Komatsu PW75R-2 Hydraulic Excavator Operation and Maintenance Manual WEAM001401

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: WEAM001401

- Format: PDF

- Size: 5.1MB

- Number of Pages: 224

-

Model List:

- PW75R-2 Hydraulic Excavator

- 1. FOREWORD

- 2. INFORMATION ON SAFETY

- 3. INTRODUCTION

- 3.1. INTENDED USES

- 3.2. IMPROPER OR UNAUTHORIZED USE

- 3.3. MAIN CHARACTERISTICS

- 3.4. RUNNINGIN

- 4. PRODUCT IDENTIFICATION

- 4.1. MACHINE SERIAL NUMBER

- 4.2. MACHINE IDENTIFICATION PLATE

- 4.3. ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

- 4.4. FRONT AXLE SERIAL NUMBER

- 4.5. REAR AXLE SERIAL NUMBER

- 4.6. SWING REDUCTION GEAR SERIAL NUMBER

- 4.7. CAB SERIAL NUMBER

- 4.8. SERIAL NUMBERS AND DEALERS ADDRESS

- 5. CONTENTS

- 6. SAFETY, NOISE AND VIBRATION PLATES

- 6.1. POSITION OF THE SAFETY PLATES

- 6.2. PICTOGRAMS AND RELEVANT MEANINGS

- 6.3. POSITION OF THE NOISE PLATES

- 6.4. VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

- 7. GENERAL PRECAUTIONS

- 7.1. GENERAL SAFETY RULES

- 7.2. SAFETY DEVICES AND GUARDS

- 7.3. CLOTHING AND PERSONAL PROTECTION ITEMS

- 7.4. UNAUTHORIZED MODIFICATIONS

- 7.5. LEAVING THE OPERATORS SEAT

- 7.6. GETTING ON AND OFF THE MACHINE

- 7.7. CHECKING THE REARVIEW MIRRORS

- 7.8. PREVENTING FIRES DUE TO FUEL AND OIL

- 7.9. PREVENTING BURNS

- 7.10. PREVENTING DAMAGE DUE TO ASBESTOS POWDER

- 7.11. PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT

- 7.12. FIRE EXTINGUISHERS AND FIRST AID KIT

- 7.13. PRECAUTIONS CONCERNING THE CAB STRUCTURE

- 7.14. PRECAUTIONS CONCERNING THE EQUIPMENT

- 8. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

- 8.1. SAFETY ON THE WORK SITE

- 8.2. FIRE PREVENTION

- 8.3. PRECAUTIONS TO BE TAKEN FOR THE OPERATORS CAB

- 8.4. ROOM VENTILATION

- 8.5. PRECAUTIONS TO BE TAKEN FOR THE LIGHTS

- 8.6. CLEANING THE WINDOWS AND THE REARVIEW MIRRORSCHECKING THE WINDSHIELD WIPER BLADES

- 9. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 9.1. STARTING THE ENGINE

- 9.2. CHECK THE DIRECTION BEFORE STARTING THE MACHINE

- 9.3. RULES FOR TRAVELLING ON ROADS

- 9.4. CHECKS FOR TRAVELLING IN REVERSE

- 9.5. MOVING THE MACHINE

- 9.6. MOVING ON SLOPES

- 9.7. WORKING ON SLOPES

- 9.8. UNAUTHORIZED OPERATIONS

- 9.9. PREVENTING ELECTROCUTION

- 9.10. VISIBILITY

- 9.11. WORKING ON ICY OR SNOWCOVERED SURFACES

- 9.12. PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT

- 9.13. WORKING ON LOOSE GROUND

- 9.14. PARKING THE MACHINE

- 10. TRANSPORTING THE MACHINE ON OTHER VEHICLES

- 10.1. LOADING AND UNLOADING THE MACHINE

- 10.2. SHIPPING

- 11. BATTERY

- 11.1. SAFETY PRECAUTIONS FOR WORK ON BATTERIES

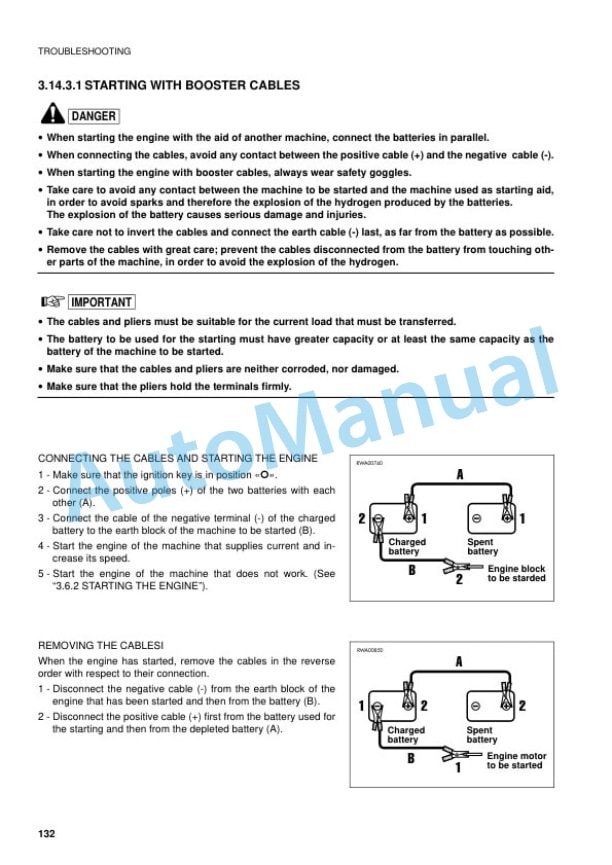

- 11.2. STARTING WITH BOOSTER CABLES

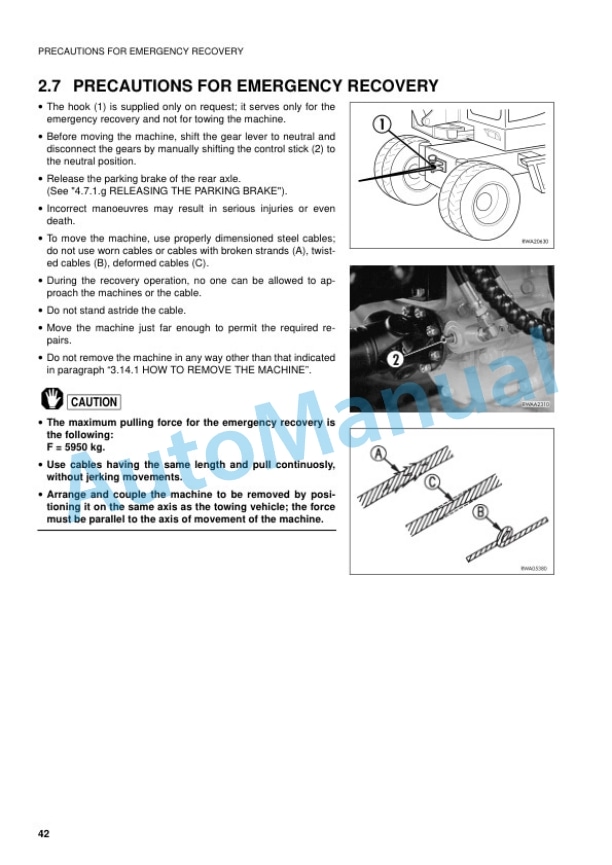

- 12. PRECAUTIONS FOR EMERGENCY RECOVERY

- 13. PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

- 13.1. WARNING PLATES

- 13.2. TOOLS

- 13.3. PERSONNEL

- 13.4. EQUIPMENT

- 13.5. WORKING UNDER THE MACHINE

- 13.6. KEEPING THE MACHINE CLEAN

- 13.7. USE OF THE ENGINE DURING MAINTENANCE

- 13.8. PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY

- 13.9. STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION

- 13.10. RULES FOR REFUELLING AND ADDING OIL

- 13.11. CHECKING THE COOLANT LEVEL IN THE RADIATOR

- 13.12. USING LAMPS

- 13.13. PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR

- 13.14. PRECAUTIONS CONCERNING THE STARTER

- 13.15. PRECAUTIONS CONCERNING HIGHPRESSURE HOSES

- 13.16. PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGHPRESSURE SYSTEMS

- 13.17. PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES

- 13.18. COOLING FAN AND FAN BELT

- 13.19. WASTE MATERIALS

- 13.20. PRECAUTIONS FOR INFLATING TYRES

- 13.21. PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES

- 14. SAFETY LOCKS

- 14.1. MACHINE LOCKS

- 15. GENERAL VIEWS

- 15.1. FRONT GENERAL VIEW (MONOBOOM)

- 15.2. FRONT GENERAL VIEW (TWOPIECE BOOM)

- 15.3. REAR GENERAL VIEW (WITH STABILIZERS)

- 15.4. REAR GENERAL VIEW (WITH BLADE)

- 15.5. CAB INSIDE GENERAL VIEW

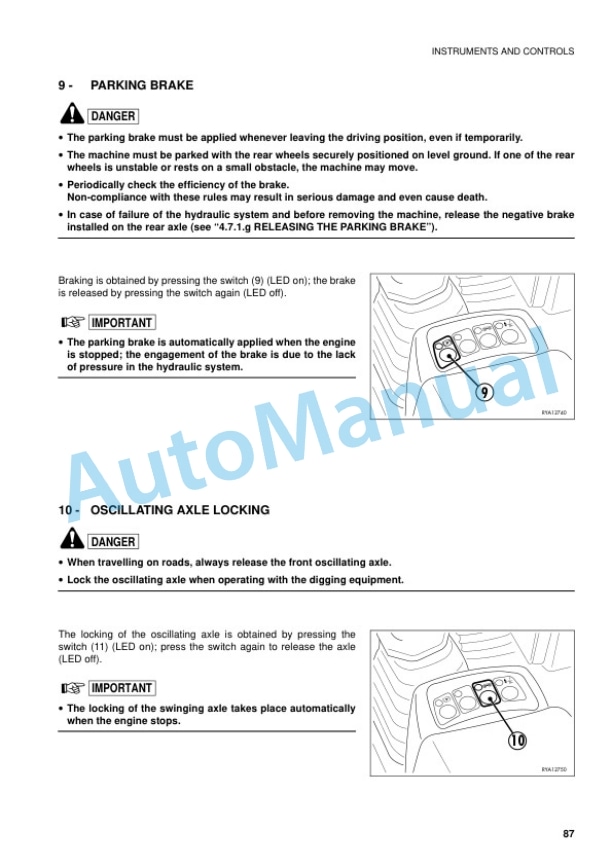

- 16. INSTRUMENTS AND CONTROLS

- 16.1. INSTRUMENTS

- 16.2. WARNING LIGHTS

- 16.3. SWITCHES AND PUSH BUTTONS

- 16.4. ELECTRICAL ACCESSORIES

- 16.5. MACHINE CONTROLS

- 17. FUSES AND RELAYS

- 17.1. CENTRAL UNIT FUSES AND RELAYS

- 17.2. ENGINE LINE FUSES AND RELAYS

- 18. GUARDS AND DRIVERS SEAT

- 18.1. ENGINE HOOD

- 18.2. SIDE COVER

- 18.4. VENTILATION AND HEATING

- 18.5. SEAT

- 18.6. SAFETY BELT

- 18.7. EMERGENCY EXIT

- 18.8. TECHNICAL DOCUMENTATION CASE

- 18.9. FIRE EXTINGUISHER

- 18.10. FIRST AID KIT

- 19. USE OF THE MACHINE

- 19.1. CHECKS BEFORE STARTING THE ENGINE

- 19.2. STARTING THE ENGINE

- 19.3. WARMING THE ENGINE

- 19.4. HEATING THE HYDRAULIC OIL

- 19.5. HOW TO MOVE THE MACHINE

- 20. PARKING THE MACHINE

- 20.1. PARKING ON LEVEL GROUND

- 20.2. PARKING ON SLOPES

- 21. STOPPING THE ENGINE

- 22. TRANSPORTING THE MACHINE ON OTHER VEHICLES

- 22.1. LOADING AND UNLOADING THE MACHINE

- 22.2. TRANSPORT

- 23. PRECAUTIONS TO BE TAKEN IN THE COLD SEASON

- 23.1. FUEL AND LUBRICANTS

- 23.2. COOLANT

- 23.3. BATTERY

- 23.4. OTHER PRECAUTIONS

- 23.5. PRECAUTIONS TO BE TAKEN AT THE END OF WORK

- 24. PRECAUTIONS TO BE TAKEN IN THE WARM SEASON

- 25. USING THE WORK EQUIPMENT

- 25.1. ORGANIZING THE WORK AREA

- 25.2. POSITIONING THE BUCKET ACCORDING TO THE WORK TO BE CARRIED OUT

- 25.3. POSITIONING THE MACHINE FOR DIGGING OPERATIONS

- 25.4. DIGGING METHOD

- 25.5. CHANGING THE BUCKET

- 26. LONG PERIODS OF INACTIVITY

- 26.1. BEFORE THE PERIOD OF INACTIVITY

- 26.2. DURING THE PERIOD OF INACTIVITY

- 26.3. AFTER THE PERIOD OF INACTIVITY

- 27. TROUBLESHOOTING

- 27.1. HOW TO REMOVE THE MACHINE

- 27.2. IF THE FUEL HAS BEEN COMPLETELY DEPLETED

- 27.3. IF THE BATTERY IS DEPLETED

- 27.4. OTHER TROUBLES

- 28. GUIDE TO MAINTENANCE

- 29. MAINTENANCE NOTES

- 29.1. NOTES REGARDING THE ENGINE

- 29.2. NOTES REGARDING THE HYDRAULIC SYSTEM

- 29.3. NOTES REGARDING THE ELECTRICAL SYSTEM

- 29.4. NOTES REGARDING LUBRICATION

- 29.5. PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING

- 30. FUEL, COOLANT AND LUBRICANTS

- 30.1. LUBRICATION WITH GREASE

- 30.2. HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS

- 31. DRIVING TORQUES FOR SCREWS AND NUTS

- 31.1. STANDARD DRIVING TORQUES

- 31.2. SPECIFIC DRIVING TORQUES

- 32. LUBRICATION

- 32.1. LUBRICATION DIAGRAM

- 33. PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY

- 33.1. CRITICAL PARTS FOR SAFETY

- 34. MAINTENANCE PLAN

- 34.1. WHEN REQUIRED

- 34.2. MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER

- 34.3. CHECKS BEFORE STARTING

- 34.4. MAINTENANCE EVERY 10 HOURS OF OPERATION

- 34.5. MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic…

- 34.6. MAINTENANCE EVERY 50 HOURS OF OPERATION

- 34.7. MAINTENANCE AFTER THE FIRST 100 HOURS OF OPERATION

- 34.8. MAINTENANCE EVERY 100 HOURS OF OPERATION

- 34.9. MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION

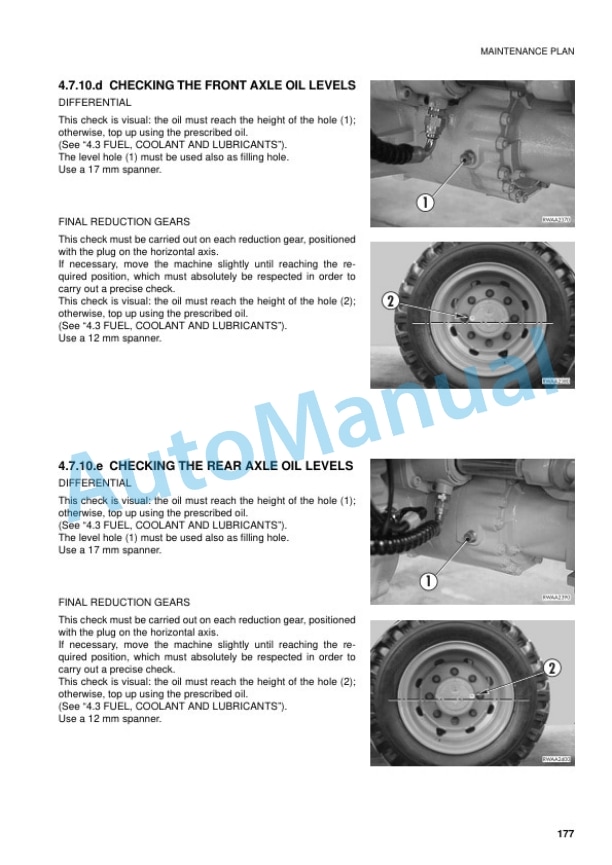

- 34.10. MAINTENANCE EVERY 250 HOURS OF OPERATION

- 34.11. MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the synthet…

- 34.12. MAINTENANCE EVERY 500 HOURS OF OPERATION

- 34.13. MAINTENANCE EVERY 1000 HOURS OF OPERATION

- 34.14. MAINTENANCE EVERY 2000 HOURS OF OPERATION

- 35. TECHNICAL DATA

- 35.1. STANDARD OVERALL DIMENSIONS

- 35.2. TECHNICAL CHARACTERISTICS

- 35.3. LIFTING CAPACITIES (Only for machines with overload alarm device)

- 36. AUTHORIZED OPTIONAL EQUIPMENT

- 36.1. PRECAUTIONS REGARDING SAFETY

- 36.2. PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT

- 36.3. CHARACTERISTICS OF THE OPTIONAL EQUIPMENT

- 37. ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER

- 37.1. DESCRIPTION AND OPERATION

- 37.2. USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED

- 37.3. ALWAYS AVOID THE FOLLOWING INCORRECT USES

- 37.4. INSTALLING AND REMOVING THE DEMOLITION HAMMER

- 37.5. MAINTENANCE

- 38. CLAMSHELL BUCKET

- 38.1. DESCRIPTION AND OPERATION

- 38.2. INSTALLING THE CLAMSHELL BUCKET

- 38.3. MAINTENANCE

- 38.4. POSITIONING THE CLAMSHELL BUCKET FOR ROAD TRAVEL

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745