHARGER ROTOR PLAY

- 10.8.10.4. CHECK SWING PINION GREASE LEVEL, ADD GREASE

- 10.8.10.5. CLEAN ENGINE BREATHER

- 10.8.10.6. CLEAN HYDRAULIC TANK STRAINER

- 10.8.10.7. CHECK ALTERNATOR, STARTING MOTOR

- 10.8.10.8. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 10.8.11. EVERY 4000 HOURS SERVICE

- 10.8.11.1. CHECK WATER PUMP

- 10.8.11.2. CHECK VIBRATION DAMPER

- 10.8.11.3. CHECK FAN PULLEY AND TENSION PULLEY

- 10.8.11.4. CHECK AIR COMPRESSOR, ADJUST

- 10.8.12. EVERY 5000 HOURS SERVICE

- 10.8.12.1. CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER

- 11. SPECIFICATIONS

- 11.1. SPECIFICATIONS

- 12. OPTIONS, ATTACHMENTS

- 12.1. GENERAL PRECAUTIONS

- 12.1.1. PRECAUTIONS RELATED TO SAFETY

- 12.1.2. PRECAUTIONS WHEN INSTALLING ATTACHMENTS

- 12.2. INTRODUCTION OF ATTACHMENTS

- 12.2.1. GUARD

- 12.3. AUTOGREASER SYSTEM

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001