Komatsu 860E-1K, 860E-1KT, 960E-1K, 960E-2K, 960E-2KT Machine Intervention System Operation and Maintenance Manual CEAM031801

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM031801

- Format: PDF

- Size: 6.6MB

- Number of Pages: 100

-

Model List:

- 860E-1K Machine Intervention System

- 860E-1KT Machine Intervention System

- 960E-1K Machine Intervention System

- 960E-2K Machine Intervention System

- 960E-2KT Machine Intervention System

- 1. COVER

- 2. LEGAL WAIVER

- 2.1. Limitations of the Machine Intervention System

- 2.2. Braking Intervention

- 2.3. Situations in which the MIS may not operate properly.

- 2.4. MIS warning panel system light turns red

- 3. INTRODUCTION

- 3.1. Forward

- 3.2. Machine Intervention Controller Data Recordings

- 3.3. Data Usage

- 3.4. About this Manual

- 3.5. Alerts Page

- 4. TABLE OF CONTENTS

- 5. MACHINE INTERVENTION CONTROLLER

- 5.1. General Information

- 5.2. Component Description

- 5.3. Intervention Circuits

- 5.4. Override Switch

- 5.5. Indicator Panel

- 5.5.1. Indicator Panel Symbols

- 5.6. System Status

- 5.7. Forward Propel Inhibit

- 5.8. BodyUp Inhibit

- 5.9. Braking Status

- 5.10. Reverse Propel Inhibit

- 5.11. Engine Crank Inhibit

- 5.12. Drowsiness Detection

- 5.12.1. Special Tools

- 5.13. Wiring Harness, Bypass

- 5.14. Cable, CAT5E PLM4

- 5.15. Template, Cab Bottom

- 6. UPDATING THE MIC FIRMWARE

- 6.1. To update the MIC firmware

- 6.1.1. Prepare a USB flash drive

- 6.1.2. Update the firmware

- 7. SYSTEM CONFIGURATION

- 7.1. Connecting to the MIC Web Server

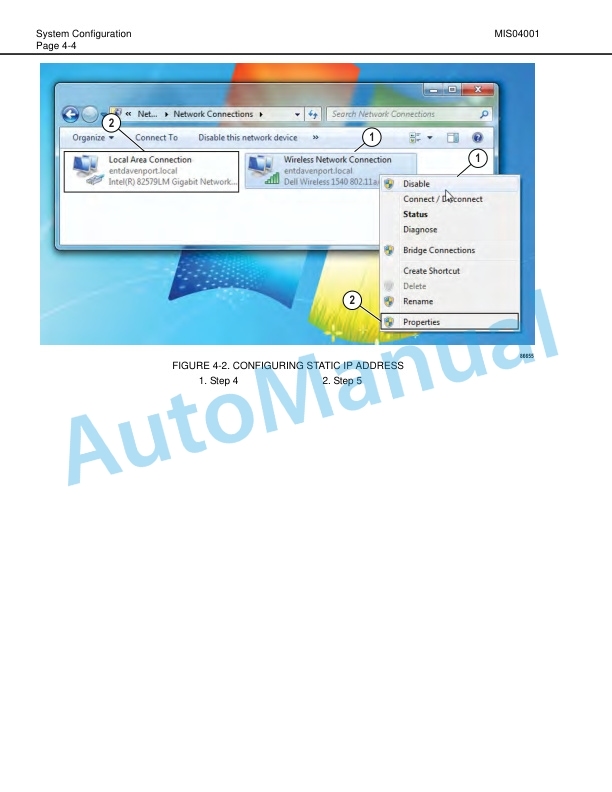

- 7.2. Configuring Static IP Address

- 7.3. Real Time Data

- 7.4. Machine Intervention Controller System Configuration

- 7.5. Retarder Output Calibration

- 7.6. Controller Removal

- 7.6.1. Machine Intervention Controller Intervention Checkout

- 7.7. Available inhibitions are

- 8. TROUBLESHOOTING FAULT CODES

- 8.1. M001 Forward Propel Inhibit Fault

- 8.2. M002 Reverse Propel Inhibit Fault

- 8.3. M003 Hoist Inhibit Fault

- 8.4. M004 Starter Inhibit Fault

- 8.5. M005 Remote Shutdown Fault

- 8.6. M006 Retarder Output Fault

- 8.7. M007 Auto Apply Output Fault

- 8.8. M011 MIC has experienced an unexpected power loss

- 8.9. M012 MIC Loss of Indicator Panel Communication

- 8.10. M058 3rd Party Controller CAS Geofence Radar Fault

- 8.11. M059 3rd Party Controller CAS Geofence GPS Fault

- 8.12. M060 3rd Party Controller CAS Geofence RF Communications Fault

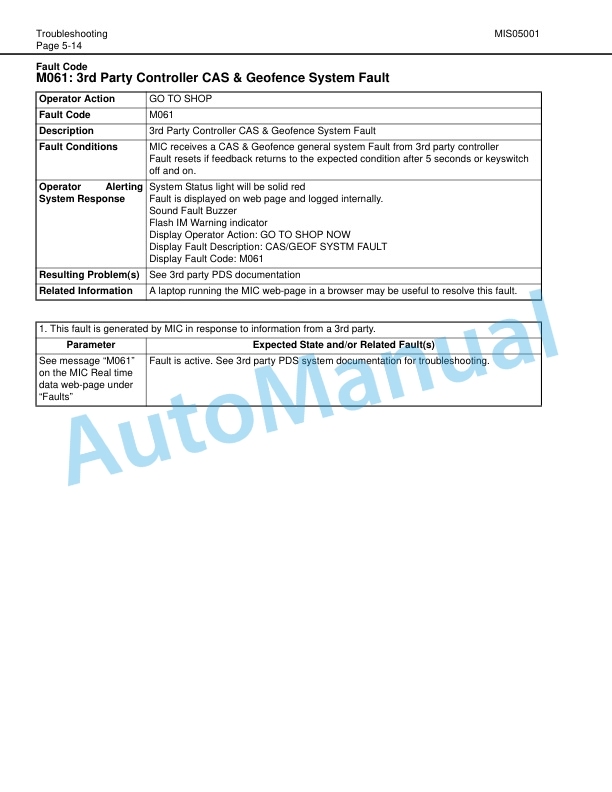

- 8.13. M061 3rd Party Controller CAS Geofence System Fault

- 8.14. M062 Loss of 3rd Party Controller CAS Geofence Communication

- 8.15. M063 3rd Party Controller Take Off Protection Rear Radar Fault

- 8.16. M064 3rd Party Controller Take Off Protection Front Radar Fault

- 8.17. M065 3rd Party Controller Take Off Protection GPS Fault

- 8.18. M066 3rd Party Controller Take Off Protection RF System Fault

- 8.19. M067 3rd Party Controller Take Off Protection System Fault

- 8.20. M068 Loss of 3rd Party Controller Take Off Protection Communication

- 8.21. M069 Loss of 3rd Party Controller Camera Fault

- 8.22. M070 3rd Party Controller Drowsiness Detection System Fault

- 8.23. M071 Loss of 3rd Party Controller Drowsiness Detection System Communication

- 8.24. M072 3rd Party Controller Operator Licensing RF Communication Fault

- 8.25. M073 3rd Party Controller Operator Licensing System Fault

- 8.26. M074 Loss of 3rd Party Controller Operator Licensing System Communication

- 8.27. M078 No Message Received by MIC on Safety Subnet

- 8.28. M079 Override Switch Input on for >180 Seconds

- 8.29. M080 No Message, or Failure to Receive Message, from RPC Bus for >3 Seconds

- 8.30. M088 Loss of 3rd party Takeoff Protection inhibits because 3rd party controller is malfunctioning

- 8.31. M089 Loss of 3rd party CAS Geofenced Restrictions inhibits because 3rd party controller is malfunctioning

- 8.32. M090 Loss of 3rd party Drowsiness Detection warnings because 3rd party controller is malfunctioning

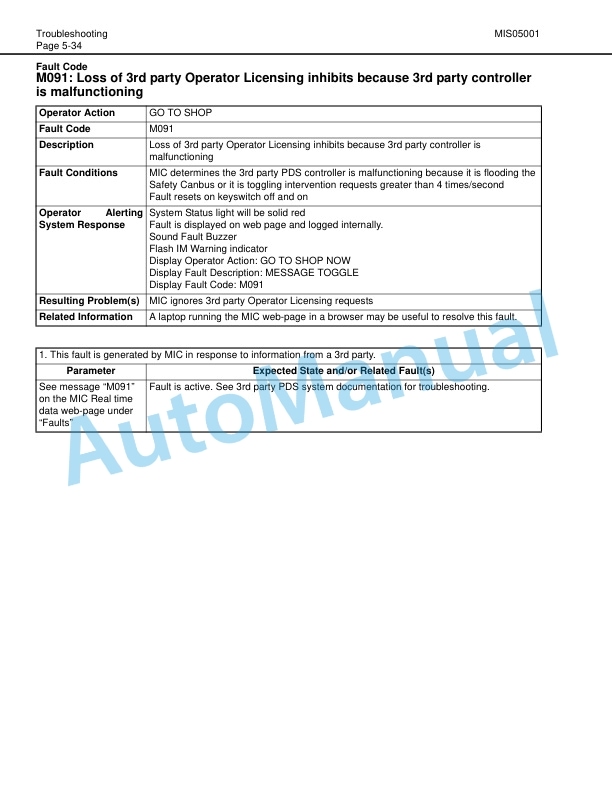

- 8.33. M091 Loss of 3rd party Operator Licensing inhibits because 3rd party controller is malfunctioning

- 8.34. NONE MIC Total Communication Loss

- 8.35. NONE MIC Intervention wont Release

- 9. MACHINE INTERVENTION SYSTEM CHECKOUT PROCEDURE

- 9.1. General Information on System Checkout

- 9.2. Install the Application Code

- 9.3. Required Equipment

- 9.4. Precheckout Items

- 9.4.1. Precheckout Item 1

- 9.4.2. Precheckout Item 2

- 9.4.3. Precheckout Item 3

- 9.4.4. Precheckout Item 4

- 9.4.5. Precheckout Item 5

- 9.4.6. Precheckout Item 6

- 9.4.7. Precheckout Item 7

- 9.4.8. Precheckout Item 8

- 9.4.9. Precheckout Item 9

- 9.4.10. Initial System Setup

- 9.4.11. System Verification

- 9.4.12. Hydraulic System Checkout Procedure Data Sheet

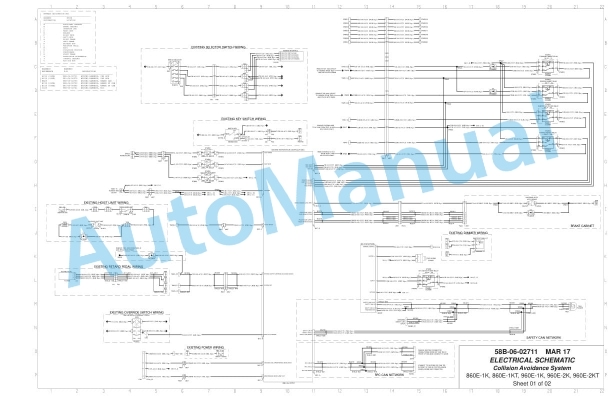

- 10. SYSTEM SCHEMATICS INDEX

- 10.1. Hydraulic Schematic

- 10.2. Electrical Schematic

- 11. PARTS LIST

- 11.1. Component Locations

- 11.2. Cab Controller Installation (1 of 2)

- 11.3. Cab Controller Installation (2 OF 2)

- 11.4. MIC Hydraulic Brake Cabinet Kit (8601KT)

- 11.5. MIC Hydraulic Brake Cabinet Kit (960E)

- 11.6. MIC Controller Wiring (860E1KT)

- 11.7. MIC Controller Wiring (960E)

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615