Komatsu PC4300LC-7E0 Hydraulic Excavator Operation and Maintenance Manual CEAM017002

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM017002

- Format: PDF

- Size: 8.4MB

- Number of Pages: 312

-

Model List:

- PC4300LC-7E0 Hydraulic Excavator

- 1. FOREWORD

- 2. SAFETY INFORMATION

- 3. INTRODUCTION

- 3.1. INTENDED USE

- 3.2. FEATURES

- 3.3. DIRECTIONAL REFFERENCE OF MACHINE

- 3.4. BREAKING IN A NEW MACHINE

- 3.5. PLATE LOCATIONS

- 3.6. TABLE TO ENTER SERIAL NUMBERS AND DISTRIBUTOR

- 4. TABLE OF CONTENTS

- 5. SAFETY AND WARNING DECALS

- 5.1. LOCATION OF THE SAFETY DECALS

- 5.2. SAFETY LABELS

- 6. GENERAL SAFETY RULES AND PRECAUTIONS

- 6.1. GENERAL SAFETY RULES

- 6.2. SAFETY FEATURES

- 6.3. PERSONAL PROTECTIVE EQUIPMENT

- 6.4. FIRE AND EXPLOSION PREVENTION

- 6.5. ACTION IF FIRE OCCURS

- 6.6. DUST HAZARD PRECAUTIONS

- 6.7. KEEP OPERATORS COMPARTMENT CLEAN

- 6.8. LEAVING OPERATORS SEAT WITH LOCK

- 6.9. MOUNTING AND DISMOUNTING

- 6.10. FIRE EXTINGUISHER AND FIRST AID KIT

- 6.11. INSIDE OPERATORS COMPARTMENT

- 6.12. PROTECTION AGAINST FALLING OR FLYING OBJECTS

- 6.13. PRECAUTIONS FOR ATTACHMENTS

- 7. PRECAUTIONS BEFORE STARTING OPERATIONS

- 7.1. PREOPERATIONAL CHECKS

- 7.2. STARTING YOUR WORK OPERATIONS

- 7.3. WORK SITE HAZZARDS

- 7.4. AVOIDING DANGEROUS SITUATIONS

- 7.5. WORKING CLEARANCES

- 7.6. OPERATIONS ON SLOPES

- 7.7. OPERATIONS ON SNOW

- 8. RULES FOR ROAD TRAVEL

- 8.1. TRAVELING WITH CARRAGE REVERSED

- 8.2. TRAVEL ON SLOPES

- 8.3. PARKING THE MACHINE

- 9. PRECAUTIONS DURING MAINTENANCE OPERATIONS

- 9.1. WARNING TAGS

- 9.2. EQUIPMENT STORAGE

- 9.3. WORKING UNDER THE MACHINE

- 9.4. USING DROP LAMPS

- 9.5. KEEPING THE MACHINE CLEAN

- 9.6. PERFORMING GENERAL MAINTENANCE PROCEDURES

- 9.7. RUNNING THE ENGINE DURING MAINTENANCE

- 9.8. PROPER TOOLS

- 9.9. WELDING, GRINDING OR CUTTING

- 9.10. ADJUSTING TRACK TENSION

- 9.11. DO NOT DISASSEMBLE RECOIL SPRINGS

- 9.12. WHEN USING HAMMER

- 9.13. RULES FOR REFUELING THE MACHINE

- 9.14. COOLING SYSTEM PRECAUTIONS

- 9.15. BATTERY PRECAUTIONS

- 9.16. STARTING PRECAUTIONS

- 9.17. HIGH PRESSURE HOSES

- 9.18. PRECAUTION FOR HIGH FUEL PRESSURE

- 9.19. HIGH TEMPERATURES AREAS

- 9.20. DISPOSAL OF WASTE MATERIALS

- 9.21. ACCUMULATOR

- 9.22. CRITICAL PARTS

- 9.23. HIGH VOLTAGE

- 9.24. TOWING

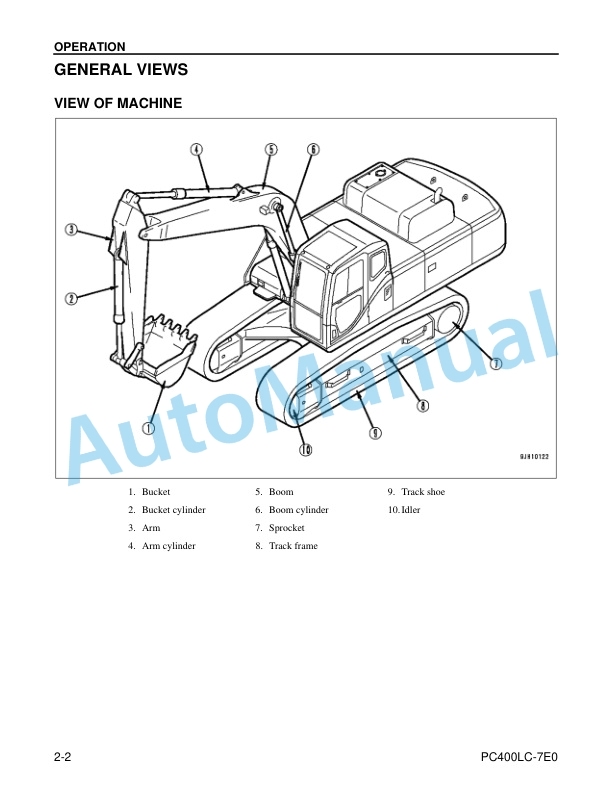

- 10. GENERAL VIEWS

- 10.1. VIEW OF MACHINE

- 10.2. VIEW CONTROLS AND GAUGES

- 11. MACHINE MONITOR SYSTEM

- 11.1. MONITOR BEZEL LAYOUT

- 11.2. BASIC OPERATION OF MACHINE MONITOR

- 12. MONITOR CHECK ITEMS

- 12.1. EMERGENCY ALERTS

- 12.2. WARNING ALERTS

- 12.3. CHECK ALERTS

- 12.4. METER DISPLAY

- 13. MONITOR SWITCHES

- 13.1. SWITCH LAYOUT VIEW

- 14. CONSOLE CONTROL SWITCHES

- 14.1. SWITCH LAYOUT VIEW.

- 15. CONTROL LEVERS AND PEDALS

- 16. LEVER LAYOUT VIEW

- 16.1. SAFETY LOCK LEVER

- 16.2. TRAVEL LEVERS

- 16.3. WORK EQUIPMENT CONTROL LEVER

- 16.4. CAB EMERGENCY EXIT WINDOW

- 17. SAFETY LOCKS AND SECURITY

- 17.1. DOOR LOCK

- 17.2. CAP, COVER WITH LOCK

- 17.3. LOCKABLE AREAS

- 18. ADDTIONAL FEATURES AND ACCESSORIES

- 18.1. HOT AND COOL BOX

- 18.2. STORAGE BOX WITH CUP HOLDER

- 18.3. ASHTRAY

- 18.4. AUTOTEMP AIR CONDITIONER

- 18.5. RADIO

- 18.6. TOOLBOX

- 18.7. GREASE GUN HOLDER

- 18.8. AUXILIARY POWER PORTS

- 19. FUSES AND FUSE LINKS

- 19.1. FUSES

- 19.2. FUSIBLE LINK

- 20. PRECAUTIONS BEFORE STARTING WORK OPERATIONS

- 20.1. PREOPERATIONAL CHECKS

- 20.2. STARTING THE ENGINE

- 21. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 21.1. BREAKING IN THE MACHINE

- 21.2. STOPPING THE ENGINE

- 22. MOVING, STOPPING AND PARKING THE MACHINE

- 22.1. PREPARATIONS FOR MOVING THE MACHINE

- 22.2. TURNING THE MACHINE

- 22.3. SWINGING

- 22.4. GENERAL TRAVELING

- 22.5. PARKING MACHINE

- 23. STARTING YOUR WORK OPERATIONS

- 23.1. AVOIDING DANGEROUS SITUATIONS

- 23.2. WORKING CLEARANCES

- 23.3. OPERATIONS ON SLOPES

- 23.4. OPERATIONS ON SNOW

- 23.5. WORK EQUIPMENT OVERVIEW

- 23.6. OPERATING MODES

- 23.7. EXCAVATING PROCEDURES

- 24. BUCKET REPLACEMENT AND INVERSION

- 24.1. BUCKET REPLACEMENT

- 24.2. BUCKET INVERSION

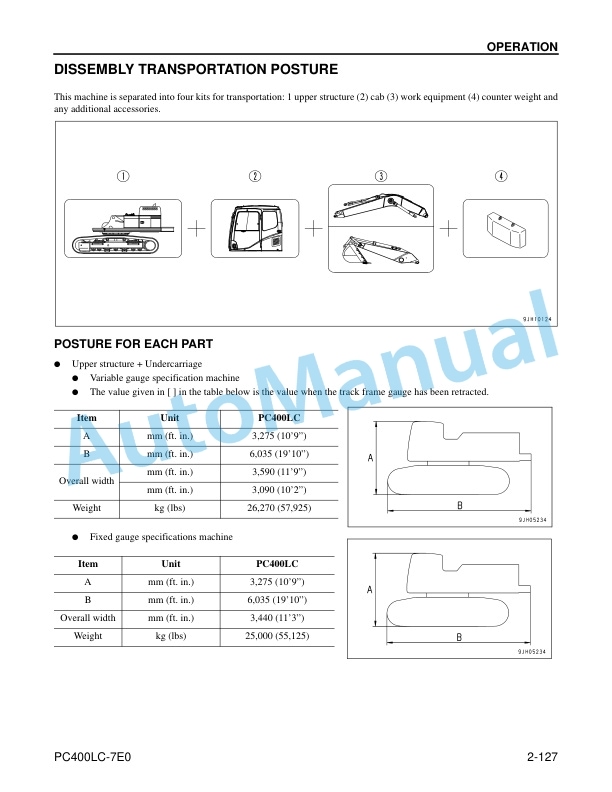

- 25. TRANSPORTING THE MACHINE

- 25.1. LOADING AND UNLOADING A TRAILER

- 25.2. LIFTING THE MACHINE

- 25.3. DISSEMBLY TRANSPORTATION POSTURE

- 25.4. TOWING THE MACHINE

- 26. INCREASING OR REDUCING TRACK FRAME GAUGE

- 26.1. REDUCING TRACK GAUGE

- 26.2. INCREASING TRACK GAUGE

- 27. COLD WEATHER OPERATION

- 27.1. FUEL AND LUBRICANTS

- 27.2. COOLING SYSTEM COOLANT

- 27.3. BATTERY

- 27.4. MONITOR

- 27.5. PRECAUTIONS ON PARTICULAR JOBSITES

- 27.6. DISCHARGED BATTERY

- 28. GENERAL TROUBLESHOOTING

- 28.1. AFTER RUNNING OUT OF FUEL

- 28.2. PHENOMENA THAT ARE NOT FAILURES

- 28.3. ELECTRICAL SYSTEM PROBLEMS

- 28.4. CHASSIS PROBLEMS

- 28.5. ENGINE PROBLEMS

- 28.6. ELECTRONIC CONTROL SYSTEM

- 28.7. TELEPHONE WHEN ERROR OCCURS

- 29. LONG TERM STORAGE

- 29.1. BEFORE STORAGE

- 29.2. DURING STORAGE

- 29.3. AFTER STORAGE

- 30. MAINTENANCE INFORMATION

- 30.1. SERVICE METER READING

- 30.2. KOMATSU GENUINE REPLACEMENT PARTS

- 30.3. KOMATSU GENUINE LUBRICANTS

- 30.4. WINDSHIELD WASHER FLUID

- 30.5. FRESH AND CLEAN LUBRICANTS

- 30.6. CHECK DRAINED OIL AND USED FILTER

- 30.7. FUEL STRAINER

- 30.8. WELDING INSTRUCTIONS

- 30.9. DO NOT DROP THINGS INSIDE MACHINE

- 30.10. SELECTING FUEL AND LUBRICANTS TO MATCH AMBIENT TEMPERATURE

- 30.11. DUSTY JOBSITE

- 30.12. AVOID MIXING LUBRICANTS

- 30.13. LOCKING THE INSPECTION COVERS

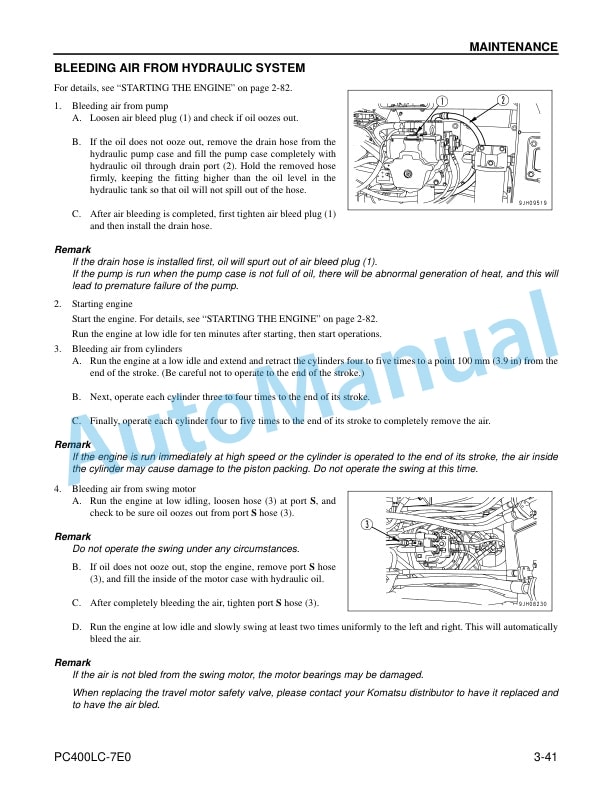

- 30.14. HYDRAULIC SYSTEM AIR BLEEDING

- 30.15. HYDRAULIC HOSE INSTALLATION

- 30.16. CHECKS AFTER INSPECTION AND MAINTENANCE WORKS

- 31. LUBRICANTS, COOLANT AND FILTERS

- 31.1. OUTLINE OF SERVICE

- 31.2. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 31.3. ELECTRIC SYSTEM MAINTENANCE

- 31.4. HANDLING HYDRAULIC SYSTEM

- 32. WEAR PARTS LIST

- 33. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 33.1. RECOMMENDED PRODUCTS OTHER THAN KOMATSU GENUINE OILS

- 34. TIGHTENING TORQUE SPECIFICATIONS

- 35. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 35.1. SAFETY RELATED CRITICAL PARTS

- 36. MAINTENANCE SCHEDULE

- 36.1. MAINTENANCE SCHEDULE CHART

- 36.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 37. MAINTENANCE PROCEDURE

- 37.1. INITIAL 1000 HOURS MAINTENANCE (ONLY AFTER THE FIRST 1000 HOURS)

- 37.2. WHEN REQUIRED

- 37.3. CHECK BEFORE STARTING

- 37.4. EVERY 50 HOURS MAINTENANCE

- 37.5. EVERY 250 HOURS MAINTENANCE

- 37.6. EVERY 500 HOURS MAINTENANCE

- 37.7. EVERY 1000 HOURS MAINTENANCE

- 37.8. EVERY 2000 HOURS MAINTENANCE

- 37.9. EVERY 4000 HOURS MAINTENANCE

- 37.10. EVERY 5000 HOURS MAINTENANCE

- 37.11. EVERY 8000 HOURS MAINTENANCE

- 38. SPECIFICATIONS

- 39. GENERAL PRECAUTIONS

- 39.1. PRECAUTIONS RELATED TO SAFETY

- 39.2. PRECAUTIONS FOR ATTACHMENT REMOVAL AND INSTALLATION

- 39.3. PRECAUTIONS WHEN USING LARGE IMPLEMENTS

- 39.4. HANDLING BUCKET WITH HOOK

- 40. MACHINES READY FOR ATTACHMENTS

- 40.1. EXPLANATION OF COMPONENTS

- 40.2. HYDRAULIC CIRCUIT

- 40.3. ATTACHMENT INSTALLATION AND REMOVAL PROCEDURE

- 40.4. ATTACHMENT OPERATIONS

- 40.5. LONG TERM STORAGE

- 40.6. SPECIFICATIONS

- 41. ATTACHMENT GUIDE

- 41.1. COMBINATIONS OF WORK EQUIPMENT

- 41.2. SELECTION OF TRACK SHOES

- 42. HYDRAULIC BREAKER

- 42.1. MAIN APPLICATIONS

- 43. Blank Page

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729