- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WD600-1H Wheel Dozer Operation and Maintenance Manual SEAMW01900

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAMW01900

- Format: PDF

- Size: 20.5MB

- Number of Pages: 209

-

Model List:

- WD600-1H Wheel Dozer

- 1. MAIN MENU

- 2. COVER

- 3. FOREWARD

- 4. SAFETY INFORMATION

- 5. INTRODUCTION

- 5.1. INTENDED USE

- 5.2. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 5.3. BREAKING IN THE MACHINE

- 6. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 6.1. MACHINE SERIAL NO. PLATE POSITION

- 6.2. ENGINE SERIAL NO. PLATE POSITION

- 6.3. POSITION OF SERVICE METER

- 6.4. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 7. CONTENTS

- 8. SAFETY

- 8.1. GENERAL PRECAUTIONS

- 8.2. PRECAUTIONS FOR OPERATION

- 8.2.1. BEFORE STARTING ENGINE

- 8.2.2. AFTER STARTING ENGINE

- 8.2.3. TRANSPORTATION

- 8.2.4. BATTERY

- 8.2.5. TOWING

- 8.3. PRECAUTIONS FOR MAINTENANCE

- 8.3.1. BEFORE CARRYING OUT MAINTENANCE

- 8.3.2. DURING MAINTENANCE

- 8.3.3. PRECAUTIONS WITH TIRES

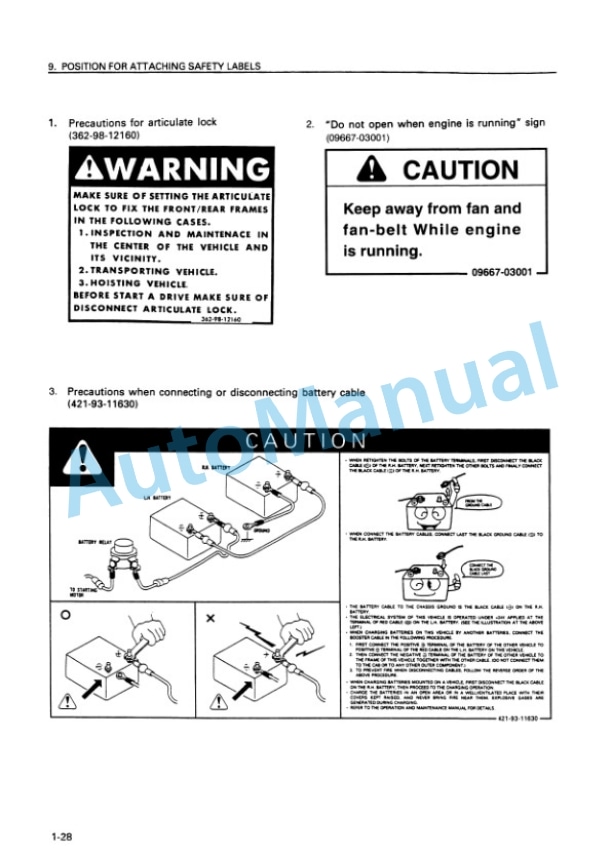

- 8.4. POSITION FOR ATTACHING SAFETY LABELS

- 8.4.1. POSITION FOR ATTACHING SAFETY LABELS

- 9. OPERATION

- 9.1. GENERAL VIEW

- 9.1.1. GENERAL VIEW OF MACHINE

- 9.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 9.2. EXPLANATION OF COMPONENTS

- 9.2.1. METERS AND LAMPS

- 9.2.2. SWITCHES

- 9.2.3. CONTROL LEVERS, PEDALS

- 9.2.4. STEERING COLUMN TILT LEVER

- 9.2.5. DUST INDICATOR

- 9.2.6. CAP WITH LOCK

- 9.2.7. SAFETY BAR

- 9.2.8. TOWING PIN

- 9.2.9. BACKUP ALARM

- 9.2.10. CIRCUIT BREAKER

- 9.2.11. CIRCUIT BREAKER (MAIN)

- 9.2.12. AIR CONDITIONER

- 9.3. OPERATION

- 9.3.1. CHECK BEFORE STARTING ENGINE

- 9.3.2. STARTING ENGINE

- 9.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 9.3.4. MOVING MACHINE OFF

- 9.3.5. CHANGING GEAR SPEED

- 9.3.6. CHANGING DIRECTION

- 9.3.7. TURNING

- 9.3.8. STOPPING MACHINE

- 9.3.9. OPERATION OF WORK EQUIPMENT

- 9.3.10. WORK POSSIBLE USING WHEEL DOZER

- 9.3.11. PRECAUTIONS FOR OPERATION

- 9.3.12. PARKING MACHINE

- 9.3.13. CHECKS AFTER COMPLETION OF OPERATION

- 9.3.14. STOPPING ENGINE

- 9.3.15. CHECK AFTER STOPPING ENGINE

- 9.3.16. LOCKING

- 9.3.17. HANDLING TIRES

- 9.4. TRANSPORTATION

- 9.4.1. LOADING, UNLOADING WORK

- 9.4.2. PRECAUTIONS FOR LOADING

- 9.4.3. LIFTING MACHINE

- 9.4.4. PRECAUTIONS FOR TRANSPORTATION

- 9.5. COLD WEATHER OPERATION

- 9.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 9.5.2. HANDLING ENGINE PANEL COVER, AIR CLEANER SUCTION PORT PANEL

- 9.5.3. HANDLING RADIATOR SHUTTER

- 9.5.4. HANDLING BRAKE OIL

- 9.5.5. PRECAUTIONS AFTER COMPLETION OF WORK

- 9.5.6. AFTER COLD WEATHER

- 9.5.7. WARMING UP OPERATION

- 9.6. LONG TERM STORAGE

- 9.6.1. BEFORE STORAGE

- 9.6.2. DURING STORAGE

- 9.6.3. AFTER STORAGE

- 9.7. TROUBLESHOOTING

- 9.7.1. WHEN MACHINE RUNS OUT OF FUEL

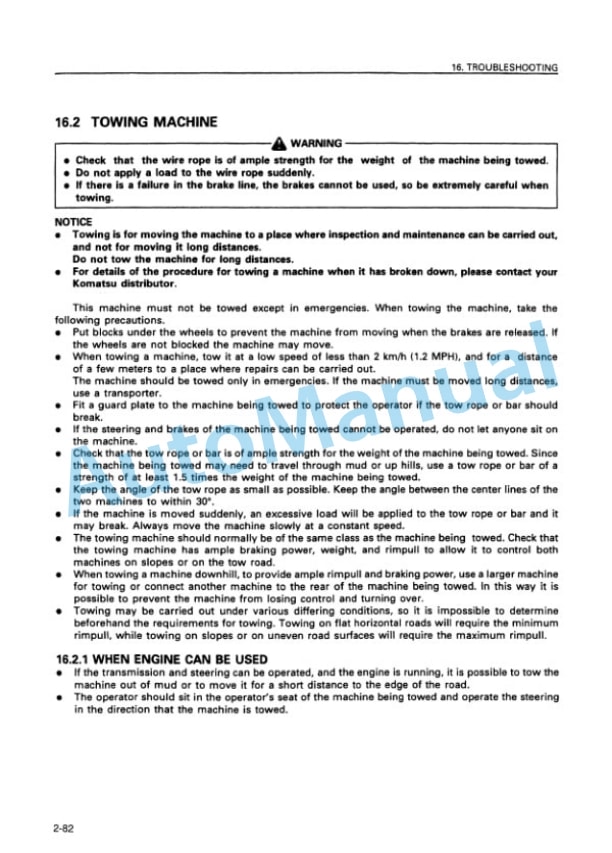

- 9.7.2. TOWING MACHINE

- 9.7.3. IF BATTERY IS DISCHARGED

- 9.7.4. OTHER TROUBLE

- 10. MAINTENANCE

- 10.1. GUIDES TO MAINTENANCE

- 10.2. OUTLINES OF SERVICE

- 10.2.1. OUTLINE OF OIL, FUEL, AND COOLANT

- 10.2.2. OUTLINE OF ELECTRIC SYSTEM

- 10.3. WEAR PARTS LIST

- 10.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 10.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 10.5.1. TORQUE LIST

- 10.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 10.7. MAINTENANCE SCHEDULE CHART

- 10.7.1. MAINTENANCE SCHEDULE CHART

- 10.8. SERVICE PROCEDURE

- 10.8.1. INITIAL 250 HOURS SERVICE

- 10.8.1.1. REPLACE FUEL FILTER CARTRIDGE

- 10.8.1.2. REPLACE TRANSMISSION OIL FILTER ELEMENT

- 10.8.1.3. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 10.8.2. WHEN REQUIRED

- 10.8.2.1. CHECK, CLEAN, OR REPLACE AIR CLEANER ELEMENT

- 10.8.2.2. CLEAN INSIDE OF COOLING SYSTEM

- 10.8.2.3. CHECK TRANSMISSION OIL LEVEL, ADD OIL

- 10.8.2.4. CHECK AXLE OIL LEVEL, ADD OIL

- 10.8.2.5. CHECK AXLE CASE BREATHER

- 10.8.2.6. CLEAN CONDENSER OF AIR CONDITIONER

- 10.8.2.7. CLEAN RADIATOR FINS

- 10.8.2.8. CHECK APS (AUTOMATIC PRIMING SYSTEM)

- 10.8.2.9. REPLACING END BIT AND CUTTING EDGE

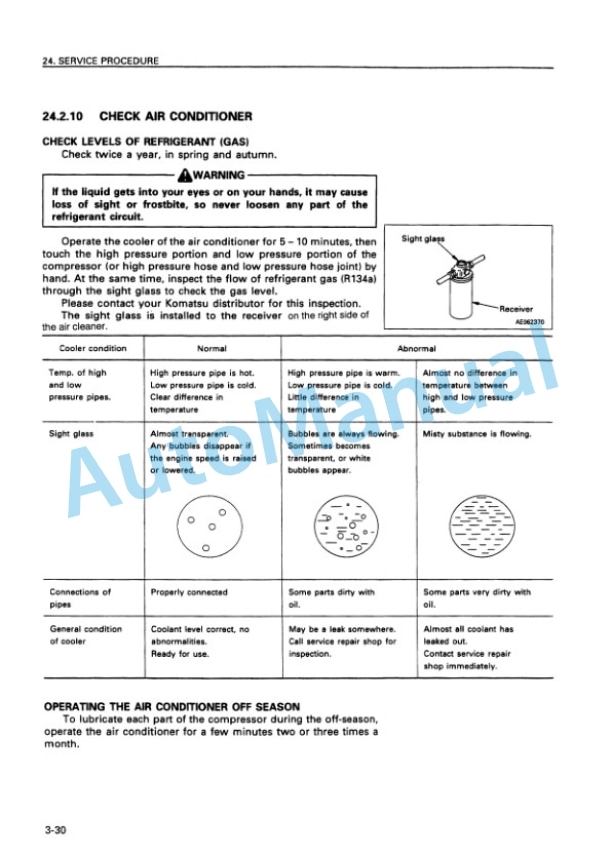

- 10.8.2.10. CHECK AIR CONDITIONER

- 10.8.2.11. CHECK WINDOW WASHING FLUID LEVEL, ADD FLUID

- 10.8.2.12. SELECTION AND INSPECTION OF TIRES

- 10.8.2.13. LUBRICATING

- 10.8.2.13.1. WORK EQUIPMENT CONTROL VALVE LINKAGE (5 POINTS)

- 10.8.2.13.2. ACCELERATION PEDAL LINKAGE (2 POINTS)

- 10.8.2.13.3. STEERING COLUMN (1 POINT)

- 10.8.2.14. REPLACE RUBBER PARTS (SEALS) OF BRAKE CHAMBER

- 10.8.2.15. BLEEDING AIR FROM BRAKE HYDRAULIC CIRCUIT

- 10.8.2.16. ADJUST PARKING BRAKE

- 10.8.3. CHECK BEFORE STARTING

- 10.8.4. EVERY 50 HOURS MAINTENANCE

- 10.8.4.1. DRAIN WATER, SEDIMENT FROM FUEL TANK

- 10.8.5. EVERY 100 HOURS SERVICE

- 10.8.5.1. CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

- 10.8.5.2. CLEAN AIR CONDITIONER AIR FILTER ELEMENT

- 10.8.5.3. LUBRICATE REAR AXLE PIVOT PIN (3 POINTS)

- 10.8.6. EVERY 250 HOURS SERVICE

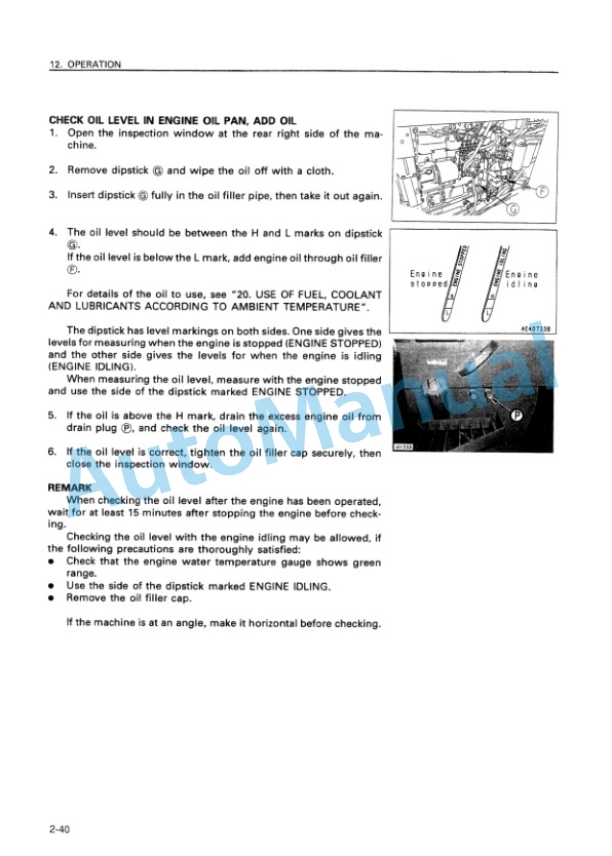

- 10.8.6.1. CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE

- 10.8.6.2. CHECK BATTERY ELECTROLYTE LEVEL

- 10.8.6.3. CHECK ALTERNATOR BELT TENSION, ADJUST

- 10.8.6.4. CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST

- 10.8.6.5. CHECK FOR LOOSE WHEEL HUB NUTS, TIGHTEN

- 10.8.6.6. LUBRICATING

- 10.8.6.6.1. LIFT CYLINDER PIN (2 POINTS)

- 10.8.6.6.2. LINK PIN (5 POINTS)

- 10.8.6.6.3. STEERING CYLINDER BOTTOM PIN (2 POINTS)

- 10.8.6.6.4. STEERING CYLINDER ROD END (2 POINTS)

- 10.8.6.6.5. TRANSMISSION MOUNT TRUNION (1 POINT)

- 10.8.7. EVERY 500 HOURS SERVICE

- 10.8.7.1. REPLACE FUEL FILTER CARTRIDGE

- 10.8.7.2. REPLACE TRANSMISSION OIL FILTER ELEMENT

- 10.8.7.3. LUBRICATING

- 10.8.7.3.1. CENTER DRIVE SHAFT SPLINE (1 POINT)

- 10.8.7.3.2. FAN PULLEY (1 POINT)

- 10.8.7.3.3. TENSION PULLEY (2 POINTS)

- 10.8.7.4. CHECK FAN BELT FOR WEAR

- 10.8.8. EVERY 1000 HOURS SERVICE

- 10.8.8.1. CHANGE OIL IN TRANSMISSION CASE, CLEAN STRAINER

- 10.8.8.2. CLEAN TRANSMISSION CASE BREATHER

- 10.8.8.3. LUBRICATING

- 10.8.8.3.1. CENTER HINGE PIN (2 POINTS)

- 10.8.8.3.2. FRONT DRIVE SHAFT (3 POINTS)

- 10.8.8.3.3. DRIVE SHAFT CENTER SUPPORT (1 POINT)

- 10.8.8.3.4. REAR DRIVE SHAFT (2 POINTS)

- 10.8.8.3.5. CENTER DRIVE SHAFT (3 POINTS)

- 10.8.8.3.6. UPPER DRIVE SHAFT (2 POINTS)

- 10.8.8.3.7. PARKING BRAKE LINKAGE (2 POINTS)

- 10.8.8.3.8. TORQUE CONVERTER OUTPUT SHAFT

- 10.8.8.4. CHECK TIGHTENING PARTS OF TURBOCHARGER

- 10.8.8.5. REPLACE CORROSION RESISTOR CARTRIDGE

- 10.8.8.6. CLEAN FUEL STRAINER

- 10.8.9. EVERY 2000 HOURS SERVICE

- 10.8.9.1. CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC FILTER ELEMENT

- 10.8.9.2. REPLACE HYDRAULIC TANK BREATHER ELEMENT

- 10.8.9.3. CHANGE AXLE OIL

- 10.8.9.4. REPLACE AIR CONDITIONER FILTER

- 10.8.9.5. CLEAN ENGINE BREATHER ELEMENT

- 10.8.9.6. CHECK ALTERNATOR, STARTING MOTOR

- 10.8.9.7. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 10.8.9.8. CHECK BRAKE DISC WEAR

- 10.8.9.9. CLEAN AND CHECK TURBOCHARGER

- 10.8.9.10. CLEAN AIR DRYER ELEMENT

- 10.8.10. EVERY 4000 HOURS SERVICE

- 10.8.10.1. CHECK WATER PUMP

- 10.8.10.2. CHECK FAN PULLEY AND TENSION PULLEY

- 10.8.10.3. CHECK ENGINE VIBRATION DAMPER

- 11. SPECIFICATIONS

- 11.1. SPECIFICATIONS

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF