Table of Content:

1 ELECTRONIC MANUALS

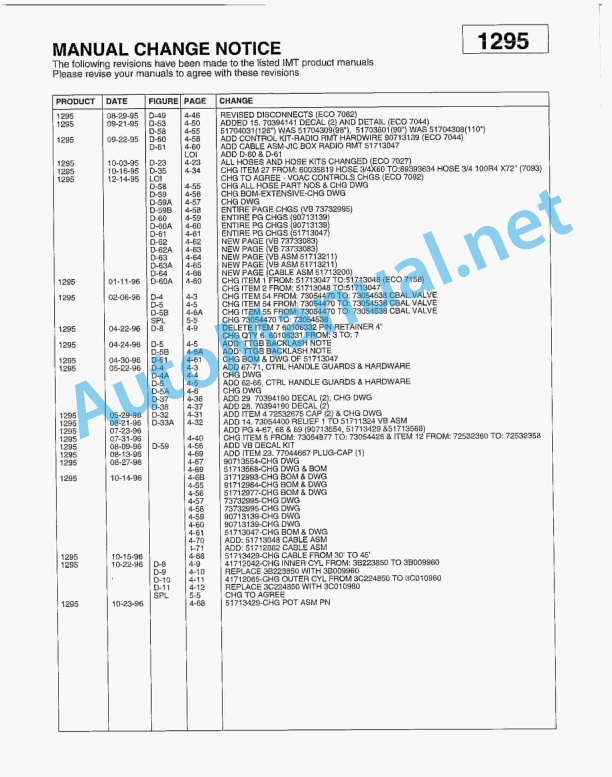

2 REVISIONS LIST

3 PRECAUTIONS

4 TABLE OF CONTENTS

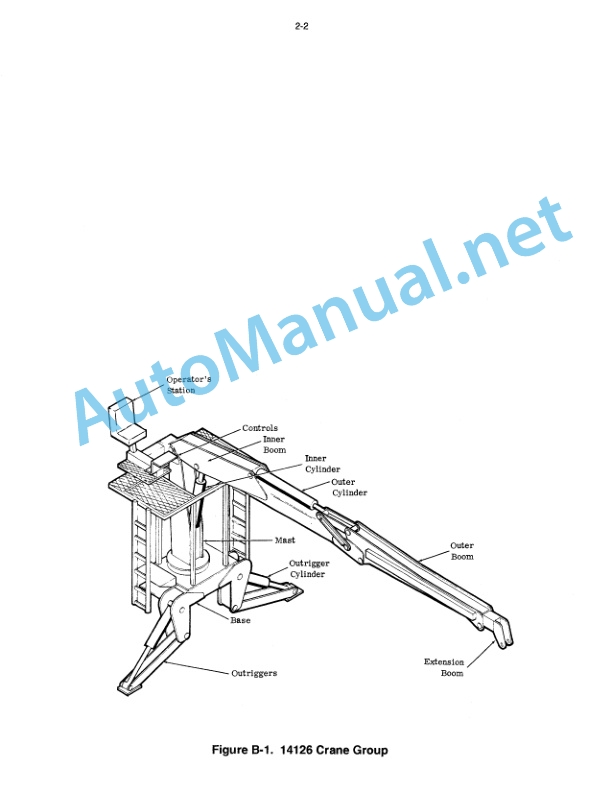

5 Section 1. INTRODUCTION AND SPECIFICATIONS

5.1 1-1. INTRODUCTION

5.2 1-2. ORDERING INFORMATION

5.3 1-3. GENERAL INFORMATION

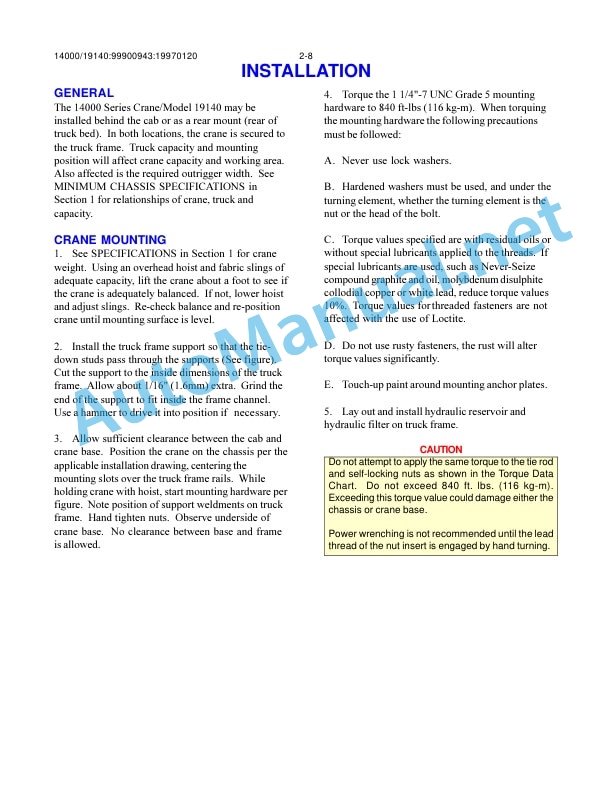

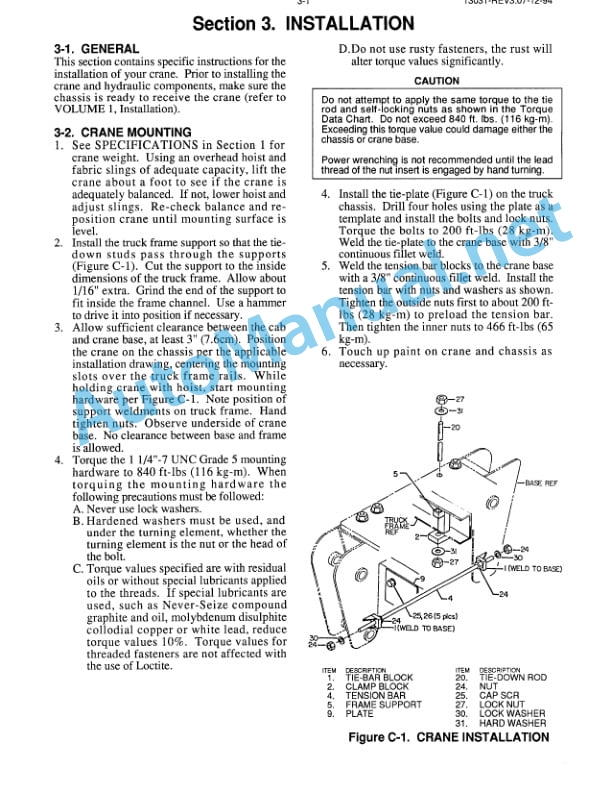

6 Section 2. INSTALLATION

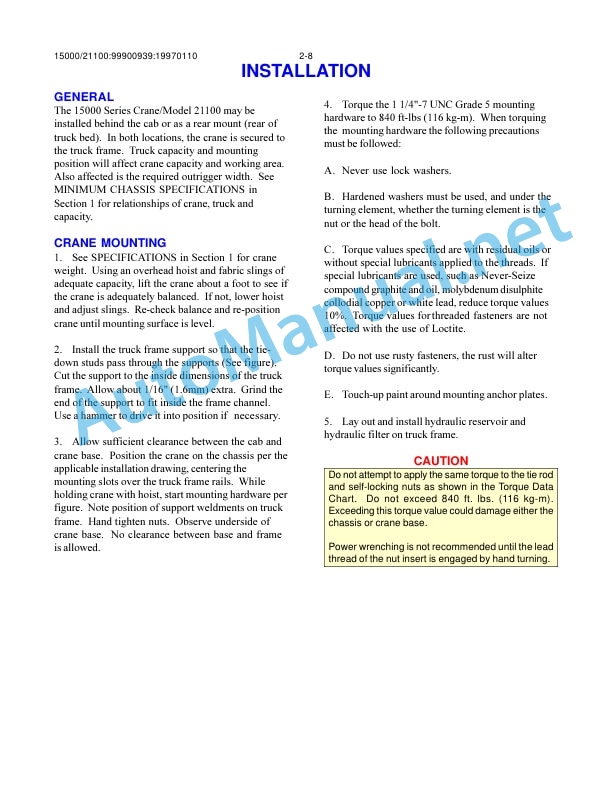

6.1 2-1. GENERAL

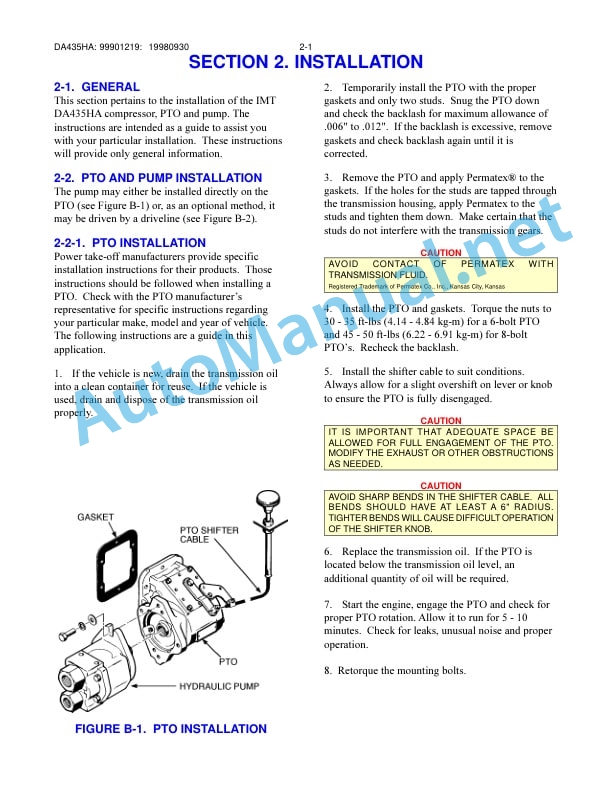

6.2 2-2. PTO AND PUMP INSTALLATION

6.3 2-2-1. PTO INSTALLATION

6.4 FIGURE B-1. PTO INSTALLATION

6.5 2-2-2. DRIVELINE AND PUMP INSTALLATION

6.6 2-3. COMPRESSOR INSTALLATION

6.7 FIGURE B-2. DRIVELINE & PUMP INSTALLATION

6.8 2-4. DRIVELINE INSTALLATION TECHNIQUES

6.9 2-4-1. U-JOINT OPERATING ANGLES

6.10 2-4-2. SINGLE PLANE AND COMPOUND U-JOINT OPERATING ANGLES

6.11 2-4-3. ELIMINATING COMPOUND ANGLE INDUCED VIBRATIONS

6.12 2-4-4. ANGLE SIZE

7 SECTION 3. OPERATION

7.1 3-1. GENERAL

7.2 3-2. OPERATION

8 Section 4. MAINTENANCE & PARTS

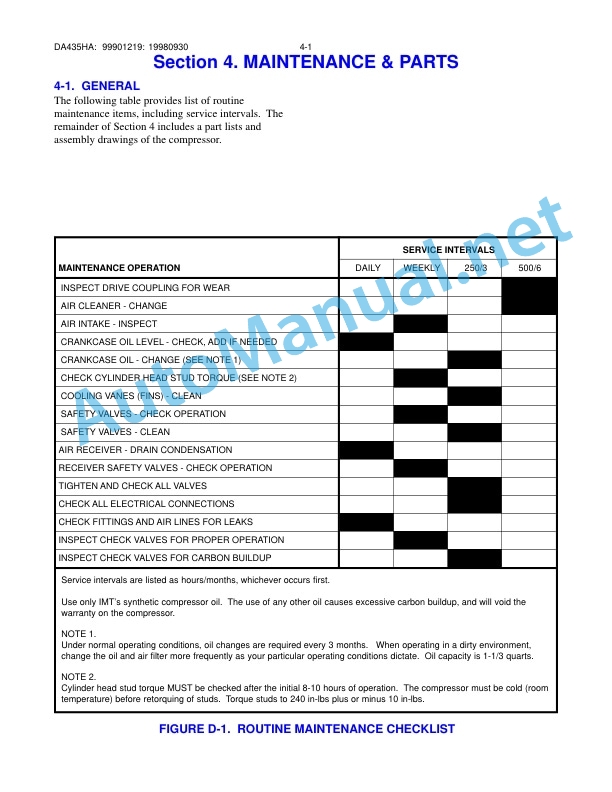

8.1 4-1. GENERAL

8.2 FIGURE D-1. ROUTINE MAINTENANCE CHECKLIST

8.3 OIL COOLING SYSTEM (200057)

8.4 COMPRESSOR MTG SYSTEM (200056-1)

8.5 COMPRESSOR ASM (200056-2)

8.6 COMPRESSOR ASM (200056-3)

8.7 COMPRESSOR ASM (200056-4)

8.8 CANOPY SYSTEM

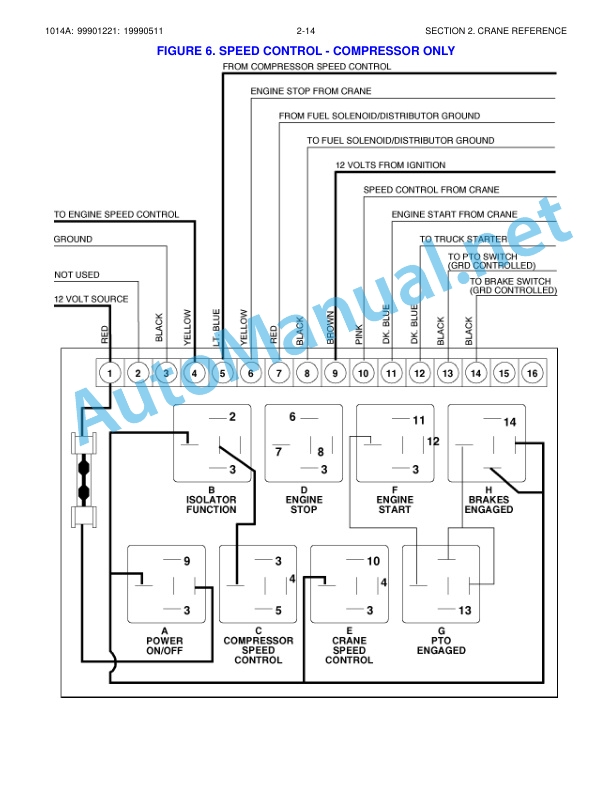

8.9 COMPRESSOR WIRING DIAGRAM

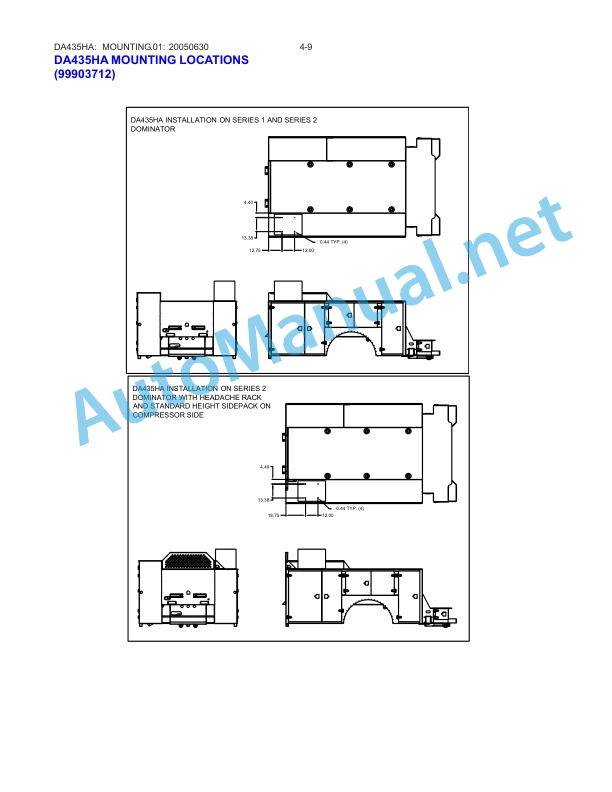

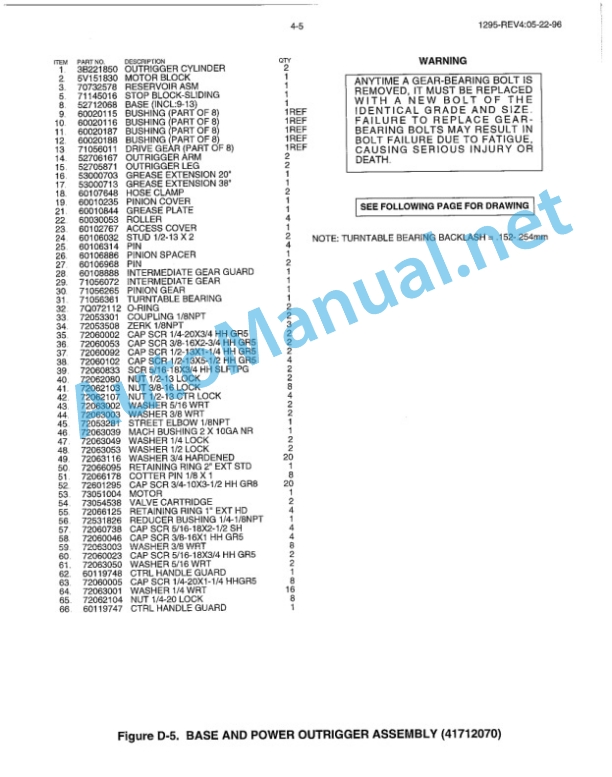

8.10 DA435HA MOUNTING LOCATIONS (99903712)

8.11 INSTALLATION KIT (51712642) (THROUGH 3-15-05)

8.12 INSTALLATION KIT (51712642) (EFFECTIVE 3-15-05)

8.13 COMPRESSOR HARNESS CHART

8.14 HARNESS (304710) EFFECTIVE 3/15/05

8.15 DECAL PLACEMENT (80015)

8.16 HYDRAULIC INSTALLATION KIT (91707052)

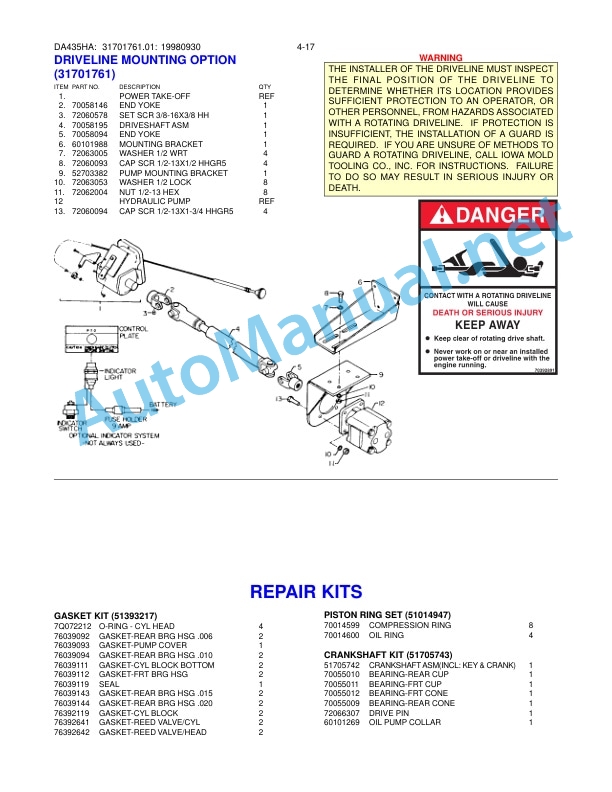

8.17 DRIVELINE MOUNTING OPTION (31701761)

8.18 REPAIR KITS

8.19 RECOMMENDED SPARE PARTS LIST

9 SECTION 5. REPAIR

9.1 5-1. GENERAL

9.2 5-2. PISTON RING REPLACEMENT

9.3 FIGURE E-1. PISTON RING ORIENTATION

9.4 FIGURE E-2. CYLINDER HEAD TORQUE SEQUENCE

9.5 5-3. OIL PUMP REPLACEMENT

9.6 5-4. CRANKSHAFT AND BEARING REPLACEMENT

9.7 FIGURE E-3. BEARING HOUSING TORQUE SEQUENCE

9.8 FIGURE E-4. ROD ALIGNMENT

9.9 5-5. TROUBLESHOOTING

9.10 FIGURE E-5. TROUBLESHOOTING CHART

9.11 5-6. REED VALVE REPLACEMENT