- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PC95-1 Hydraulic Excavator Operation and Maintenance Manual EEAM004900

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: EEAM004900

- Format: PDF

- Size: 30.2MB

- Number of Pages: 147

-

Model List:

- PC95-1 Hydraulic Excavator

- 1. MAIN MENU

- 2. CONTENTS

- 3. FOREWORD

- 4. SAFETY INFORMATION

- 5. INTRODUCTION

- 6. PERMITTED USES

- 7. MAIN FEATURES

- 8. RUNNING IN THE MACHINE

- 9. LOCATION OF MACHINE COMPONENT IDENTIFICATION PLATES

- 10. SERIAL NUMBERS AND ADDRESS OF DEALER

- 11. SAFETY AND ACCIDENT PREVENTION

- 11.1. SAFETY MEASURES

- 11.1.1. GENERAL PRECAUTIONS

- 11.1.2. SAFETY DEVICES

- 11.1.3. PERSONAL PROTECTIVE CLOTHING AND EQUIPMENT

- 11.1.4. UNAUTHORISED MODIFICATIONS

- 11.1.5. LEAVING THE DRIVING SEAT

- 11.1.6. ENTERING AND LEAVING THE MACHINE

- 11.1.7. PREVENTION OF FUEL AND OIL FIRES

- 11.1.8. PREVENTION OF BURNS AND SCALDING

- 11.1.9. PREVENTION OF ASBESTOS DUST CONTAMINATION

- 11.1.10. PREVENTION OF INJURY BY WORK EQUIPMENT

- 11.1.11. FIRE EXTINGUISHERS AND FIRST AID KIT

- 11.1.12. PRECAUTIONS REGARDING THE CAB FRAME

- 11.1.13. PRECAUTIONS REGARDING EQUIPMENT

- 12. PRECAUTIONS

- 12.1. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

- 12.1.1. ONSITE SAFETY

- 12.1.2. FIRE PREVENTION

- 12.1.3. PRECAUTIONS REGARDING THE CAB

- 12.1.4. VENTILATION OF ENCLOSED AREAS

- 12.1.5. CLEANING WINDOWS, MIRRORS AND HEADLIGHTS CHECKING WIPER BLADES, LAMPS

- 12.2. PRECAUTIONS TO BE TAKEN WHILE WORKING

- 12.2.1. STARTING THE ENGINE

- 12.2.2. CHECKS PRIOR TO REVERSING

- 12.2.3. MOVING THE MACHINE

- 12.2.4. WORKING ON SLOPES

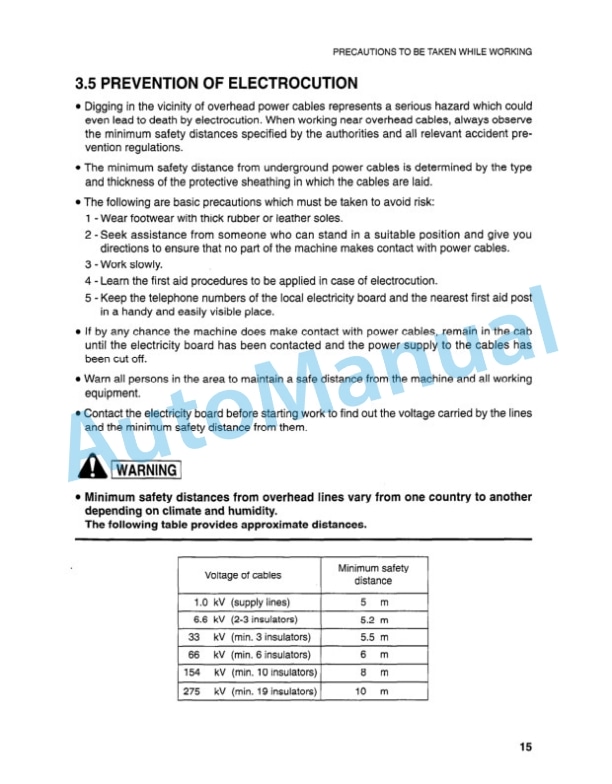

- 12.2.5. PREVENTION OF ELECTROCUTION

- 12.2.6. VISIBILITY

- 12.2.7. WORKING ON FROZEN OR SNOWCOVERED GROUND

- 12.2.8. PREVENTION OF DAMAGE BY THE EQUIPMENT

- 12.2.9. WORKING ON LOOSE OR PLOUGHED SOIL

- 12.2.10. PARKING THE MACHINE

- 12.3. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE

- 12.3.1. LOADING AND UNLOADING

- 12.3.2. THE ROUTE

- 12.4. THE BATTERY

- 12.4.1. SAFETY PRECAUTIONS FOR WORK ON BATTERIES

- 12.4.2. STARTING THE ENGINE WITH JUMP LEADS

- 12.5. PRECAUTIONS FOR EMERGENCY RECOVERY

- 12.6. PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

- 12.6.1. WARNING NOTICES

- 12.6.2. TOOLS

- 12.6.3. PERSONAL PRECAUTIONS

- 12.6.4. EQUIPMENT

- 12.6.5. KEEPING THE MACHINE CLEAN

- 12.6.6. RUNNING THE ENGINE DURING MAINTENANCE

- 12.6.7. RULES FOR REFUELLING AND ADDING OIL

- 12.6.8. LEVEL OF COOLANT IN THE RADIATOR

- 12.6.9. USING LAMPS

- 12.6.10. BATTERY AND ALTERNATOR PRECAUTIONS

- 12.6.11. PRECAUTIONS REGARDING HIGH PRESSURE HOSES

- 12.6.12. PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH PRESSURE SYSTEMS

- 12.6.13. PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES

- 12.6.14. THE RADIATOR COOLING FAN AND FAN BELT

- 12.7. SAFETY AND NOISE ABATEMENT NOTICES

- 12.7.1. LOCATION OF SAFETY NOTICES

- 12.7.2. LOCATION OF NOISE ABATEMENT NOTICES

- 13. TECHNICAL SPECIFICATIONS

- 13.1. OVERALL DIMENSIONS WITH MONOBLOCK BOOM

- 13.2. OVERALL DIMENSIONS WITH ARTICULATED BOOM

- 13.3. TECHNICAL SPECIFICATIONS

- 14. THE MACHINE AND ITS OPERATIONS

- 14.1. SAFETY DEVICES

- 14.1.1. EQUIPMENT SAFETY DEVICES

- 14.2. GENERAL VIEWS

- 14.2.1. GENERAL VIEW (MONOBLOCK BOOM)

- 14.2.2. GENERAL VIEW (ARTICULATED BOOM)

- 14.2.3. GENERAL VIEW OF INSIDE OF CAB

- 14.3. INSTRUMENTS AND CONTROLS

- 14.3.1. INSTRUMENTS, WARNING LIGHTS, AND PUSHBUTTONS

- 14.3.1.1. INSTRUMENTS

- 14.3.1.2. WARNING LIGHTS AND INDICATORS

- 14.3.1.3. PUSHBUTTONS AND SWITCHES

- 14.3.2. LOCATION OF MACHINE CONTROLS

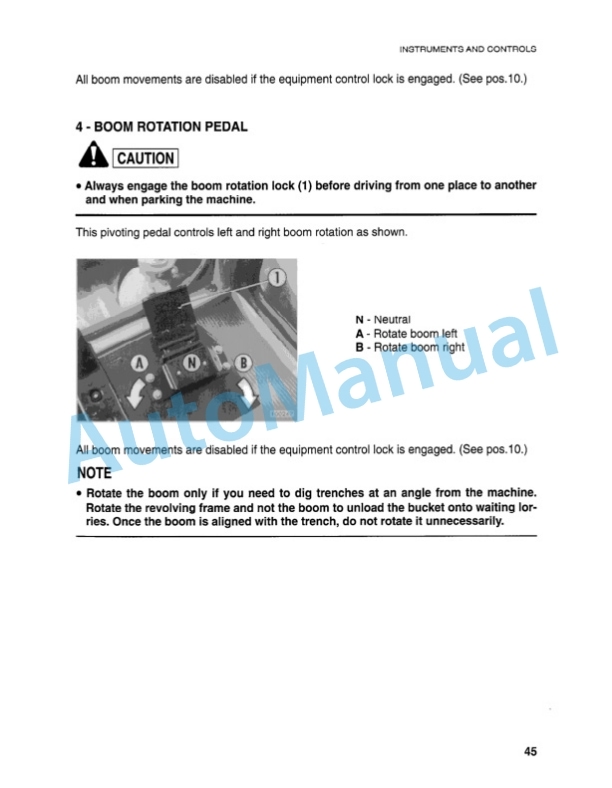

- 14.3.2.1. MACHINE CONTROLS

- 14.4. FUSES AND RELAYS

- 14.4.1. FUSES

- 14.4.2. RELAYS

- 14.5. THE CAB AND DRIVING POSITION

- 14.5.1. THE CAB

- 14.5.2. VENTILATION AND HEATING

- 14.5.3. THE DRIVING SEAT

- 14.5.4. THE SAFETY BELT

- 14.6. OPERATING THE MACHINE

- 14.6.1. CHECKS PRIOR TO STARTING THE ENGINE

- 14.6.1.1. VISUAL CHECKS

- 14.6.1.2. DAILY CHECKS

- 14.6.1.3. OPERATING CHECKS

- 14.6.2. STARTING THE ENGINE

- 14.6.2.1. STARTING A WARM ENGINE AND STARTING IN WARM WEATHER

- 14.6.2.2. STARTING A COLD ENGINE AND STARTING IN COLD WEATHER

- 14.6.3. WARMING UP THE ENGINE

- 14.6.4. WARMING UP THE HYDRAULIC FLUID

- 14.6.5. MOVING THE MACHlNE

- 14.6.5.1. STEERING AND DIRECTION CHANGING

- 14.6.5.2. NEGOTIATING SLOPES

- 14.6.5.3. MAXIMUM DEPTH OF WATER

- 14.7. PARKING THE MACHINE

- 14.7.1. PARKING ON LEVEL GROUND

- 14.7.2. PARKING ON A SLOPE

- 14.8. STOPPING THE ENGINE

- 14.9. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE

- 14.9.1. LOADING AND UNLOADING

- 14.9.2. THE ROUTE

- 14.10. COLD WEATHER PRECAUTIONS

- 14.10.1. FUEL AND LUBRICANTS

- 14.10.2. COOLANT

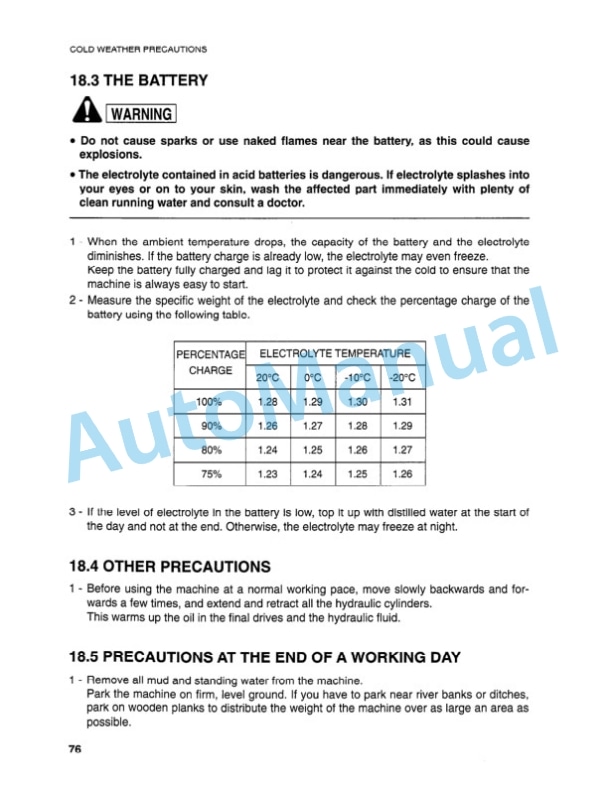

- 14.10.3. THE BATTERY

- 14.10.4. OTHER PRECAUTIONS

- 14.10.5. PRECAUTIONS AT THE END OF A WORKING DAY

- 14.11. WARM WEATHER PRECAUTIONS

- 14.12. USING THE WORK EQUIPMENT

- 14.12.1. ORGANISATION OF THE WORK AREA

- 14.12.2. POSITIONING THE BUCKET ACCORDING TO THE JOB

- 14.12.3. POSITIONING THE MACHINE FOR DIGGING

- 14.12.4. DIGGING METHOD

- 14.12.5. CHANGING THE WORK EQUIPMENT

- 14.12.5.1. CHANGING THE BUCKET

- 14.13. FAULT FINDING

- 14.13.1. RUNNING OUT OF FUEL

- 14.13.2. IF THE BATTERY IS FLAT

- 14.13.2.1. USING JUMP LEADS TO START THE ENGINE

- 14.13.3. OTHER FAULTS

- 14.13.3.1. ELECTRICAL SYSTEM

- 14.13.3.2. ENGINE

- 14.13.3.3. HYDRAULIC SYSTEM

- 15. MAINTENANCE

- 15.1. MAINTENANCE GUIDE

- 15.2. MAINTENANCE NOTES

- 15.2.1. ENGINE MAINTENANCE NOTES

- 15.2.1.1. ENGINE OIL

- 15.2.1.2. COOLING WATER

- 15.2.1.3. FUEL

- 15.2.2. HYDRAULIC SYSTEM MAINTENANCE NOTES

- 15.2.3. ELECTRICAL SYSTEM MAINTENANCE NOTES

- 15.2.4. NOTES ON LUBRICATION

- 15.2.5. PARTS SUBJECT TO RAPID WEAR AND REQUIRING REGULAR REPLACEMENT

- 15.3. FUEL, COOLANT, AND LUBRICANTS

- 15.4. NUT AND BOLT TIGHTENING TORQUES

- 15.4.1. STANDARD TIGHTENING TORQUES

- 15.4.2. SPECIAL TIGHTENING TORQUES

- 15.5. SCHEDULED MAINTENANCE

- 15.5.1. PRESTARTING CHECKS

- 15.5.1.1. a VARIOUS CHECKS

- 15.5.1.2. b CHECKING THE COOLANT LEVEL

- 15.5.1.3. c CHECKING THE FUEL LEVEL

- 15.5.1.4. d CHECKING THE ENGINE OIL LEVEL

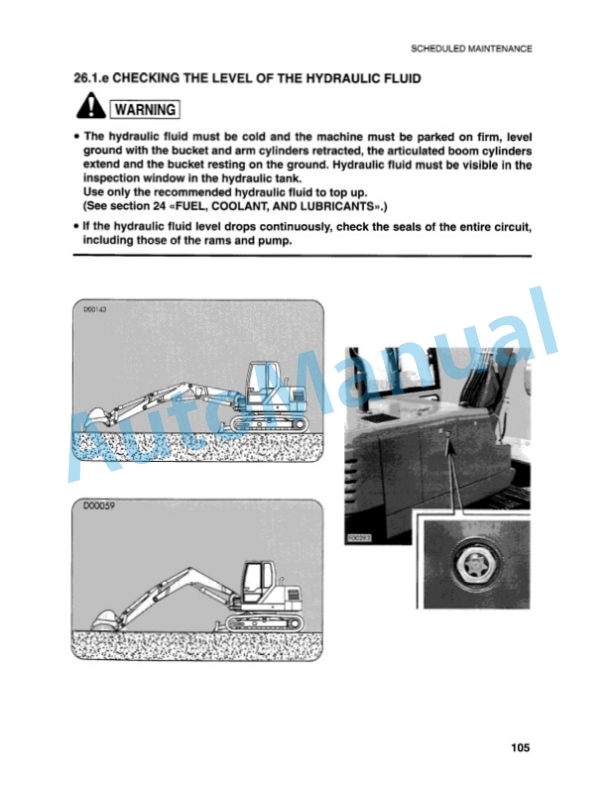

- 15.5.1.5. e CHECKING THE LEVEL OF THE HYDRAULIC FLUID

- 15.5.1.6. f CHECKING THE ELECTRICAL SYSTEM

- 15.5.1.7. g DRAINING THE FUEL LINE WATER TRAP

- 15.5.2. AFTER THE FIRST 50 HOURS

- 15.5.3. EVERY 50 HOURS

- 15.5.3.1. a GREASING THE SWIVEL JOINT

- 15.5.3.2. b CLEANING THE ENGINE AIR FILTER DUST TRAP

- 15.5.4. EVERY 100 HOURS

- 15.5.4.1. a GREASING THE ARTICULATIONS

- 15.5.4.2. b CLEANING THE MAIN AIR FILTER ELEMENT

- 15.5.5. AFTER THE FIRST 250 HOURS

- 15.5.6. EVERY 250 HOURS

- 15.5.6.1. a ADJUSTING FAN BELT TENSION

- 15.5.6.2. b CHECKING THE ELECTROLYTE LEVEL IN THE BATTERY

- 15.5.6.3. c CHECKING THE OIL LEVEL IN THE FINAL DRIVES

- 15.5.6.4. d CHECKING THE OIL LEVEL IN THE SWING MOTOR

- 15.5.6.5. e CHANGING THE HYDRAULIC SYSTEM FILTER ELEMENT

- 15.5.6.6. f CHANGING THE SERVOCONTROL FILTER ELEMENT

- 15.5.6.7. g CHANGING THE ENGINE OIL

- 15.5.6.8. h CHANGING THE ENGINE OIL FILTER

- 15.5.7. EVERY 500 HOURS

- 15.5.7.1. a CHANGING THE MAIN AIR FILTER ELEMENT

- 15.5.7.2. b DRAINING THE FUEL TANK

- 15.5.7.3. c CLEANING THE OUTSIDE OF THE RADIATOR

- 15.5.7.4. d CHANGING THE FUEL FILTER AND CLEANING THE FUEL PUMPS GAUZE FILTER

- 15.5.7.5. e CHECKING THE GREASE LEVEL IN THE FIFTH WHEEL PINION GEAR

- 15.5.7.6. f GREASING THE FIFTH WHEEL

- 15.5.8. EVERY 1000 HOURS

- 15.5.8.1. a CHANGING THE AIR FILTER BACKUP ELEMENT

- 15.5.9. EVERY 2000 HOURS

- 15.5.9.1. a CHANGING THE HYDRAULIC FLUID

- 15.5.9.2. b CHANGING THE FINAL DRIVES OIL

- 15.5.9.3. c CHANGING THE SWING MOTOR OIL

- 15.5.9.4. d CHANGING THE GREASE IN THE FIFTH WHEEL PINION GEAR

- 15.5.9.5. e CHANGING THE COOLANT

- 15.5.9.6. f CHECKING ENGINE VALVE CLEARANCE

- 15.5.9.7. g CHECKING THE ALTERNATOR AND STARTER MOTOR

- 15.5.10. OCCASIONAL MAINTENANCE

- 15.5.10.1. a WASHING OUT THE COOLING SYSTEM

- 15.5.10.2. b ADJUSTING TRACK TENSION

- 15.5.10.3. c CHECKING THE SECURITY OF THE TRACK SHOES

- 15.6. EXTENDED PERIODS OF DISUSE

- 15.6.1. PREPARING TO LAY UP THE MACHINE

- 15.6.2. PREPARING THE MACHINE FOR USE

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF