Komatsu BR350JG-1 Mobile Crusher Operation and Maintenance Manual SEAM020103

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM020103

- Format: PDF

- Size: 14.3MB

- Number of Pages: 280

-

Model List:

- BR350JG-1 Mobile Crusher

- 1. MAIN MENU

- 2. COVER PAGE

- 3. FOREWORD

- 4. SAFETY INFORMATION

- 5. INTRODUCTION

- 6. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 7. CONTENTS

- 8. SAFETY

- 8.1. GENERAL PRECAUTIONS

- 8.2. PRECAUTIONS DURING OPERATION

- 8.2.1. BEFORE STARTING ENGINE

- 8.2.2. WHEN AND AFTER STARTING ENGINE

- 8.2.3. CRUSHER (CRUSHING) OPERATIONS

- 8.2.4. TRANSPORTATION

- 8.2.5. BATTERY

- 8.2.6. TOWING

- 8.3. PRECAUTIONS FOR MAINTENANCE

- 8.3.1. BEFORE CARRYING OUT MAINTENANCE

- 8.3.2. DURING MAINTENANCE

- 8.4. POSITION FOR ATTACHING SAFETY LABELS

- 9. OPERATION

- 9.1. GENERAL VIEW

- 9.1.1. GENERAL VIEW OF MACHINE

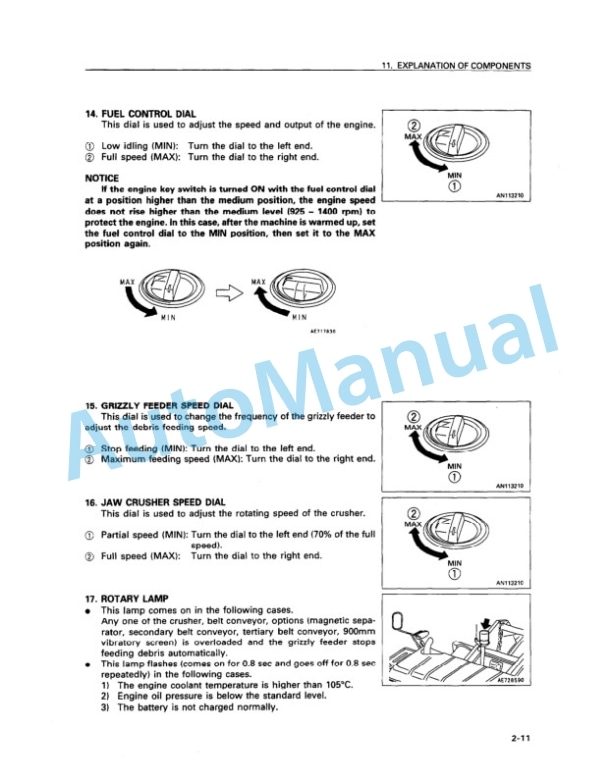

- 9.2. EXPLANATION OF COMPONENTS

- 9.2.1. MACHINE MONITOR

- 9.2.2. SWITCHES

- 9.2.3. CONTROL LEVERS

- 9.2.4. REMOTE CONTROL SWITCHES

- 9.2.5. CAP AND COVER WITH LOCK

- 9.2.6. DUST INDICATOR

- 9.2.7. FUSIBLE LINK

- 9.2.8. FUSES

- 9.2.9. TOOL BOX (SPARE)

- 9.2.10. GREASE GUN HOLDER

- 9.3. OPERATION

- 9.3.1. CHECKS BEFORE STARTING ENGINE

- 9.3.2. STARTING ENGINE

- 9.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 9.3.4. MOVING THE MACHINE OFF

- 9.3.5. STEERING THE MACHINE

- 9.3.6. STOPPING THE MACHINE

- 9.3.7. JAW CRUSHER OPERATIONS

- 9.3.8. WATER SPRINKLER

- 9.3.9. CHECKS AFTER STOPPING JAW CRUSHER OPERATIONS

- 9.3.10. CHECKS AFTER OPERATING

- 9.3.11. STOPPING ENGINE

- 9.3.12. CHECKS AFTER STOPPING ENGINE

- 9.3.13. LOCKING

- 9.3.14. RUNNING IN THE JAW CRUSHER

- 9.3.15. PRECAUTIONS FOR USING JAW CRUSHER

- 9.3.16. EFFICIENT USE OF JAW CRUSHER

- 9.3.17. WORK DONE WITH MOBILE CRUSHER

- 9.3.18. INHIBITED OPERATIONS

- 9.3.19. PRECAUTIONS FOR TRAVELING UP AND DOWN HILLS

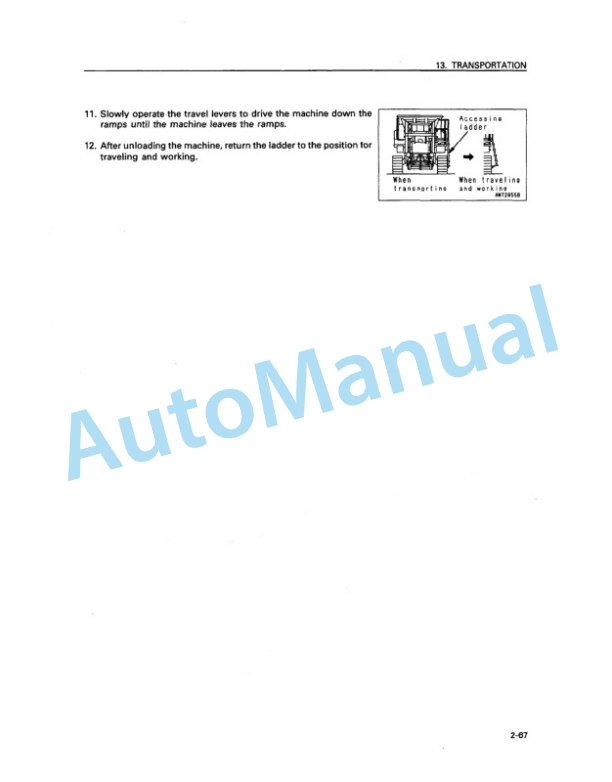

- 9.4. TRANSPORTATION

- 9.4.1. LOADING AND UNLOADING THE MACHINE ON TRAILER

- 9.4.2. FIXING METHOD OF MACHINE

- 9.4.3. PRECAUTIONS FOR LOADING

- 9.4.4. MACHINE LIFTING METHOD

- 9.5. COLD WEATHER OPERATION

- 9.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 9.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 9.5.3. AFTER COLD WEATHER

- 9.6. LONGTERM STORAGE

- 9.6.1. BEFORE STORAGE

- 9.6.2. DURING STORAGE

- 9.6.3. AFTER STORAGE

- 9.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 9.7. TROUBLESHOOTING

- 9.7.1. PHENOMENA THAT ARE NOT FAILURES

- 9.7.2. METHOD OF TOWING MACHINE

- 9.7.3. WHEN A BATTERY IS DISCHARGED

- 9.7.4. TROUBLESHOOTING

- 10. MAINTENANCE

- 10.1. GUIDES TO MAINTENANCE

- 10.2. OUTLINES OF SERVICE

- 10.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 10.2.2. OUTLINE OF ELECTRIC SYSTEM

- 10.2.3. OUTLINE OF HYDRAULIC SYSTEM

- 10.2.4. AIR BLEEDING FROM HYDRAULIC CIRCUIT

- 10.3. OIL FILLER AND OIL LEVEL GAUGE

- 10.3.1. LOCATIONS OF OIL FILLER AND OIL LEVEL GAUGE

- 10.4. WEAR PARTS LIST

- 10.4.1. WEAR PARTS RELATED TO THE BODY

- 10.4.2. WEAR PARTS RELATED TO THE JAW CRUSHER

- 10.4.3. WEAR PARTS RELATED TO THE PRIMARY BELT CONVEYOR

- 10.5. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMERATURE

- 10.6. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 10.6.1. INTRODUCTION OF NECESSARY TOOLS

- 10.6.2. TOOLS ATTACHED TO JAW CRUSHER

- 10.6.3. TORQUE LIST

- 10.7. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 10.8. MAINENANCE SCHEDULE CHART

- 10.8.1. MAINTENANCE SCHEDULE CHART

- 10.9. SERVICE PROCEDURE

- 10.9.1. INITIAL 250 HOURS SERVICE

- 10.9.1.1. REPLACEMENT OF OIL IN ENGINE OIL PAN AND ENGINE OIL FILTER CARTRIDGE

- 10.9.1.2. REPLACEMENT OF FUEL FILTER CARTRIDGE

- 10.9.1.3. REPLACEMENT OF OIL IN GRIZZLY FEEDER VIBRATOR CASE

- 10.9.1.4. CHECK AND ADJUSTMENT OF ENGINE VALVE CLEARANCE

- 10.9.2. WHEN REQUIRED

- 10.9.2.1. CHECK, CLEANING AND REPLACEMENT OF AIR CLEANER

- 10.9.2.2. CLEANING OF INSIDE OF COOLING SYSTEM

- 10.9.2.3. CHECK OF TRACK SHOE BOLT FOR LOOSENESS AND RETIGHTENING

- 10.9.2.4. CHECK AND ADJUSTMENT OF TRACK TENSION

- 10.9.2.5. CHECK AND ADJUSTMENT OF JAW CRUSHER

- 10.9.2.6. CHECK AND ADJUSTMENT OF PRIMARY BELT CONVEYOR

- 10.9.3. CHECK BEFORE STARTING

- 10.9.3.1. CLEANING AND CHECK OF RADIATOR FIN, OIL COOLER FAN AND AFTERCOOLER FAN

- 10.9.3.2. CHECK AND REPLENISHMENT OF COOLING WATER

- 10.9.3.3. CHECK AND REPLENISHMENT OF ENGINE OIL PAN

- 10.9.3.4. CHECK OF FUEL LEVEL

- 10.9.3.5. CHECK AND REPLENISHMENT OF HYDRAULIC OIL

- 10.9.3.6. CHECK OF DUST INDICATOR

- 10.9.3.7. CHECK OF ELECTRIC WIRING

- 10.9.3.8. CHECK OF JAW CRUSHER

- 10.9.3.9. RETIGHTENING OF TOGGLE TENSION BOLT

- 10.9.3.10. CHECK OF PRIMARY BELT CONVEYOR

- 10.9.3.11. CHECK OF GRIZZLY FEEDER

- 10.9.4. EVERY 100 HOURS SERVICE

- 10.9.4.1. GREASING JAW CRUSHER BEARINGS

- 10.9.4.2. DRAINING WATER AND SEDIMENT FROM FUEL TANK

- 10.9.4.3. GREASING PRIMARY BELT CONVEYOR

- 10.9.5. EVERY 250 HOURS SERVICE

- 10.9.5.1. CHECK OF BATTERY FLUID LEVEL

- 10.9.5.2. CHECK AND ADJUSTMENT OF ENGINE FAN BELT TENSION

- 10.9.5.3. CHECK AND ADJUSTMENT OF JAW CRUSHER DRIVE VBELT TENSION

- 10.9.5.4. CHECK AND REPLENISHMENT OF OIL IN CRUSHER MOTOR BEARING CASE

- 10.9.6. EVERY 500 HOURS SERVICE

- 10.9.6.1. REPLACEMENT OF OIL IN ENGINE OIL PAN AND ENGINE OIL FILTER CARTRIDGE

- 10.9.6.2. REPLACEMENT OF FUEL FILTER CARTRIDGE

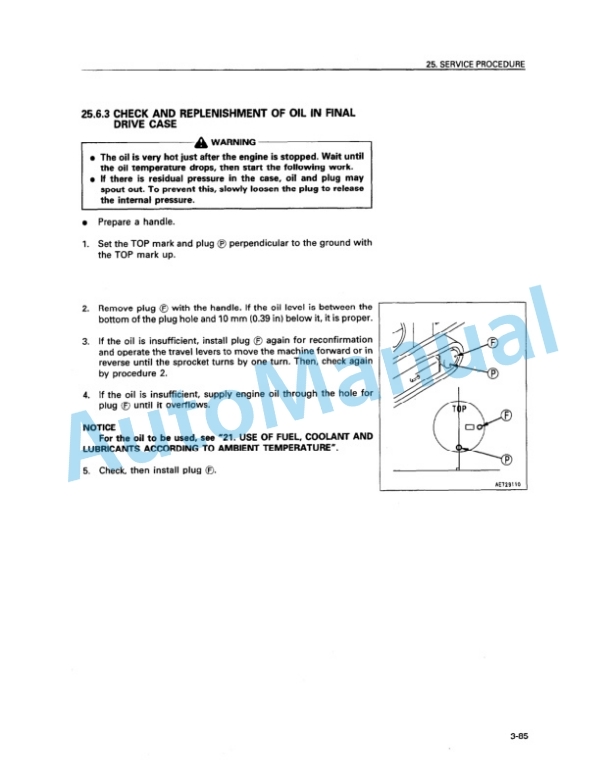

- 10.9.6.3. CHECK AND REPLENISHMENT OF OIL IN FINAL DRIVE CASE

- 10.9.6.4. REPLACEMENT OF HYDRAULIC OIL FILTER ELEMENT

- 10.9.7. EVERY 1000 HOURS SERVICE

- 10.9.7.1. REPLACEMENT OF OIL IN JAW CRUSHER MOTOR BEARING CASE

- 10.9.7.2. REPLACEMENT OF OIL IN GRIZZLY FEEDER VIBRATOR CASE

- 10.9.7.3. REPLACEMENT OF OIL IN DAMPER CASE

- 10.9.7.4. REPLACEMENT OF OIL IN CONVEYOR MOTOR MACHINERY CASE

- 10.9.8. EVERY 2000 HOURS SERVICE

- 10.9.8.1. REPLACEMENT OF OIL IN FINAL DRIVE CASE

- 10.9.8.2. CHECK OF EACH CLAMPED PARTS OF TURBOCHARGER

- 10.9.8.3. CHECK OF TURBOCHARGER ROTOR FOR PLAY

- 10.9.8.4. CHECK OF ALTERNATOR AND STARTING MOTOR

- 10.9.8.5. CHECK AND ADJUSTMENT OF ENGINE VALVE CLEARANCE

- 10.9.9. EVERY 4000 HOURS SERVICE

- 10.9.9.1. CHECK OF WATER PUMP

- 10.9.10. EVERY 5000 HOURS SERVICE

- 10.9.10.1. REPLACEMENT OF OIL IN HYDRAULIC TANK AND CLEANING OF STRAINER

- 11. SPECIFICATIONS

- 11.1. SPECIFICATIONS

- 12. OPTIONS, ATTACHMENTS

- 12.1. GENERAL PRECAUTIONS

- 12.1.1. PRECAUTIONS RELATED TO SAFETY

- 12.2. HYDRAULIC SECONDARY BELT CONVEYOR

- 12.2.1. SPECIFICATION

- 12.2.2. GENERAL VIEW

- 12.2.3. INCLINED LEG CONNECTING METHOD

- 12.2.4. LIFTING METHOD

- 12.2.5. CONNECTING METHOD TO MACHINE BODY

- 12.2.6. PRECAUTIONS ON OPERATION

- 12.2.7. INSPECTION, MAINTENANCE AND ADJUSTMENT

- 12.2.8. TROUBLES AND CORRECTIVE ACTIONS

- 12.2.9. CONSUMABLE PARTS OF HYDRAULIC SECONDARY BELT CONVEYOR

- 12.3. HYDRAULIC MAGNETIC SEPARATOR

- 12.3.1. SPECIFICATION (KMG900S)

- 12.3.2. GENERAL VIEW (KMG900S)

- 12.3.3. SPECIFICATION (KMG900L)

- 12.3.4. GENERAL VIEW (KMG900L)

- 12.3.5. PRECAUTIONS ON SAFETY

- 12.3.6. CONNECTING METHOD TO MACHINE BODY

- 12.3.7. PRECAUTIONS FOR USE

- 12.3.8. INSPECTION AND ADJUSTMENT

- 12.3.9. TROUBLES AND CORRECTIVE ACTIONS

- 12.3.10. MAINTENANCE SCHEDULE CHART

- 12.3.11. CONSUMABLE PARTS OF HYDRAULIC MAGNETIC SEPARATOR

- 12.4. HYDRAULIC VIBRATING SCREEN

- 12.4.1. SPECIFICATION

- 12.4.2. GENERAL VIEW

- 12.4.3. CAUTIONS TO BE NOTED FOR SAFETY

- 12.4.4. CONNECTING METHOD TO MACHINE BODY

- 12.4.5. PRECAUTIONS DURING OPERATION

- 12.4.6. TROUBLESHOOTING

- 12.4.7. CONSUMABLE PARTS OF HYDRAULIC VIBRATING SCREEN

- 12.4.8. SCREEN STRUCTURE

- 12.5. DEBRIS DISCHARGE CONVEYOR

- 12.5.1. SPECIFICATION

- 12.5.2. ASSEMBLY PROCEDURE

- 12.5.3. CONSUMABLE PARTS OF DEBRIS DISCHARGE CONVEYOR

- 12.5.4. OTHERS

- 12.6. RADIO CONTROL UNIT

- 12.6.1. SPECIFICATION

- 12.6.2. OUTLINE

- 12.6.3. METHOD OF APPLICATION

- 12.6.4. TROUBLES AND CORRECTIVE ACTIONS

- 12.7. GRIZZLY BAR OPENING

- 12.7.1. GRIZZLY BAR OPENING

- 12.8. CONVEYOR PROTECTION PLATE

- 12.8.1. CONVEYOR PROTECTION PLATE

- 12.9. METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS

- 12.9.1. POSITION FOR OPTION CONNECTION COUPLER

- 12.9.2. PROCEDURE FOR CONNECTING OPTIONS

- 12.10. TROUBLESHOOTING OF OPTION SYSTEM

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081