Komatsu D65EX-15, D65PX-15, D65WX-15 Bull Dozer Operation and Maintenance Manual TEN00057-03

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: TEN00057-03

- Format: PDF

- Size: 7.3MB

- Number of Pages: 299

-

Model List:

- D65EX-15 Bull Dozer

- D65PX-15 Bull Dozer

- D65WX-15 Bull Dozer

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.3.2. VISIBILITY FROM OPERATORS SEAT

- 2.4. NECESSARY INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. ENGINE SERIAL NO. PLATE

- 2.4.3. POSITION OF SERVICE METER

- 2.4.4. TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR

- 2.5. CONTENTS

- 3. SAFETY

- 3.1. SAFETY

- 3.2. SAFETY LABELS

- 3.2.1. POSITIONS OF SAFETY PICTOGRAMS

- 3.2.2. SAFETY LABELS

- 3.2.3. WARNING TAG

- 3.3. GENERAL PRECAUTIONS

- 3.4. PRECAUTIONS FOR OPERATION

- 3.4.1. STARTING ENGINE

- 3.4.2. OPERATION

- 3.4.3. TRANSPORTATION

- 3.4.4. BATTERY

- 3.4.5. TOWING

- 3.5. PRECAUTIONS FOR MAINTENANCE

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. GENERAL VIEW OF MACHINE

- 4.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

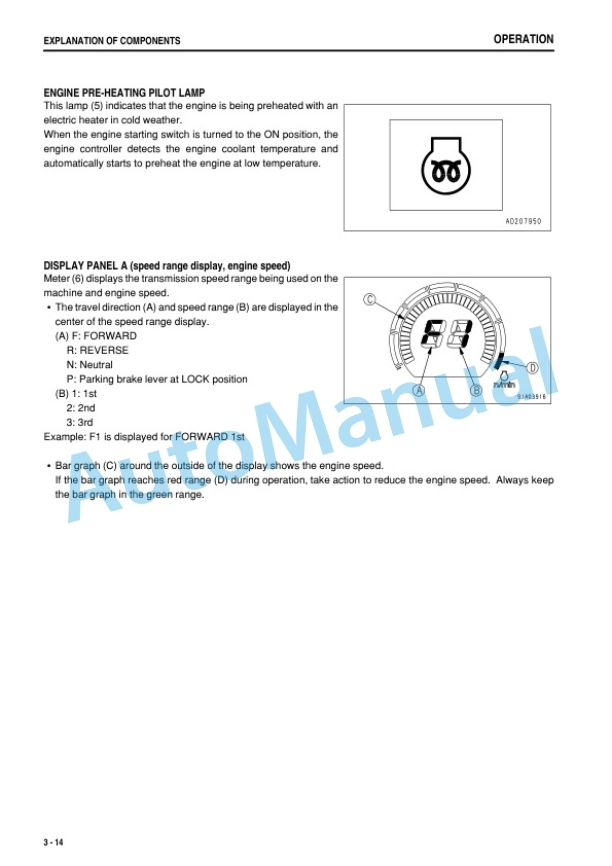

- 4.2. EXPLANATION OF COMPONENTS

- 4.2.1. FRONT PANEL

- 4.2.2. SWITCHES

- 4.2.3. CONTROL LEVERS AND PEDALS

- 4.2.4. CIRCUIT BREAKER

- 4.2.5. FUSE

- 4.2.6. FUSIBLE LINK

- 4.2.7. ELECTRIC POWER TAKEOUT ADAPTER

- 4.2.8. CAP WITH LOCK

- 4.2.9. DOOR OPEN LOCK

- 4.2.10. SASH GLASS INTERMEDIATE LOCK

- 4.2.11. DOOR POCKET

- 4.2.12. OPENING AND CLOSING ENGINE SIDE COVER

- 4.2.13. ASHTRAY

- 4.2.14. CUP HOLDER

- 4.2.15. TOOL BOX

- 4.2.16. SHOVEL HOLDER

- 4.2.17. CAR STEREO, HANDLING

- 4.2.18. AIR CONDITIONER, HANDLING

- 4.3. OPERATION

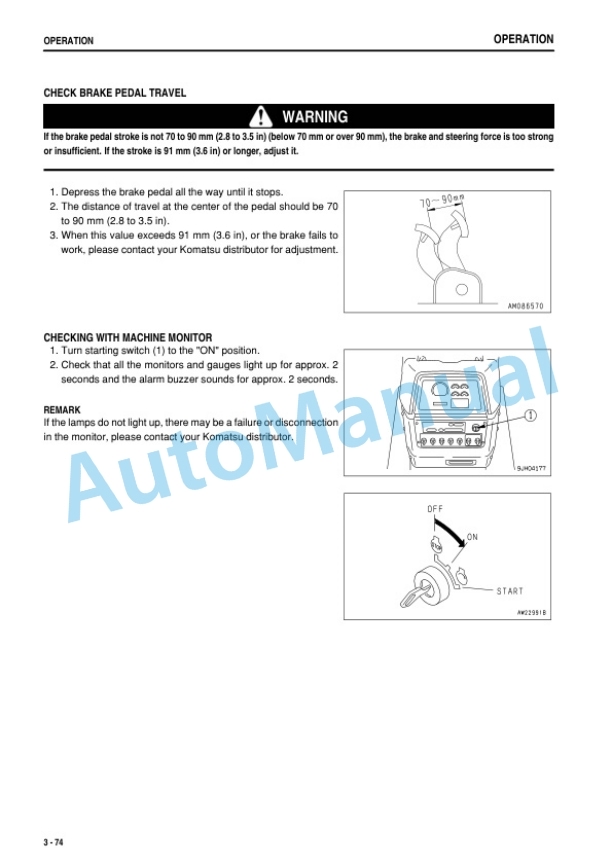

- 4.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 4.3.2. STARTING ENGINE

- 4.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 4.3.4. STOPPING ENGINE

- 4.3.5. MACHINE OPERATION

- 4.3.6. SHIFTING GEARS

- 4.3.7. SHIFTING BETWEEN FORWARD AND REVERSE

- 4.3.8. STEERING MACHINE

- 4.3.9. PRECAUTIONS FOR OPERATION

- 4.3.10. WORK POSSIBLE USING BULLDOZER

- 4.3.11. ADJUSTING POSTURE OF WORK EQUIPMENT

- 4.3.12. PARKING MACHINE

- 4.3.13. CHECK AFTER FINISHING WORK

- 4.3.14. LOCKING

- 4.3.15. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 4.4. TRANSPORTATION

- 4.4.1. TRANSPORTATION MEANS

- 4.4.2. REMOVING CAB

- 4.4.3. PRECAUTIONS WHEN REMOVING WORK EQUIPMENT

- 4.4.4. PRECAUTIONS WHEN REMOVING ROPS

- 4.4.5. LOADING, UNLOADING WORK

- 4.4.6. LIFTING MACHINE

- 4.4.7. TRAVELING ON ROADS

- 4.5. COLD WEATHER OPERATION

- 4.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 4.5.2. AFTER COMPLETION OF WORK

- 4.5.3. AFTER COLD WEATHER

- 4.6. LONGTERM STORAGE

- 4.6.1. BEFORE STORAGE

- 4.6.2. DURING STORAGE

- 4.6.3. AFTER STORAGE

- 4.7. TROUBLESHOOTING

- 4.7.1. AFTER RUNNING OUT OF FUEL

- 4.7.2. METHOD OF TOWING MACHINE

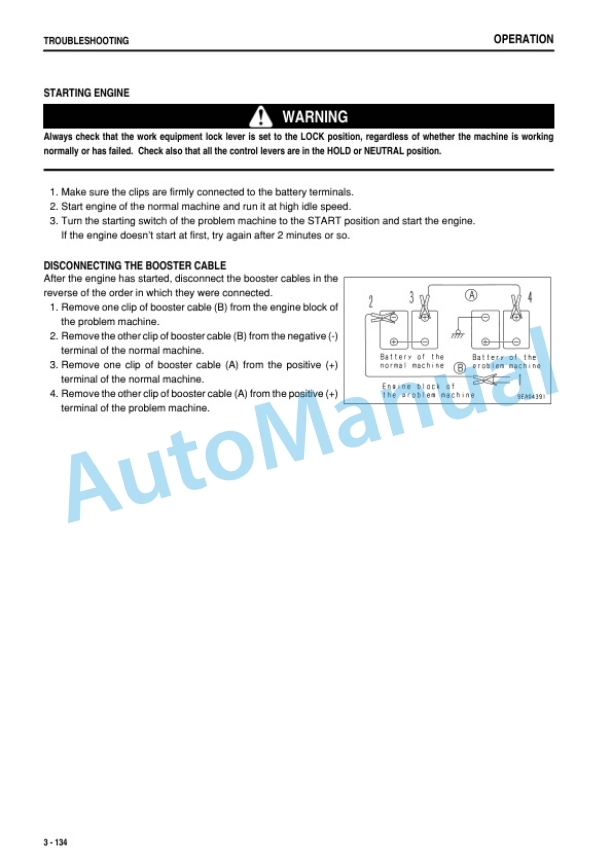

- 4.7.3. IF BATTERY IS DISCHARGED

- 4.7.4. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. GUIDE TO MAINTENANCE

- 5.2. OUTLINE OF SERVICE

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.2.2. RELATING TO ELECTRIC SYSTEM

- 5.2.3. HANDLING HYDRAULIC SYSTEM

- 5.3. WEAR PARTS LIST

- 5.3.1. WEAR PARTS LIST

- 5.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 5.4.1. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 5.4.2. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 5.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 5.5.1. TORQUE LIST

- 5.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5.6.1. SAFETY CRITICAL PARTS

- 5.7. MAINTENANCE SCHEDULE CHART

- 5.7.1. MAINTENANCE SCHEDULE CHART

- 5.7.2. ADJUST INJECTOR

- 5.8. SERVICE PROCEDURE

- 5.8.1. WHEN REQUIRED

- 5.8.2. CHECK BEFORE STARTING

- 5.8.3. EVERY 50 HOURS SERVICE

- 5.8.4. EVERY 250 HOURS SERVICE

- 5.8.5. EVERY 500 HOURS SERVICE

- 5.8.6. EVERY 1000 HOURS SERVICE

- 5.8.7. EVERY 2000 HOURS SERVICE

- 5.8.8. EVERY 4000 HOURS SERVICE

- 5.8.9. EVERY 8000 HOURS SERVICE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS, OPTIONS

- 7.1. GENERAL PRECAUTIONS

- 7.1.1. PRECAUTIONS RELATED TO SAFETY

- 7.2. SELECTION OF TRACK SHOE

- 7.2.1. METHOD OF SELECTING SHOES

- 7.3. HANDLING HYDRAULIC RIPPER

- 7.3.1. GENERAL VIEW

- 7.3.2. EXPLANATION OF COMPONENTS

- 7.3.3. OPERATION

- 7.3.4. TROUBLESHOOTING

- 7.3.5. MAINTENANCE

- 7.3.6. SPECIFICATIONS

- 7.4. HANDLING TRIMMING DOZER

- 7.4.1. GENERAL VIEW

- 7.4.2. EXPLANATION OF COMPONENTS

- 7.4.3. OPERATION

- 7.4.4. MAINTENANCE

- 7.4.5. SPECIFICATIONS

- 7.5. AIR SUSPENSION SEAT

- 7.6. DELUXE SEAT

- 7.7. HEADREST

- 7.8. EQUIPPING FIRE EXTINGUISHER AND FIRSTAID KIT

- 7.9. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 7.9.1. BASIC PRECAUTIONS

- 8. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001