Table of Content:

1 COVER

2 WARRANTY

3 TABLE OF CONTENTS

4 WARRANTY CLAIMS PROCEDURE

4.1 CLAIMS PROCESS FOR WARRANTED VANAIR PARTS

4.2 PROCEDURE

5 SECTION 1: SAFETY

5.1 1.1 GENERAL INFORMATION

5.2 1.2 DANGERS, WARNINGS, CAUTIONS, AND NOTES

5.3 1.3 INTERNATIONAL SAFETYSYMBOL

5.4 1.4 ARC WELDING HAZARDS

5.5 1.5 ENGINE HAZARDS

5.6 1.6 COMPRESSED AIR HAZARDS

5.7 1.7 HYDRAULIC PUMP HAZARDS

5.8 1.8 ADDITIONAL SYMBOLS FOR INSTALLATION, OPERATION AND MAINTENANCE

5.9 1.9 CALIFORNIA PROPOSITION 65 WARNINGS

5.10 1.10 PRINCIPAL SAFETY STANDARDS

5.11 1.11 EMF INFORMATION

5.12 1.12 MACHINE CANOPY ACCESS SAFETY SWITCHES

5.13 1.13 DISPOSING OF MACHINE FLUIDS

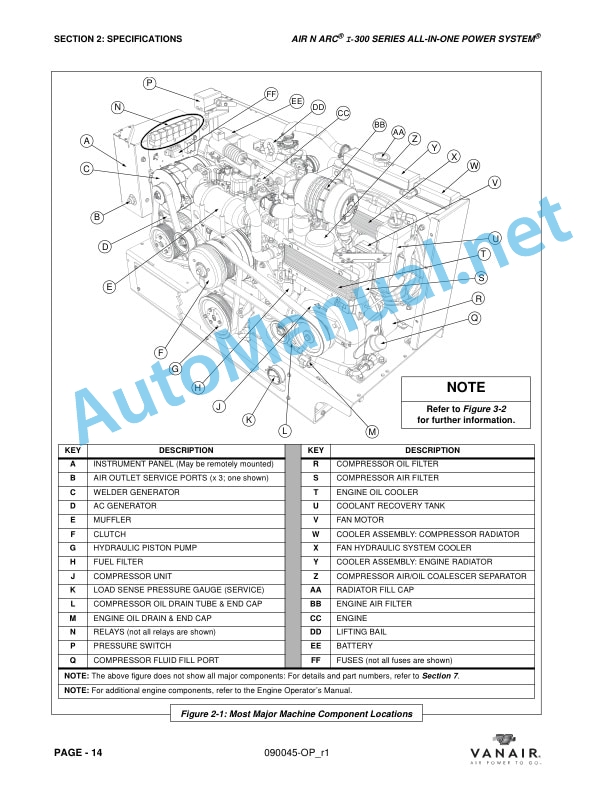

6 SECTION 2: SPECIFICATIONS

6.1 TABLE 2A: ENGINE, HYDRAULIC SYSTEM, WELDER, AND GENERATOR SPECIFICATIONS

6.2 TABLE 2B: AIR COMPRESSOR SPECIFICATIONS

6.3 TABLE 2C: SPECIFICATIONS – ARC I-300 SERIES ALL-IN-ONE POWER SYSTEM MACHINE PACKAGE RECEIPT/INSPECTION

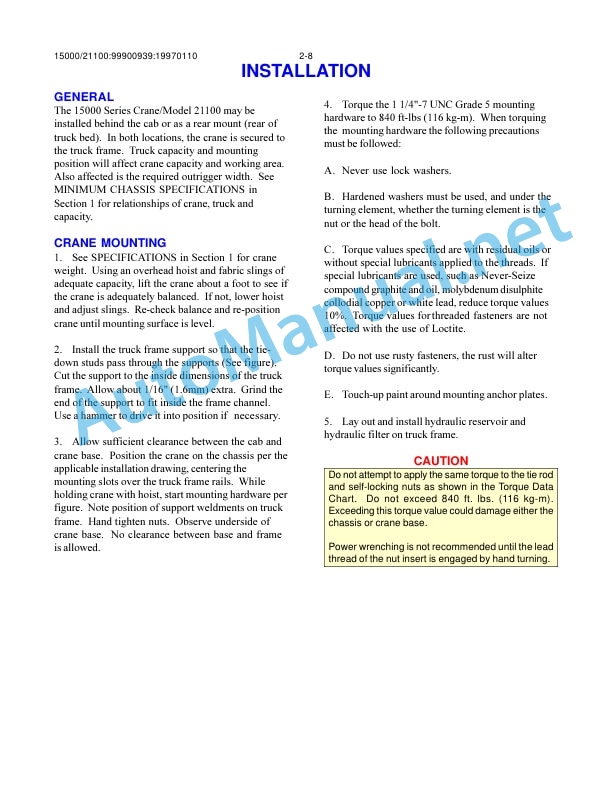

7.2 3.2 GENERAL OVERVIEW OF INSTALLATION

7.3 3.3 MOUNTING THE MACHINE

7.4 3.4 CONNECTING THE FUELSYSTEM

7.5 3.5 CONNECTING AND APPLYING THE HYDRAULIC SYSTEM

7.6 3.6 INSTALLING THE REMOTE CONTROL PANEL

7.7 3.7 INSTALLING (OPTIONAL) REMOTE AIR TANK

7.8 3.8 FUEL LINE SIPHON

8 SECTION 4: OPERATION

8.1 4.1 GENERAL INFORMATION

8.2 4.2 MACHINE START-UP AND SHUTDOWN PROCEDURE

8.3 4.3 ENGINE THROTTLE CONTROL FUNCTIONS

8.4 4.4 OPERATING THE WELDER

8.5 4.5 OPERATING THE GENERATOR

8.6 4.6 OPERATING THE COMPRESSOR

8.7 4.7 OPERATING THE BATTERY BOOSTER/CHARGER

8.8 4.8 USING THE START OVERRIDE SWITCH TO JUMP-START THE VEHICLE

8.9 4.9 OPERATING THE HYDRAULIC PUMP

8.10 4.10 EXTREME CONDITION OPERATION

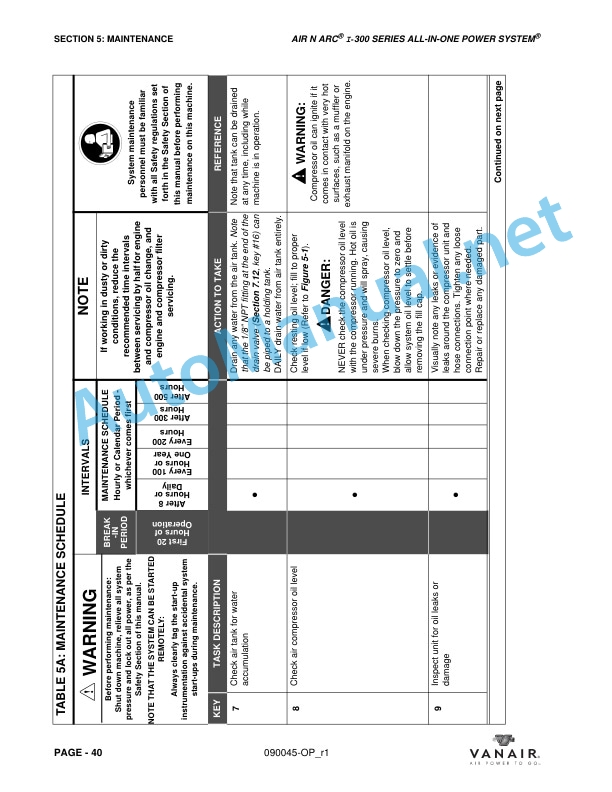

9 SECTION 5: MAINTENANCE

9.1 5.1 GENERAL INFORMATION

9.2 5.2 ROUTINE MAINTENANCE SCHEDULE

9.3 TABLE 5A: MAINTENANCE SCHEDULE

9.4 5.3 REPLACEMENT PARTS

9.5 5.4 PARTS REPLACEMENTAND ADJUSTMENT PROCEDURES

9.6 5.5 STORAGE AND INTERMITTENT USE

10 SECTION 6: TROUBLESHOOTING

10.1 6.2 TROUBLESHOOTING GUIDE

10.2 6.1 GENERAL INFORMATION

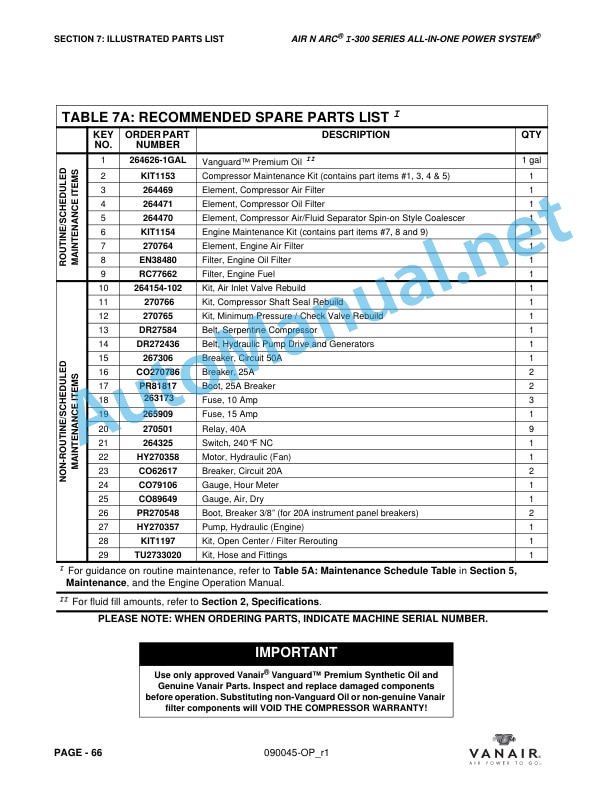

11 SECTION 7: ILLUSTRATED PARTS LIST

11.1 7.1 PARTS ORDERING PROCEDURE

11.2 TABLE 7A: RECOMMENDED SPARE PARTS LIST

11.3 7.2 AIR N ARC I-300 SYSTEMS ASSEMBLIES

11.4 7.3 AIR STORAGE ASSEMBLY

11.5 7.4 COMPRESSOR AND PARTS ASSEMBLY (1 OF 2)

11.6 7.4 COMPRESSOR AND PARTS ASSEMBLY (2 OF 2)

11.7 7.5 COOLING SYSTEM

11.8 7.6 FRAME AND CANOPY ASSEMBLY (1 OF 2)

11.9 7.6 FRAME AND CANOPY ASSEMBLY (2 OF 2)

11.10 7.7 INSTRUMENT PANEL

11.11 7.8 GENERATORS AND PARTS

11.12 7.9 HYDRAULIC PUMP ASSEMBLY (1 OF 3)

11.13 7.9 HYDRAULIC PUMP ASSEMBLY – OPEN CENTER (2 OF 3)

11.14 7.9 HYDRAULIC PUMP ASSEMBLY – CLOSED CENTER (3 OF 3)

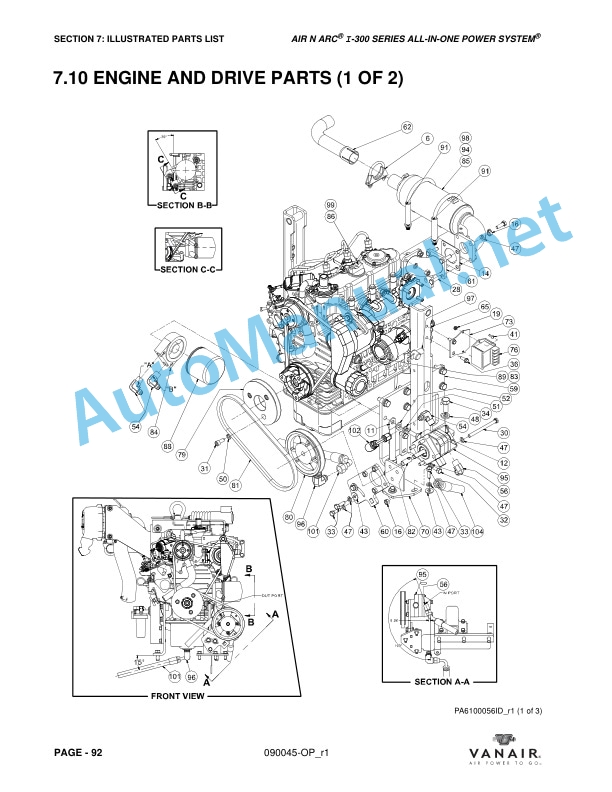

11.15 7.10 ENGINE AND DRIVE PARTS (1 OF 2)

11.16 7.10 ENGINE AND DRIVE PARTS (2 OF 2)

11.17 7.11 ELECTRICAL SYSTEM

11.18 7.12 MANIFOLD ASSEMBLY

11.19 7.13 HYDRAULIC TANK ASSEMBLY

11.20 7.14 DECAL AND PLATE LOCATIONS (1 OF 4)

11.21 7.14 DECAL AND PLATE LOCATIONS (2 OF 4)

11.22 7.14 DECAL AND PLATE LOCATIONS (3 OF 4)

11.23 7.14 DECAL AND PLATE LOCATIONS (4 OF 4)

11.24 7.15 WIRING DIAGRAM – AIR N ARC I-300 SERIES

11.25 7.16 WIRING DIAGRAM – SWITCHES AND LIGHTS

11.26 7.17 SCHEMATIC DIAGRAM – HYDRO CRANE, O.C., NO TOOL

11.27 7.18 SCHEMATIC DIAGRAM – HYDRO C.C. CRANE, NO TOOL

11.28 7.19 SCHEMATIC DIAGRAM – COMPRESSOR FLOW

11.29 7.20 HOSE INSTALLATION GUIDE