Komatsu PC5500-11 Hydraulic Mining Excavator Operation and Maintenance Manual 15191-D-EN-T2-P2-1.0

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 15191-D-EN-T2-P2-1.0

- Format: PDF

- Size: 33.6MB

- Number of Pages: 1055

-

Model List:

- PC5500-11 Hydraulic Mining Excavator

- 1. Front cover PC5500 15191 GB

- 2. TOC GB Vol 2 PC5500 15191

- 3. _03_2_PC5500 spec sheet

- 4. _01_1 Operators seat

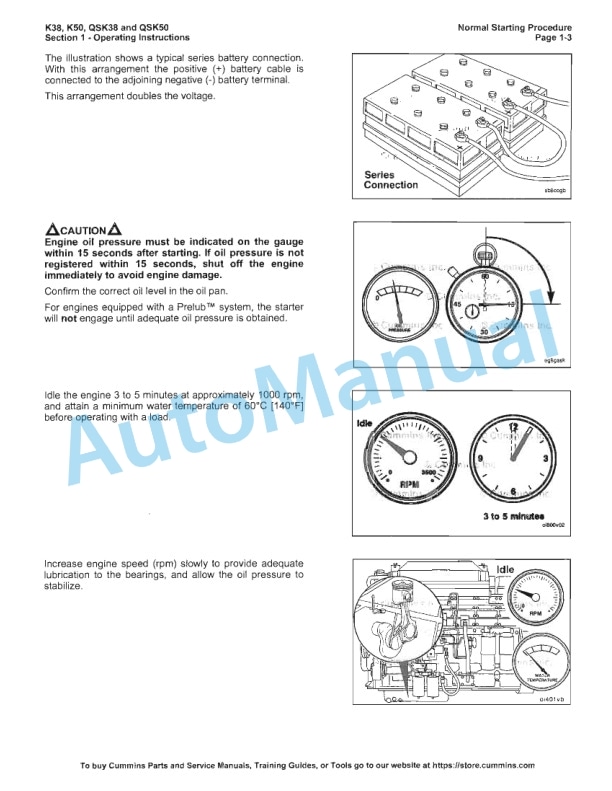

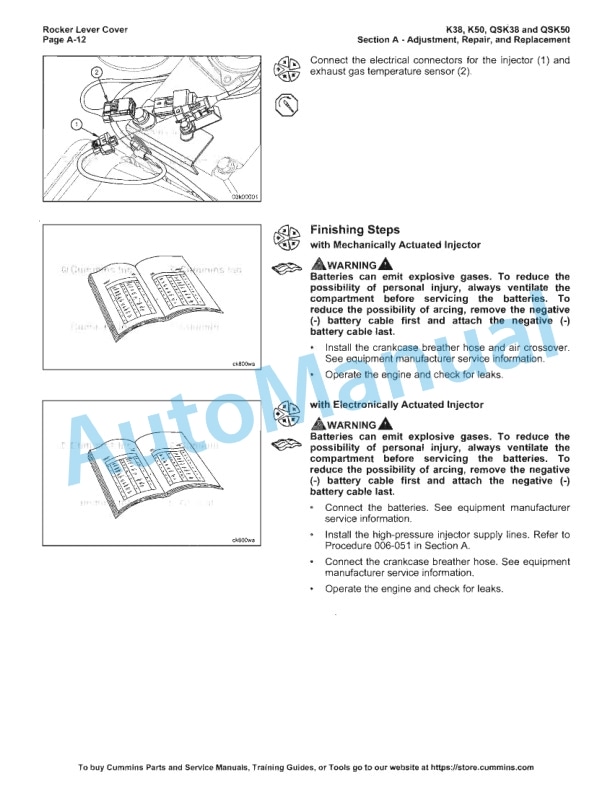

- 5. _01_3 Engine QSK38_QSK50kl

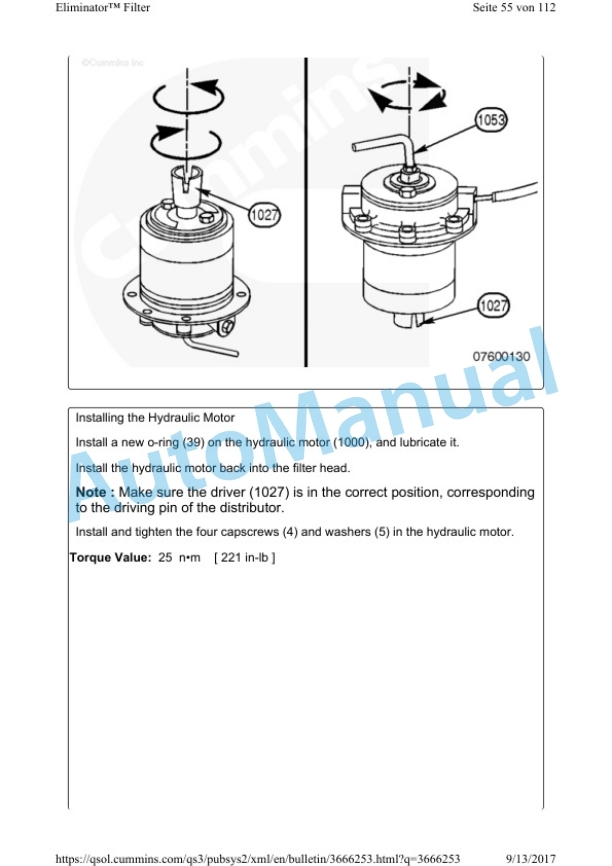

- 6. _01_2_Eliminator filter

- 7. _01_0_Mesabi_Radiator cores

- 8. _04_1_Air con Konvekta GB

- 9. _01_0_Air con Compressor TM Series Service Manual

- 9.1. Safety Precautions

- 9.1.1. Safety Definitions

- 9.1.2. General Safety

- 9.1.3. Refrigerant

- 9.1.4. Refrigerant Oil

- 9.1.5. Leak Detection

- 9.1.6. R134a Applications

- 9.1.7. Compressor Identification Label

- 9.2. Introduction

- 9.2.1. Swash Plate System

- 9.2.2. Piston Drive System

- 9.2.3. Compressor System Guidelines

- 9.2.4. Suggested Operating Region

- 9.2.5. Clutch Application Guidelines

- 9.3. Compressor Clutch and Fitting Options

- 9.4. Dimensions and Specifications

- 9.4.1. TM08 Ear Mount Dimensions and Specifications

- 9.4.2. TM08 Alternator Mount Dimensions and Specifications

- 9.4.3. TM08 Ear Mount PadType Fittings

- 9.4.4. TM13 Dimensions and Specifications

- 9.4.5. TM15 Dimensions and Specifications

- 9.4.6. TM15 Direct Mount Dimensions and Specifications

- 9.4.7. TM16 Dimensions and Specifications

- 9.4.8. TM21 Dimensions and Specifications

- 9.4.9. TM31HD Dimensions and Specifications

- 9.4.10. TM08 Exploded View

- 9.4.11. TM13, TM15, TM16, TM21 Exploded View

- 9.4.12. TM31 Exploded View

- 9.4.13. Tightening Torques

- 9.5. Compressor Maintenance TM08, TM13, TM15, TM16, TM21

- 9.5.1. Safety

- 9.5.2. Refrigerant Recovery

- 9.5.3. Compressor Handling

- 9.5.4. Compressor Storage

- 9.5.5. Compressor Removal

- 9.5.6. Compressor Installation

- 9.5.7. Leak Testing the Compressor

- 9.5.8. Compressor Oil Procedures

- 9.5.9. Clutch Procedures

- 9.5.10. Shaft Seal Procedures

- 9.5.11. Cylinder Head Procedures

- 9.6. Compressor Maintenance TM31

- 9.6.1. Safety

- 9.6.2. Refrigerant Recovery

- 9.6.3. Compressor Handling

- 9.6.4. Compressor Storage

- 9.6.5. Compressor Removal

- 9.6.6. Compressor Installation

- 9.6.7. Oil Procedures

- 9.6.8. Clutch Procedures

- 9.6.9. Shaft Seal Procedures

- 9.7. Appendix Tools and Kits

- 10. _10_0_Matec Refrigerator CompressorGB

- 11. _02_1 KomVision monitor

- 12. _10_1 KomVision Calibration

- 12.1. FOREWORD

- 12.1.1. BEFORE READING THIS MANUAL

- 12.1.2. MAINTAINING THE komvision SYSTEM

- 12.2. SAFETY

- 12.2.1. General Safety

- 12.3. CALIBRATION SHEETS

- 12.3.1. EQUIPMENT

- 12.4. DISPLAY OPERATION

- 12.4.1. ENTERING THE CALIBRATION MENU

- 12.5. CALIBRATION PROCEDURES

- 12.5.1. AUTOMATIC CALIBRATION

- 12.5.2. MANUAL CALIBRATION

- 12.5.3. MANUAL CALIBRATION WITHOUT SHEETS

- 13. _01_1a_stiebel pto gears maintenance

- 13.1. ServiceManual 4626 01

- 13.2. A4626.01

- 13.3. E4626.01

- 13.4. Ersatzteilliste_DE_4626.01

- 13.5. Ersatzteilliste_GB_4626.01

- 14. _04_0 Centa coupling Diesel

- 14.1. General remarks

- 14.2. Safety

- 14.2.1. Safety remarks

- 14.2.2. Qualification of deployed personnel

- 14.2.3. Intended application

- 14.2.4. Application not in compliance with the intended use

- 14.3. Delivery, transport, storage and disposal

- 14.3.1. Delivery

- 14.3.2. Transport

- 14.3.3. Storage

- 14.3.4. Disposal

- 14.4. Characteristics

- 14.5. Mounting

- 14.5.1. General assembly instructions

- 14.5.2. Mounting the outer part

- 14.5.3. Placing the inner part assembly in the installation space

- 14.5.4. Position the sheet on the adapter

- 14.5.5. Mounting the adapter to the customer part

- 14.5.6. Mounting the adapter to the inner part assembly

- 14.5.7. Install the rubber elements

- 14.5.8. Mounting the sheet

- 14.5.9. After completed mounting

- 14.6. Operation

- 14.6.1. Operating faults, root causes and remedy

- 14.7. Care and maintenance

- 14.7.1. Maintenance intervals

- 14.7.2. Work to be performed

- 14.7.3. Replacing defective parts

- 14.8. Dismantling

- 14.8.1. General dismantling instructions

- 14.8.2. Dismantling the coupling

- 14.8.3. Dismantling the coupling for replacing the wearing parts

- 14.9. Wearing and spare parts

- 14.10. Annex

- 14.10.1. CENTA data sheet D013016 (unlubricated screw connections)

- 14.10.2. CENTA data sheet D013017 (SAE flywheel screw connection)

- 14.10.3. CENTA data sheet D026900 Declaration of incorporation according to the EC Machinery Directive 2006/42/EC, Appendix II B

- 15. _14_1_Lubrication Specifications

- 15.1. FOREWORD

- 15.1.1. KOMATSU GERMANY (MINING) LUBRICATION INFORMATION SPECIFICATIONS

- 15.1.2. General SAFETY

- 15.2. INTRODUCTION

- 15.2.1. GENERAL INFORMATION TO LUBRICANTS

- 15.3. HYDRAULIC OILS

- 15.3.1. INTRODUCTION TO HYDRAULIC OILS

- 15.3.2. WHAT IS HYDRAULIC OIL

- 15.3.3. ANALYSING HYDRAULIC OILS

- 15.3.4. KOMATSU GERMANY (MINING) RECOMMENDATIONS

- 15.4. GEAR OILS

- 15.4.1. Introduction to Gear Oils

- 15.4.2. ANALYSING GEAR OILS

- 15.4.3. KOMATSU GERMANY (MINING) RECOMMENDATIONS

- 15.5. ENGINE OILS

- 15.5.1. Introduction to ENGINE Oils

- 15.6. GREASES, INTRODUCTION

- 15.6.1. GREASES

- 15.7. GREASE FOR THE CLS

- 15.7.1. KOMATSU GERMANY (MINING) RECOMMENDATIONS

- 15.8. GREASE FOR THE SLS

- 15.8.1. KOMATSU GERMANY (MINING) RECOMMENDATIONS

- 15.9. GREASE FOR ROLLERS

- 15.9.1. KOMATSU GERMANY (MINING) RECOMMENDATIONS

- 15.10. OTHER FLUIDS

- 15.10.1. Coolant

- 15.10.2. Grease for electric motors BEARINGS

- 15.10.3. AIR CONDITIONER

- 15.11. SIMPLIFIED RECOMMENDATION PROCEDURES

- 16. _09_0 DIS PC5500BHADGB

- 16.1. Daily Check Sheet for Backhoe Attachment

- 16.2. Daily Check Sheet for Track Groups and Center Frames

- 16.3. Daily Check Sheet for Ladders and Engine Area

- 16.4. Daily Check Sheet for Main Pump Area

- 16.5. Daily Check Sheet for Superstructure (Hydraulics)

- 16.6. Daily Check Sheet for Superstructure (Cab Base Upper Deck)

- 16.7. Daily Check Sheet for Hoses on Attachment Oil Reservoir

- 17. Blank Page

- 18. Blank Page

- 19. Blank Page

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745