- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA30-5, WA50-3 Wheel Loader Operation and Maintenance Manual SEAM059800T

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM059800T

- Format: PDF

- Size: 6.6MB

- Number of Pages: 188

-

Model List:

- WA30-5 Wheel Loader

- WA50-3 Wheel Loader

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR,LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.4. NECESSARY INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER(PIN)/MACHINE SERIAL NO.PLATE

- 2.4.2. ENGINE SERIAL NO.PLATE AND POSITON

- 2.4.3. POSITION OF SERVICE METER

- 2.4.4. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 3. CONTENTS

- 4. SAFETY

- 4.1. SAFETY

- 4.2. SAFETY LABELS

- 4.2.1. LOCATION OF SAFETY LABELS

- 4.2.2. SAFETY LABELS

- 4.3. GENERAL PRECAUTIONS

- 4.3.1. SAFETY RULES

- 4.3.2. IF ABNORMALITIES ARE FOUND

- 4.3.3. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 4.3.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 4.3.5. SAFETY FEATURES

- 4.3.6. KEEP MACHINE CLEAN

- 4.3.7. INSIDE OPERATORS COMPARTMENT

- 4.3.8. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 4.3.9. HANDRAILS AND STEPS

- 4.3.10. MOUNTING AND DISMOUNTING

- 4.3.11. NO PEOPLE ON ATTACHMENTS

- 4.3.12. DO NOT GET CAUGHT IN ARTICULATED PORTION

- 4.3.13. PREVENTION OF BURNS

- 4.3.14. FIRE PREVENTION

- 4.3.15. ACTION IF FIRE OCCURS

- 4.3.16. WINDOW WASHER LIQUID

- 4.3.17. PRECAUTIONS WHEN USING ROPS (ROLL OVER PROTECTIVE STRUCTURE)

- 4.3.18. PRECAUTIONS FOR ATTACHMENTS

- 4.3.19. UNAUTHORIZED MODIFICATION

- 4.3.20. SAFETY AT WORKSITE

- 4.3.21. WORKING ON LOOSE GROUND

- 4.3.22. DO NOT GO CLOSE TO HIGHVOLTAGE CABLES

- 4.3.23. ENSURE GOOD VISIBILITY

- 4.3.24. BE CAREFUL ABOUT ASBESTOS DUST

- 4.3.25. CHECKING SIGNALMANS SIGNALS AND SIGNS

- 4.3.26. EMERGENCY EXIT FROM OPERATORS CAB

- 4.3.27. VENTILATION FOR ENCLOSED AREAS

- 4.4. PRECAUTIONS FOR OPERATION

- 4.4.1. STARTING ENGINE

- 4.4.1.1. CHECKS BEFORE STARTING ENGINE

- 4.4.1.2. PRECAUTIONS WHEN STARTING

- 4.4.1.3. PRECAUTIONS IN COLD AREAS

- 4.4.2. OPERATION

- 4.4.2.1. CHECKS BEFORE OPERATION

- 4.4.2.2. PRECAUTIONS WHEN TRAVELING IN FORWARD OR REVERSE

- 4.4.2.3. PRECAUTIONS WHEN TRAVELING

- 4.4.2.4. PRECAUTIONS WHEN USING A SMOKE POT

- 4.4.2.5. TRAVELING ON SLOPES

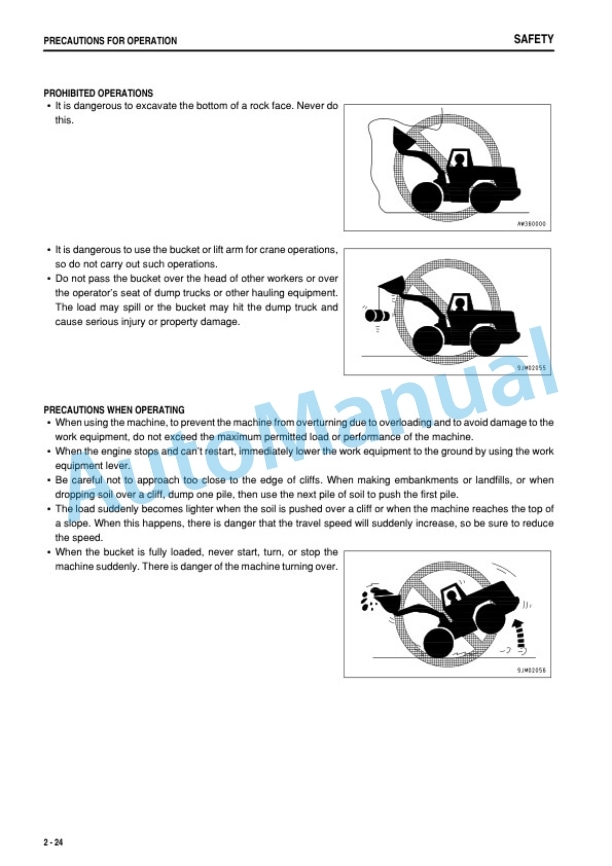

- 4.4.2.6. PROHIBITED OPERATIONS

- 4.4.2.7. PRECAUTIONS WHEN OPERATING

- 4.4.2.8. METHODS OF USING BRAKE

- 4.4.2.9. OPERATE CAREFULLY ON SNOW

- 4.4.2.10. PARKING MACHINE

- 4.4.3. TRANSPORTATION

- 4.4.3.1. LOADING AND UNLOADING

- 4.4.3.2. SHIPPING

- 4.4.4. BATTERY

- 4.4.4.1. BATTERY HAZARD PREVENTION

- 4.4.4.2. STARTING WITH BOOSTER CABLES

- 4.4.5. TOWING

- 4.4.5.1. WHEN TOWING

- 4.5. PRECAUTIONS FOR MAINTENANCE

- 4.5.1. WARNING TAG

- 4.5.2. KEEP WORK PLACE CLEAN AND TIDY

- 4.5.3. APPOINT LEADER WHEN WORKING WITH OTHERS

- 4.5.4. MAINTENANCE WITH ENGINE RUNNING

- 4.5.5. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 4.5.6. PROPER TOOLS

- 4.5.7. PERSONNEL

- 4.5.8. ATTACHMENTS

- 4.5.9. WORK UNDER THE MACHINE

- 4.5.10. NOISE

- 4.5.11. PRECAUTIONS WHEN USING HAMMER

- 4.5.12. REPAIR WELDING

- 4.5.13. REMOVING BATTERY TERMINAL

- 4.5.14. PRECAUTIONS WITH HIGHPRESSURE OIL

- 4.5.15. HANDLING HIGHPRESSURE HOSES

- 4.5.16. WASTE MATERIALS

- 4.5.17. COMPRESSED AIR

- 4.5.18. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 4.6. PRECAUTIONS WITH TIRES

- 4.6.1. HANDLING TIRES

- 4.6.2. PRECAUTIONS WHEN STORING TIRES

- 5. OPERATION

- 5.1. GENERAL VIEW

- 5.1.1. GENERAL VIEW OF MACHINE

- 5.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 5.2. EXPLANATION OF COMPONENTS

- 5.2.1. MACHINE MONITOR

- 5.2.2. SWITCHES

- 5.2.3. CONTROL LEVERS, PEDALS

- 5.2.4. CHECK BEFORE STARTING ENGINE, ADJUST

- 5.2.5. STARTING ENGINE

- 5.2.6. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 5.2.7. STOPPING ENGINE

- 5.2.8. MOVING THE MACHINE(DIRECTIONAL, SPEED), STOPPING THE MACHINE

- 5.2.9. TURNING

- 5.2.10. OPERATION OF WORK EQUIPMENT

- 5.2.11. HANDLING FRONT ATTACHMENT SERVICE HYDRAULIC CIRCUIT

- 5.2.12. WORK POSSIBLE USING WHEEL LOADER

- 5.2.13. PRECAUTIONS FOR OPERATION

- 5.2.14. ADJUSTING WORK EQUIPMENT POSTURE

- 5.2.15. PARKING MACHINE

- 5.2.16. CHECKS AFTER COMPLETION OF OPERATION

- 5.2.17. LOCKING

- 5.2.18. HANDLING THE TIRES

- 5.3. TRANSPORTATION

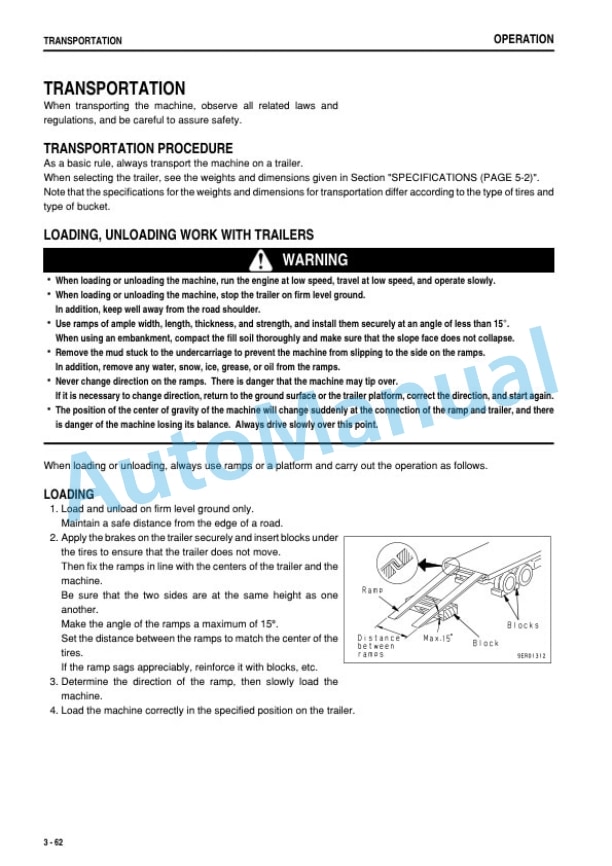

- 5.3.1. TRANSPORTATION PROCEDURE

- 5.3.2. LOADING, UNLOADING WORK WITH TRAILERS

- 5.3.3. LIFTING MACHINE

- 5.3.4. REMOVAL,INSTALLATION OF CANOPY

- 5.4. COLD WEATHER OPERATION

- 5.4.1. PRECAUTIONS FOR LOW TEMPERATURE

- 5.4.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 5.4.3. AFTER COLD WEATHER

- 5.5. LONGTERM STORAGE

- 5.5.1. BEFORE STORAGE

- 5.5.2. DURING STORAGE

- 5.5.3. AFTER STORAGE

- 5.6. TROUBLESHOOTING

- 5.6.1. WHEN MACHINE RUNS OUT OF FUEL

- 5.6.2. TOWING THE MACHINE

- 5.6.3. IF BATTERY IS DISCHARGED

- 5.6.4. OTHER TROUBLE

- 6. MAINTENANCE

- 6.1. GUIDES TO MAINTENANCE

- 6.2. OUTLINES OF SERVICE

- 6.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 6.2.2. OUTLINE OF ELECTRIC SYSTEM

- 6.3. WEAR PARTS

- 6.3.1. WEAR PARTS LIST

- 6.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 6.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 6.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 6.5.1. TORQUE LIST

- 6.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 6.7. MAINTENANCE SCHEDULE CHART

- 6.7.1. MAINTENANCE SCHEDULE CHART

- 6.8. SERVICE PROCEDURE

- 6.8.1. INITIAL 250 HOURS SERVICE OR INITIAL 3 MONTHS(ONLY AFTER THE FIRST 250 HOURS)

- 6.8.2. WHEN REQUIRED

- 6.8.2.1. REPLACE AIR CLEANER ELEMENT

- 6.8.2.2. CLEAN INSIDE OF COOLING SYSTEM

- 6.8.2.3. DRAIN WATER AND SEDIMENT FROM FUEL TANK

- 6.8.2.4. CHECK WATER SEPARATOR ELEMENT

- 6.8.2.5. CHECK OIL LEVEL IN TRANSFER CASE,ADD OIL

- 6.8.2.6. CHECK AXLE OIL LEVEL, ADD OIL

- 6.8.2.7. CLEAN TRANSFER CASE BREATHER

- 6.8.2.8. CLEAN AXLE CASE BREATHER

- 6.8.2.9. CLEAN AND CHECK RADIATOR FINS

- 6.8.2.10. TURN,REPLACE BOLTON CUTTING EDGE

- 6.8.2.11. CHECK PARKING BRAKE

- 6.8.2.12. ADJUST PARKING BRAKE RELEASE LEVER

- 6.8.2.13. CHECK BRAKE PEDAL

- 6.8.2.14. SELECTION AND INSPECTION OF TIRES

- 6.8.3. CHECK BEFORE STARTING

- 6.8.4. EVERY 50 HOURS SERVICE OR EVERY 1 MONTH

- 6.8.4.1. CLEAN AIR CLEANER DUST CUP

- 6.8.5. EVERY 250 HOURS SERVICE OR EVERY 3 MONTHS

- 6.8.5.1. LUBRICATING

- 6.8.5.2. CHECK OIL LEVEL IN HYDRAULIC TANK,ADD OIL

- 6.8.5.3. CLEAN AIR CLEANER ELEMENT

- 6.8.5.4. CHECK FAN BELT TENSION,ADJUST

- 6.8.5.5. CHECK BATTERY ELECTROLYTE LEVEL

- 6.8.5.6. CHECK FOR LOOSE WHEEL HUB BOLTS,TIGHTEN

- 6.8.6. EVERY 500 HOURS SERVICE OR EVERY 6 MONTHS

- 6.8.6.1. LUBRICATE REAR AXLE PIVOT PIN(2 PLACES)

- 6.8.6.2. REPLACE FUEL FILTER CARTRIDGE

- 6.8.6.3. CHANGE OIL IN ENGINE OIL PAN,REPLACE ENGINE OIL FILTER CARTRIDGE

- 6.8.7. EVERY 1000 HOURS SERVICE OR EVERY 1 YEAR

- 6.8.7.1. CHANGE OIL IN HYDRAULIC TANK,REPLACE HYDRAULIC OIL FILTER CARTRIDGE AND HST FILTER ELEMENT

- 6.8.7.2. LUBRICATING

- 6.8.8. EVERY 2000 HOURS SERVICE OR EVERY 2 YEARS

- 6.8.8.1. CHANGE OIL IN TRANSFER CASE

- 6.8.8.2. CHANGE AXLE OIL

- 6.8.8.3. CHECK ALTERNATOR,STARTING MOTOR

- 6.8.8.4. CHECK ENGINE VALVE CLEARANCE,ADJUST

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS

- 8. ATTACHMENTS, OPTIONS

- 8.1. HANDLING SEAT BELT

- 8.1.1. FASTENING AND REMOVING BELT

- 8.1.2. ADJUST BELT LENGTH

- 8.1.3. CHECK SEAT BELT AND MOUNTS

- 8.2. HANDLING SERVICE HYDRAULIC CIRCUIT

- 8.2.1. CONNECTING HYDRAULIC CIRCUIT

- 8.2.2. ROUTE OF HYDRAULIC CIRCUIT

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF