- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA1200-3 Wheel Loader Operation and Maintenance Manual PEN00479-02

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: PEN00479-02

- Format: PDF

- Size: 9.7MB

- Number of Pages: 343

-

Model List:

- WA1200-3 Wheel Loader

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.3.2. VISIBILITY FROM OPERATORS SEAT

- 2.4. NECESSARY INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. ENGINE SERIAL NO. PLATE AND POSITION

- 2.4.3. POSITION OF SERVICE METER

- 2.4.4. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 2.5. CONTENTS

- 3. SAFETY

- 3.1. SAFETY

- 3.2. SAFETY LABELS

- 3.2.1. LOCATION OF SAFETY LABELS

- 3.2.2. SAFETY LABELS

- 3.2.3. GENERAL PRECAUTIONS

- 3.3. PRECAUTIONS FOR OPERATION

- 3.3.1. STARTING ENGINE

- 3.3.2. OPERATION

- 3.3.3. TRANSPORTATION

- 3.3.4. BATTERY

- 3.3.5. TOWING

- 3.4. PRECAUTIONS FOR MAINTENANCE

- 3.5. PRECAUTIONS WITH TIRES

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. GENERAL VIEW OF MACHINE

- 4.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 4.2. EXPLANATION OF COMPONENTS

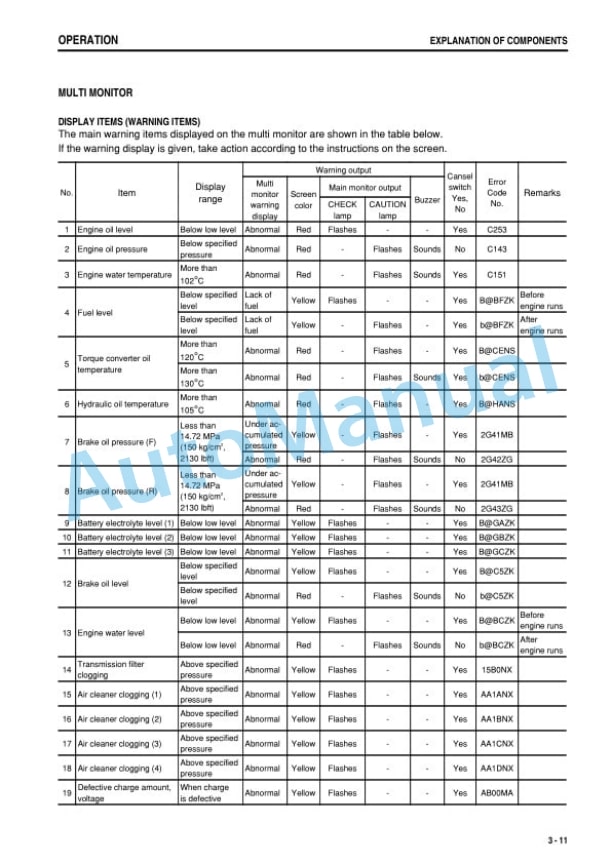

- 4.2.1. MACHINE MONITOR

- 4.2.2. SWITCHES

- 4.2.3. SWITCHES (MULTI MONITOR)

- 4.2.4. CONTROL LEVERS, PEDALS, KNOBS

- 4.2.5. CAB DOOR OPEN LOCK

- 4.2.6. TOOL BOX

- 4.2.7. FUSE

- 4.2.8. SLOW BLOW FUSE

- 4.2.9. LUNCH BOX TRAY

- 4.2.10. LOCATION OF FIRE EXTINGUISHER

- 4.2.11. POWER OUTLET

- 4.2.12. AM/FM RADIOCASSETTE STEREO

- 4.2.13. AIR CONDITIONER

- 4.2.14. PRECAUTIONS WHEN HANDLING ACCUMULATOR

- 4.3. OPERATION

- 4.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 4.3.2. STARTING ENGINE

- 4.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 4.3.4. STOPPING ENGINE

- 4.3.5. CHECK AFTER STOPPING ENGINE

- 4.3.6. MOVING THE MACHINE (DIRECTIONAL, SPEED), STOPPING THE MACHINE

- 4.3.7. TURNING

- 4.3.8. OPERATION OF WORK EQUIPMENT

- 4.3.9. WORK POSSIBLE USING WHEEL LOADER

- 4.3.10. PRECAUTIONS FOR OPERATION

- 4.3.11. ADJUSTING WORK EQUIPMENT POSTURE

- 4.3.12. PARKING MACHINE

- 4.3.13. CHECKS AFTER COMPLETION OF OPERATION

- 4.3.14. LOCKING

- 4.3.15. HANDLING THE TIRES

- 4.3.16. OPERATION OF MULTI MONITOR

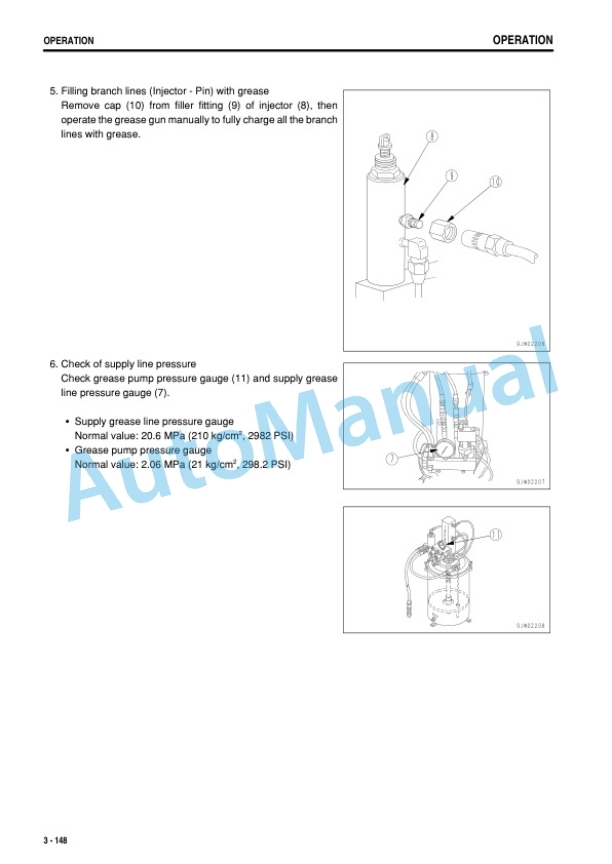

- 4.3.17. OPERATING AUTOGREASING SYSTEM

- 4.4. TRANSPORTATION

- 4.4.1. TRANSPORTATION PROCEDURE

- 4.4.2. LOADING, UNLOADING WORK

- 4.4.3. METHOD OF SECURING MACHINE

- 4.5. COLD WEATHER OPERATION

- 4.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 4.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 4.5.3. AFTER COLD WEATHER

- 4.5.4. WARMINGUP OPERATION FOR STEERING HYDRAULIC CIRCUIT IN COLD WEATHER

- 4.6. LONGTERM STORAGE

- 4.6.1. BEFORE STORAGE

- 4.6.2. DURING STORAGE

- 4.6.3. AFTER STORAGE

- 4.7. TROUBLESHOOTING

- 4.7.1. WHEN MACHINE RUNS OUT OF FUEL

- 4.7.2. METHOD OF TOWING MACHINE

- 4.7.3. IF BATTERY IS DISCHARGED

- 4.7.4. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. GUIDES TO MAINTENANCE

- 5.2. OUTLINES OF SERVICE

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.2.2. OUTLINE OF ELECTRIC SYSTEM

- 5.3. WEAR PARTS

- 5.3.1. WEAR PARTS LIST

- 5.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 5.4.1. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 5.4.2. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 5.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 5.5.1. TORQUE LIST

- 5.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5.6.1. SAFETY CRITICAL PARTS

- 5.7. MAINTENANCE SCHEDULE CHART

- 5.7.1. MAINTENANCE SCHEDULE CHART

- 5.8. SERVICE PROCEDURE

- 5.8.1. INITIAL 250 HOURS SERVICE

- 5.8.2. WHEN REQUIRED

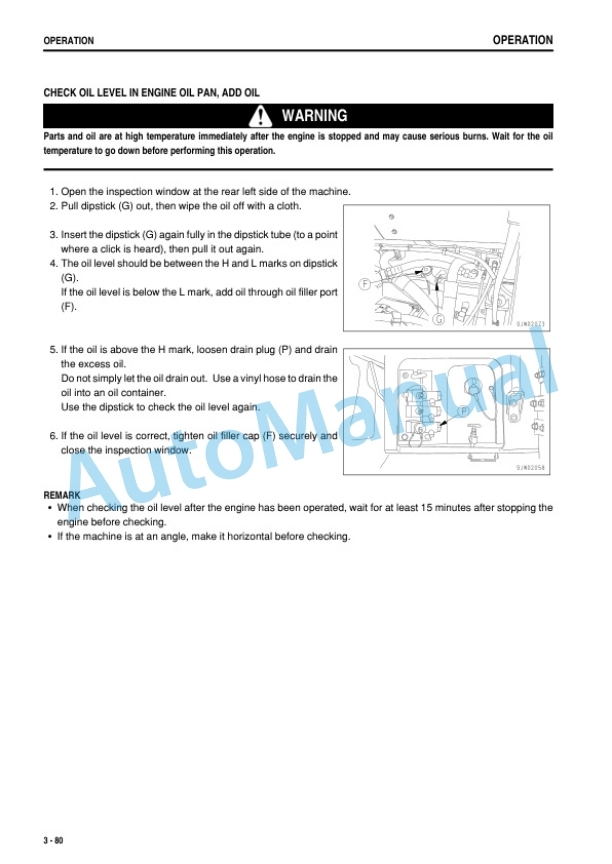

- 5.8.3. CHECK BEFORE STARTING

- 5.8.4. EVERY 50 HOURS SERVICE

- 5.8.5. EVERY 100 HOURS SERVICE

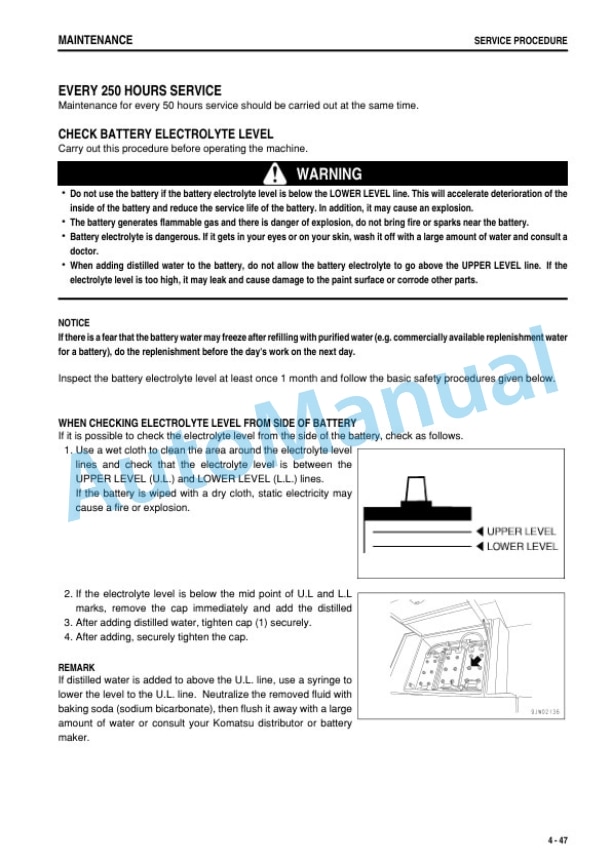

- 5.8.6. EVERY 250 HOURS SERVICE

- 5.8.7. EVERY 500 HOURS SERVICE

- 5.8.8. EVERY 1000 HOURS SERVICE

- 5.8.9. EVERY 1500 HOURS SERVICE

- 5.8.10. EVERY 2000 HOURS SERVICE

- 5.8.11. EVERY 10000 HOURS SERVICE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS, OPTIONS

- 7.1. SELECTING BUCKET AND TIRES

- 7.2. STARTING IN COLD AREAS

- 7.2.1. ELECTRIC HEATER

- 7.3. HANDLING BATTERY DISCONNECTOR SWITCH

- 7.3.1. EXPLANATION OF COMPONENT

- 7.3.2. HANDLING

- 7.4. SERVICE CENTER

- 7.5. EMERGENCY ENGINE STOP SWITCH

- 7.6. CENTRALIZED BREATHER

- 7.7. HYDRAULIC OIL LEVEL WARNING DISPLAY

- 7.8. HANDLING MACHINE EQUIPPED WITH TRAINER SEAT

- 7.8.1. GENERAL VIEW OF CONTROLS AND GAUGES

- 7.8.2. CONTROL LEVERS, PEDALS, KNOBS

- 7.8.3. HANDLING TRAINER SEAT

- 7.8.4. WHEN REQUIRED

- 8. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF