Komatsu MX9 Operation and Maintenance Manual 054-110

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 054-110

- Format: PDF

- Size: 5.8MB

- Number of Pages: 211

-

Model List:

- MX9

- 1. MAIN MENU

- 2. Cover

- 3. Foreword

- 3.1. Your Machine Serial Numbers and Dealer

- 3.2. Safety Information

- 3.2.1. Signal Words

- 3.2.2. Example of Safety Message Using Signal Word

- 3.2.3. Other Signal Words

- 3.2.4. Safety Labels

- 3.2.5. Example of Safety Label Using Words

- 3.2.6. Example of Safety Label Using Pictogram

- 3.3. Introduction

- 3.3.1. Directions of Machine

- 3.4. Product Information

- 3.4.1. Machine Serial Number Plate and Its Location

- 3.4.2. Engine Serial Number Plate and Its Location

- 3.4.3. Emission Control Information Label and Its Location

- 3.4.4. Service Meter Location

- 3.5. Contents

- 4. Safety

- 4.1. Safety Labels

- 4.1.1. Location of Safety Labels

- 4.1.2. Safety Labels

- 4.2. Safety Information

- 4.2.1. Safety Rules

- 4.2.2. If Abnormalities Are Found

- 4.2.3. Working Wear and Personal Protective Items

- 4.2.4. Fire Extinguisher and First Aid Kit

- 4.2.5. Safety Equipment

- 4.2.6. Keep Machine Clean

- 4.2.7. Keep Operators Compartment Clean

- 4.2.8. Leaving Operators Seat with Lock

- 4.2.9. Handrails and Steps

- 4.2.10. Mounting and Dismounting

- 4.2.11. No Persons on Attachments

- 4.2.12. Burn Prevention

- 4.2.13. Fire Prevention and Explosion Prevention

- 4.2.14. Action If Fire Occurs

- 4.2.15. Falling Objects, Flying Objects and Intruding Objects Prevention

- 4.2.16. Attachment Installation

- 4.2.17. Attachment Combinations

- 4.2.18. Unauthorized Modifications

- 4.2.19. Safety at Jobsite

- 4.2.20. Working on Loose Ground

- 4.2.21. Distance to High Voltage Cables

- 4.2.22. Ensure Good Visibility

- 4.2.23. Ventilation for Enclosed Area

- 4.2.24. Signalpersons Signal and Signs

- 4.2.25. Asbestos Dust Hazard Prevention

- 4.3. Safe Machine Operation

- 4.3.1. Starting Engine

- 4.3.2. Operation

- 4.3.3. Transportation

- 4.3.4. Battery

- 4.3.5. Towing

- 4.3.6. Lifting Objects with Bucket

- 4.4. Safe Maintenance Information

- 4.4.1. Warning Tag

- 4.4.2. Keep Work Place Clean and Tidy

- 4.4.3. Appoint Leader When Working with Others

- 4.4.4. Stop Engine Before Carrying Out Maintenance

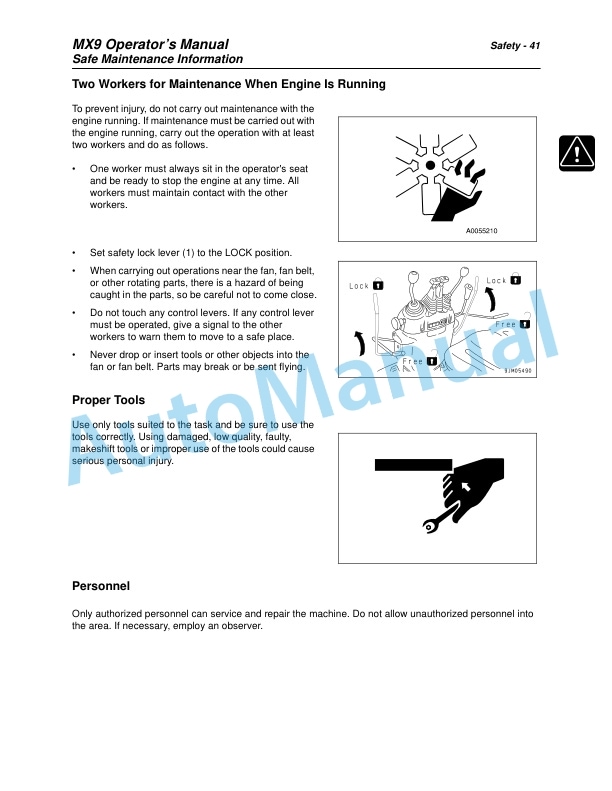

- 4.4.5. Two Workers for Maintenance When Engine Is Running

- 4.4.6. Proper Tools

- 4.4.7. Personnel

- 4.4.8. Attachments

- 4.4.9. Work Under the Machine

- 4.4.10. Noise

- 4.4.11. When Using Hammer

- 4.4.12. Welding Works

- 4.4.13. Removing Battery Terminals

- 4.4.14. Safety First When Using HighPressure Grease to Adjust Track Tension

- 4.4.15. Safety Rules for HighPressure Oil

- 4.4.16. Safety Handling HighPressure Hoses

- 4.4.17. Waste Materials

- 4.4.18. Compressed Air

- 4.4.19. Periodic Replacement of Safety Critical Parts

- 5. Operation

- 5.1. Machine View Illustrations

- 5.1.1. Overall Machine View

- 5.1.2. Controls and Gauges

- 5.2. Detailed Controls and Gauges

- 5.2.1. Meters and Lamps

- 5.2.2. Switches

- 5.2.3. Control Levers and Pedals

- 5.2.4. Variable Blade

- 5.2.5. Engine Hood

- 5.2.6. Fuse

- 5.2.7. InLine Fuse

- 5.2.8. Operators Manual Storage

- 5.3. Machine Operations and Controls

- 5.3.1. Before Starting Engine

- 5.3.2. Starting Engine

- 5.3.3. After Starting Engine

- 5.3.4. Stopping the Engine

- 5.3.5. Check After Shutting Off Engine

- 5.3.6. Machine Operation

- 5.3.7. Steering the Machine

- 5.3.8. Swinging

- 5.3.9. Backhoe Controls and Operations

- 5.3.10. Prohibited Operations

- 5.3.11. General Operation Information

- 5.3.12. Traveling on Slopes

- 5.3.13. Escape from Mud

- 5.3.14. Recommended Applications

- 5.3.15. Bucket Replacement

- 5.3.16. Parking Machine

- 5.3.17. Machine Inspection After Daily Work

- 5.3.18. Rubber Tracks

- 5.4. Transportation

- 5.4.1. Transportation Procedure

- 5.4.2. Loading and Unloading with Trailer

- 5.4.3. Lifting Machine

- 5.4.4. Shipping Machine Information

- 5.5. Cold Weather Operation

- 5.5.1. Cold Weather Operation Information

- 5.5.2. After Daily Work Completion

- 5.5.3. After Cold Weather Season

- 5.6. LongTerm Storage

- 5.6.1. Before Storage

- 5.6.2. During Storage

- 5.6.3. After Storage

- 5.6.4. Starting Machine After LongTerm Storage

- 5.7. Troubles and Actions

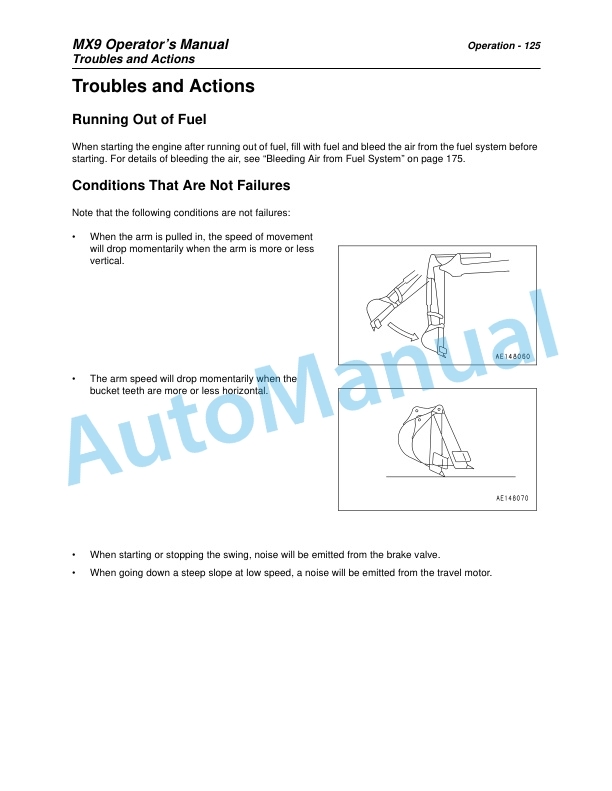

- 5.7.1. Running Out of Fuel

- 5.7.2. Conditions That Are Not Failures

- 5.7.3. Towing the Machine

- 5.7.4. Severe Job Conditions

- 5.7.5. Discharged Battery

- 5.7.6. Battery Removal and Installation

- 5.7.7. Battery Charging

- 5.7.8. Starting Engine with Jumper Cables

- 5.7.9. Other Trouble

- 6. Maintenance

- 6.1. Maintenance Information

- 6.2. Lubricants, Coolant, and Filters

- 6.2.1. Handling Oil, Fuel, and Coolant

- 6.2.2. Electrical System Maintenance

- 6.3. Lubricants, Fuel, and Coolant Specifications

- 6.3.1. Proper Selection

- 6.4. Tightening Torque Specifications

- 6.4.1. Tightening Torque List

- 6.5. Maintenance Schedule

- 6.5.1. Maintenance Interval for Hydraulic Breaker

- 6.6. Maintenance Procedure

- 6.6.1. Initial 250 Hour Maintenance (Only After the First 250 Hours)

- 6.6.2. When Required

- 6.6.2.1. Clean and Replace Air Cleaner Element

- 6.6.2.2. Flush Cooling System

- 6.6.2.3. Check Level of Battery Electrolyte

- 6.6.2.4. Check Rubber Tracks

- 6.6.2.5. Check and Adjust Track Tension

- 6.6.2.6. Drain Water and Sediment from Fuel Tank

- 6.6.3. Checks Before Starting

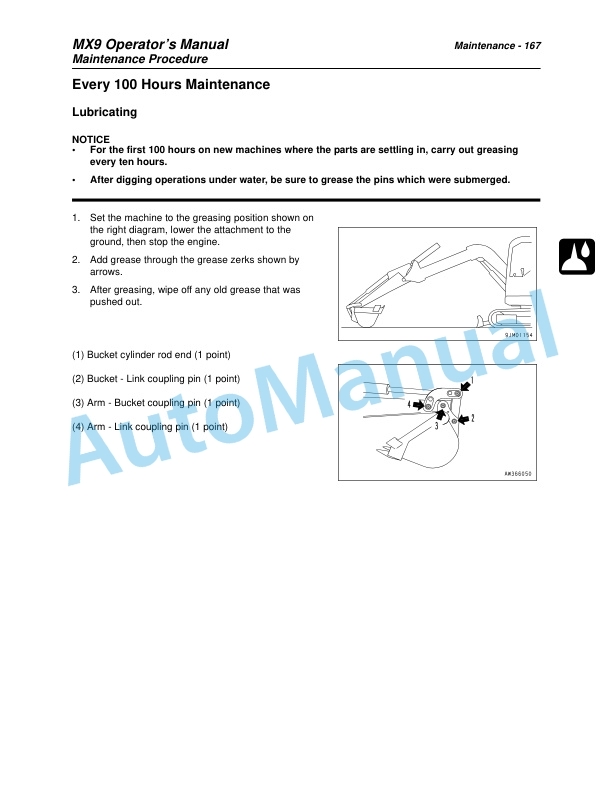

- 6.6.4. Every 100 Hours Maintenance

- 6.6.4.1. Lubricating

- 6.6.5. Every 250 Hours Maintenance

- 6.6.5.1. Lubricating

- 6.6.5.2. Replace Engine Oil

- 6.6.5.3. Check Oil Level In Final Drive Case, Add Oil

- 6.6.5.4. Replace Hydraulic Filter Element

- 6.6.5.5. Check and Adjust Cooling Fan Belt Tension

- 6.6.6. Every 500 Hours Maintenance

- 6.6.6.1. Lubricating

- 6.6.6.2. Replace Engine Oil Filter Element

- 6.6.6.3. Replace Fuel Filter Element

- 6.6.6.4. Replace Fuel Feed Pump PreFilter

- 6.6.6.5. Clean and Inspect Radiator Fins and Oil Cooler Fins

- 6.6.7. Every 1000 Hours Maintenance

- 6.6.7.1. Change Oil In Final Drive Case

- 6.6.8. Every 2000 Hours Maintenance

- 6.6.8.1. Change Oil In Hydraulic Tank, Clean Strainer

- 6.6.8.2. Check Alternator and Starting Motor

- 6.6.8.3. Check and Adjust Engine Valve Clearance

- 7. Specifications

- 8. Attachments and Options

- 8.1. General Information

- 8.1.1. Safety First

- 8.1.2. Attachment Installation

- 8.2. Bucket with Hook

- 8.2.1. Hook Condition

- 8.2.2. Prohibited Operations

- 8.3. Attachment Guide

- 8.3.1. Attachment Combinations

- 8.4. Handling Arm with BuiltIn Breaker

- 8.4.1. Bucket Position

- 8.4.2. Removing and Installing Chisel

- 8.4.3. Procedure for Breaker Operations

- 8.4.4. Precautions When Carrying Out Breaker Operations

- 8.4.5. Stowing Chisel, Dummy Chisel

- 8.4.6. Precautions When Carrying Out Bucket Operations

- 8.4.7. Handling Dummy Link

- 8.4.8. Check Before Starting

- 8.4.9. Specifications

- 8.5. Handling Bucket Coupler

- 8.5.1. Procedure for Removing Bucket

- 8.5.2. Procedure for Installing Bucket

- 8.6. Recommended Attachment Operations

- 8.6.1. Hydraulic Breaker

- 9. Support

- 9.1. Procedure

- 9.2. Resources

- 9.2.1. Publications

- 9.2.2. Ditch Witch Training

- 10. Warranty

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745